Replace the cooling fan belt tensioner

WARNING

EXPLOSION HAZARD!

Batteries can emit explosive gases.

To reduce the possibility of personal injury, always ventilate the

compartment before servicing the batteries. To reduce the possibil‐

ity of arcing, remove the negative (-) battery cable first and attach

the negative (-) battery cable last.

Remove

1 Disconnect the battery cables. Refer to the original equipment

manufacturer (OEM) service manual.

2 Remove the drive belt, see Chapter

1.7 Cooling system

, para‐

graph

Replace the cooling fan drive belt

.

3 Remove the capscrew and belt tensioner from the bracket.

NOTE

Most belt tensioners are mounted to the water inlet connection.

Some belt tensioners are mounted to a separate mounting bracket

and use internal fasteners for clearance.

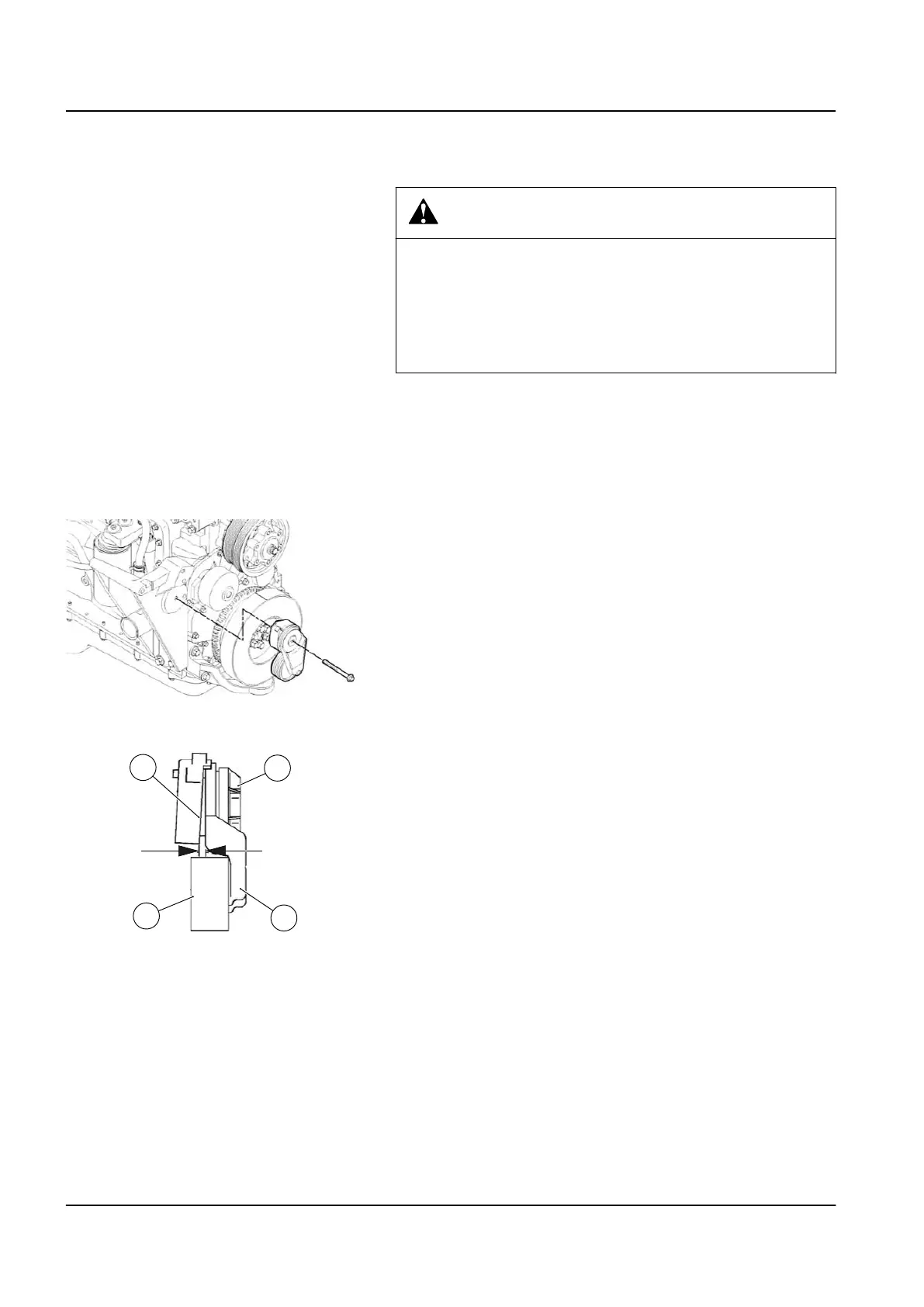

Examine for reuse

1 Measure the clearance between the tensioner spring case

and the tensioner arm to verify tensioner wear-out and

uneven bearing wear. If the clearance at measurement point

(X) is more than 3 mm (0.12 in) at any point, the tensioner is

damaged and must be replaced as a complete assembly.

NOTE

Always replace the belt when a tensioner is replaced. However, it is

not always necessary to replace a tensioner when a belt is replaced.

A. Tensioner cap

B. Tensioner arm

C. Spring case

D. Tensiner pulley

32 1 Engine – 1.7 Cooling system

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...