English 97

3. Maintenance work may only be carried out by approved cus-

tomer service sites or qualified staff in this field who are famil-

iar with all the relevant safety instructions.

4. Any welding work on the vehicle or attachments must be per-

formed by the authorised Kärcher Customer Service.

Service indicator

The service indicator lights up when the respective maintenance

needs to be done.

The service indicator flashes on the display:

after 50 operating hours when the initial inspection needs to be

performed.

Next service after 250 operating hours.

Then every 500 operating hours.

Note

The service indicator must be reset by the Customer Service.

Maintenance intervals

Note

In order to preserve warranty claims, all servicing and mainte-

nance work during the warranty period has to be performed by an

authorised Kärcher Customer Service, in accordance with the in-

spection check list.

Daily before starting operation, see chapter Safety checks be-

fore startup.

Lubricate all bearings after washing the vehicle.

If necessary have the safety checks according to the applica-

ble local regulations performed by the Customer Service de-

partment.

The intervals for inspection and maintenance work to be per-

formed by the customer are listed in the following table.

Additional maintenance work is to be carried out by the Cus-

tomer Service department in accordance with the inspection

checklist after 250, 500 (annually), 1000, 1500 or 2000 oper-

ating hours. Please inform the Customer Service department

in time.

Vehicle maintenance plan

Vehicle lubrication plan

ATTENTION

Malfunctions

Keep the V-belt clean and free of grease.

1 Use high-grade multi-purpose grease.

2 Lubricate the grease nipples in accordance with the lubricating

intervals (Table) using a grease gun.

Daily Weekly

Lubricate all bearings specified in the lu-

brication plan.

(8h)

Check all Bowden cables and moving

parts for freedom of movement.

X

Check the side brushes and suction

mouth for wear and tangled pieces of

tape (for sweepers).

X

If the device has been operated with the

water circulation system switched off

(option), clean the filter and valve of the

water circulation system to ensure relia-

ble operation of the water circulation

system and prevent damage.

X

Check the rollers at the suction mouth

for freedom of movement (for sweep-

ers).

X

Check the spray pattern of the brush ir-

rigation spray nozzles and in the suction

mouth. Clean or replace the nozzles if

necessary (for sweepers).

X

Check all hoses and cable clamps. X

Check the coolant hoses. X

Clean the cooler fins on the water cool-

er, oil cooler and air-conditioning sys-

tem.

X

Check the V-belts and V-belt tension. X

Check that the parking brake functions

correctly and is correctly adjusted.

X

Check the engine air filter. X

Clean cooler grille. X

Check the air-conditioning system. X

Check the exhaust system. X

Clean the blower chamber. X*

Clean the waste container and cover. X*

* several times daily in the case of heavy

soiling

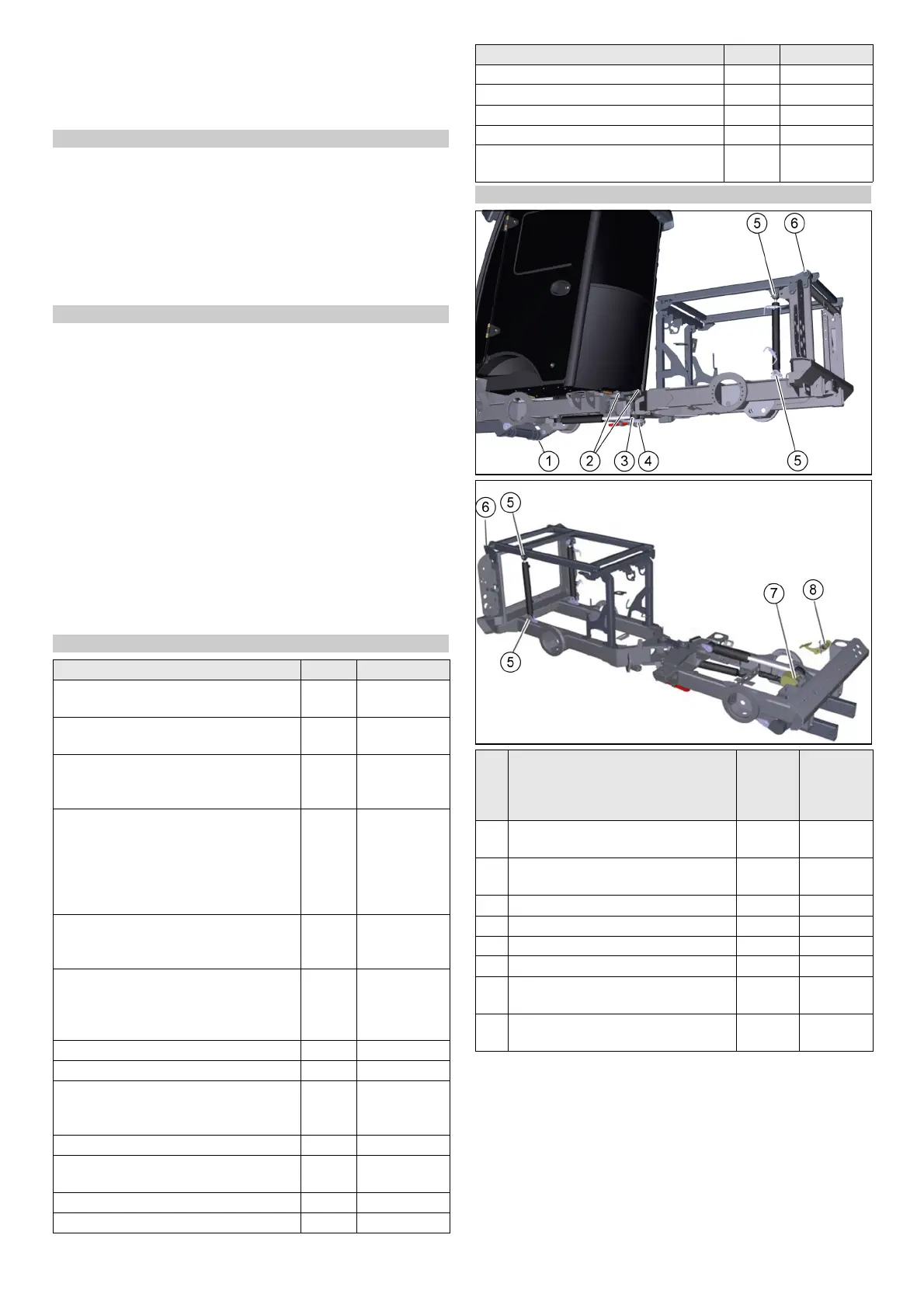

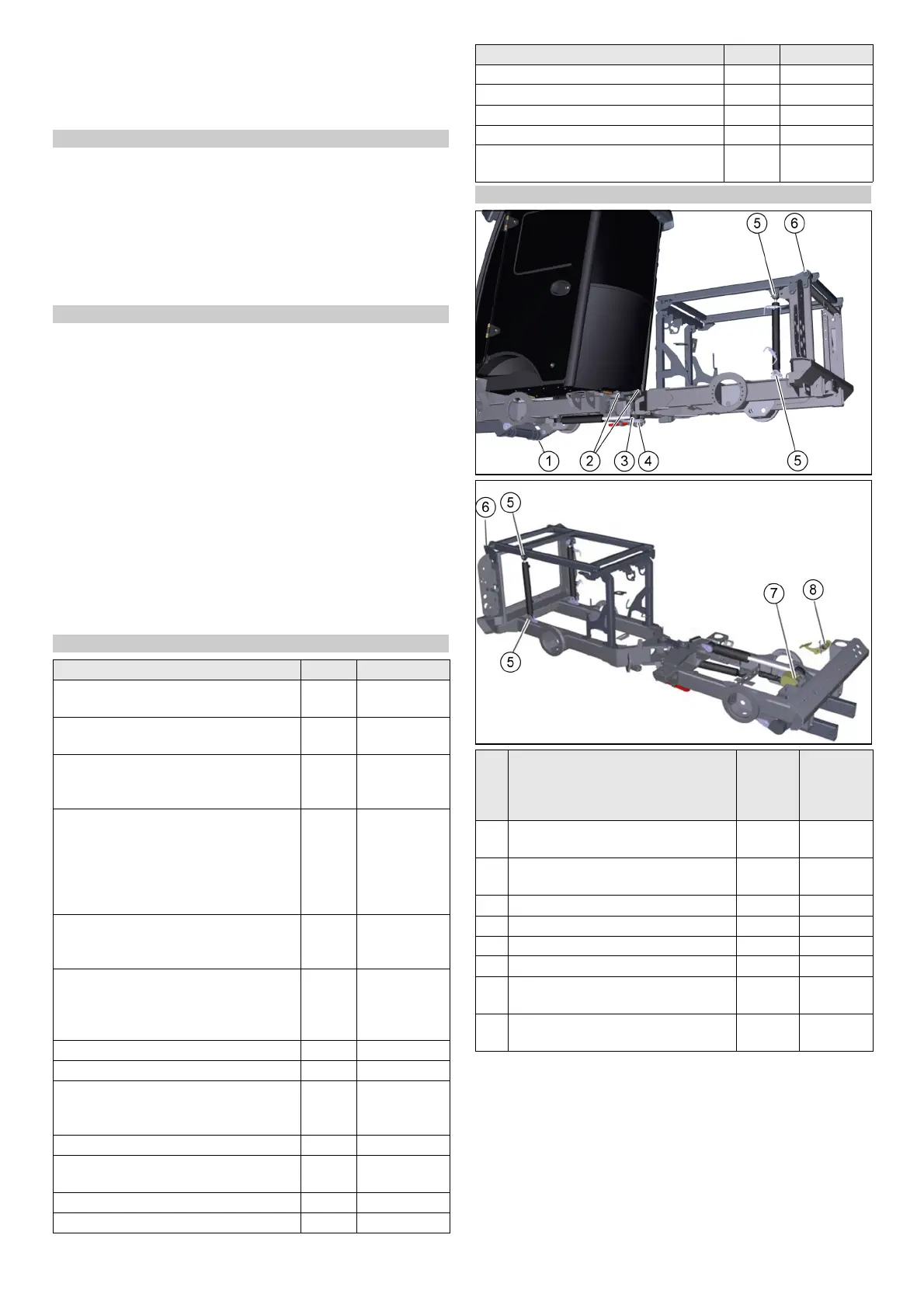

Lubrication point Number

of lubri-

cation

points

Lubrica-

tion inter-

val

1 Front power lifter slew bearing and

lifting cylinder

1 each Every 8 h

2 Articulated steering at centre of vehi-

cle

2 Every 8 h

3 Steering cylinder 2 Every 8 h

4 Lower articulated joint bearing 1 Every 8 h

5 Lifting cylinder 4 Every 25 h

6 Lifting platform 2 Every 8 h

7 Accelerator 1 Every 100

h

8 Brake pedal deflection lever 1 Every 100

h

Daily Weekly

Loading...

Loading...