32 (37)

Kemppi OY

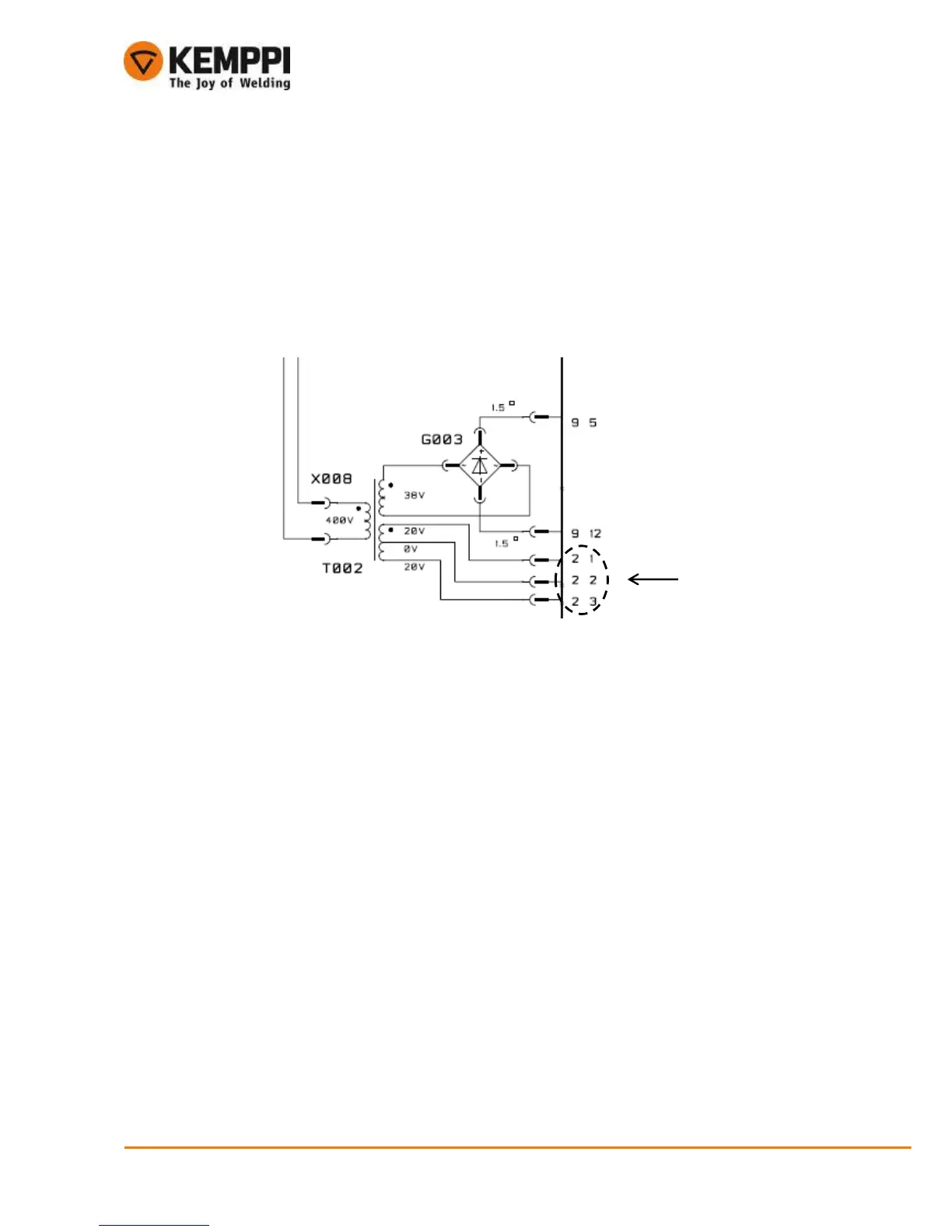

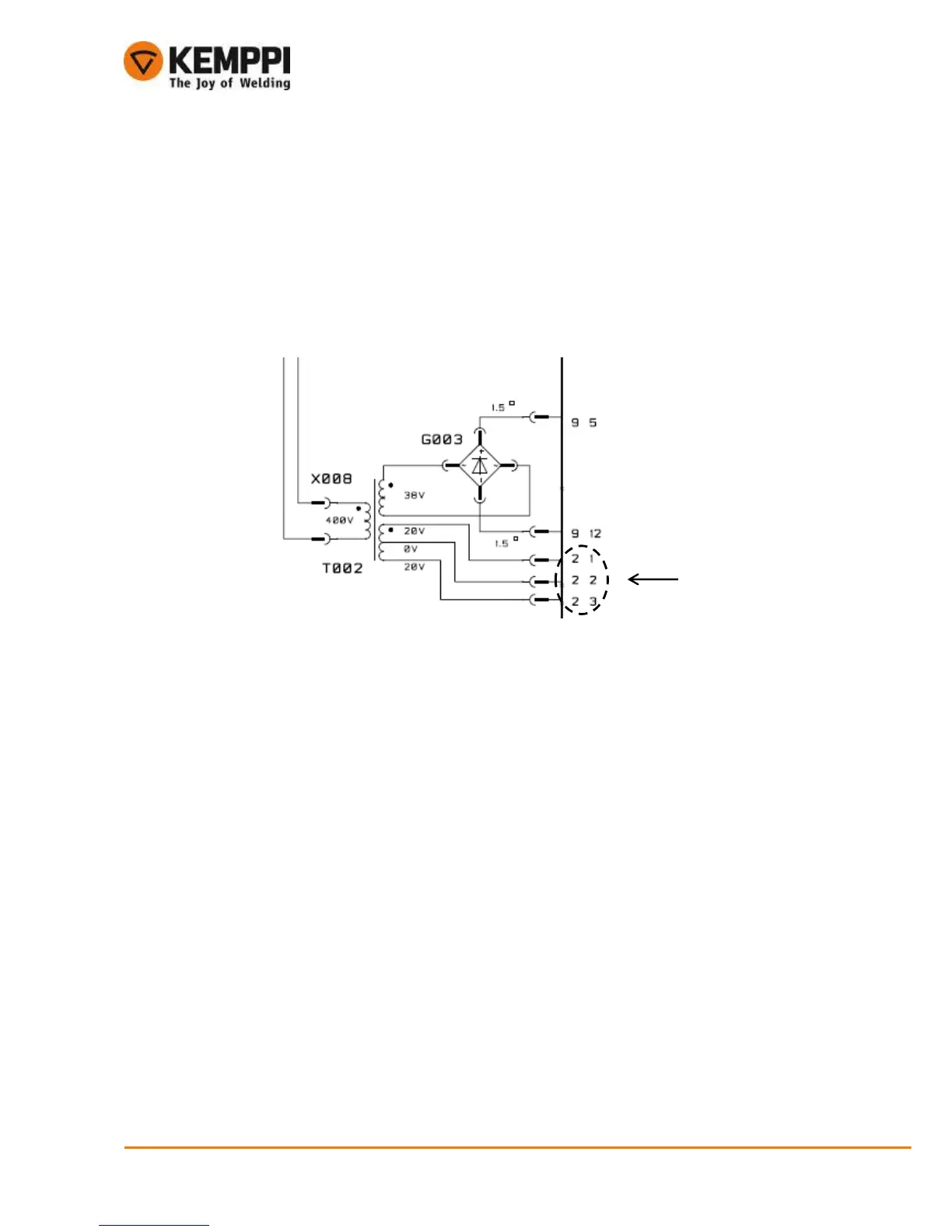

4. LOW VOLTAGE TEST

• Low voltage test gives basic information where machine has fault. Machine can switch on from auxiliary transformer

secondary winding to control blocks and via primary winding to DC link

• After replacing components it’s recommended to start machine with low voltage test

Measuring:

• Input 20VAC (Kemppi Multipower) to aux. transformers connector X2 pins 1-2 or 2-3

o voltage goes thought secondary winding to primary side as 400VAC

o voltage goes also to another secondary coil as 38VAC

o machine starts up and DC link voltage can be measured Z002 X1 and X3

5. MAIN COMPONENTS INSTALLATION

• Heat sink paste should be spread on to the modules in an even layer by using clean fingers. Then the card should be

immediately mounted onto the heat sink, this minimizes the possibility of any contamination (dirt etc.) getting

between the components.

• Use torque screwdriver when tightening any power components onto the heat sink. See following sections for

tightening torques.

5.1. Main circuit card Z001

• Primary rectifier to heat sink 2 NM

• IGBT unit to heat sink

o First step 2 NM and wait a couple minutes

o Second step 3 NM

5.2. Secondary rectifier card Z003

• Secondary diodes to heat sink 1,2 NM

• Resistors to heat sink 0,7 NM

5.2. Cut off card Z004

• Mosfet to heat sink 1,2 NM

Loading...

Loading...