26 – Promig 530 / 0612 © kemPPi oy

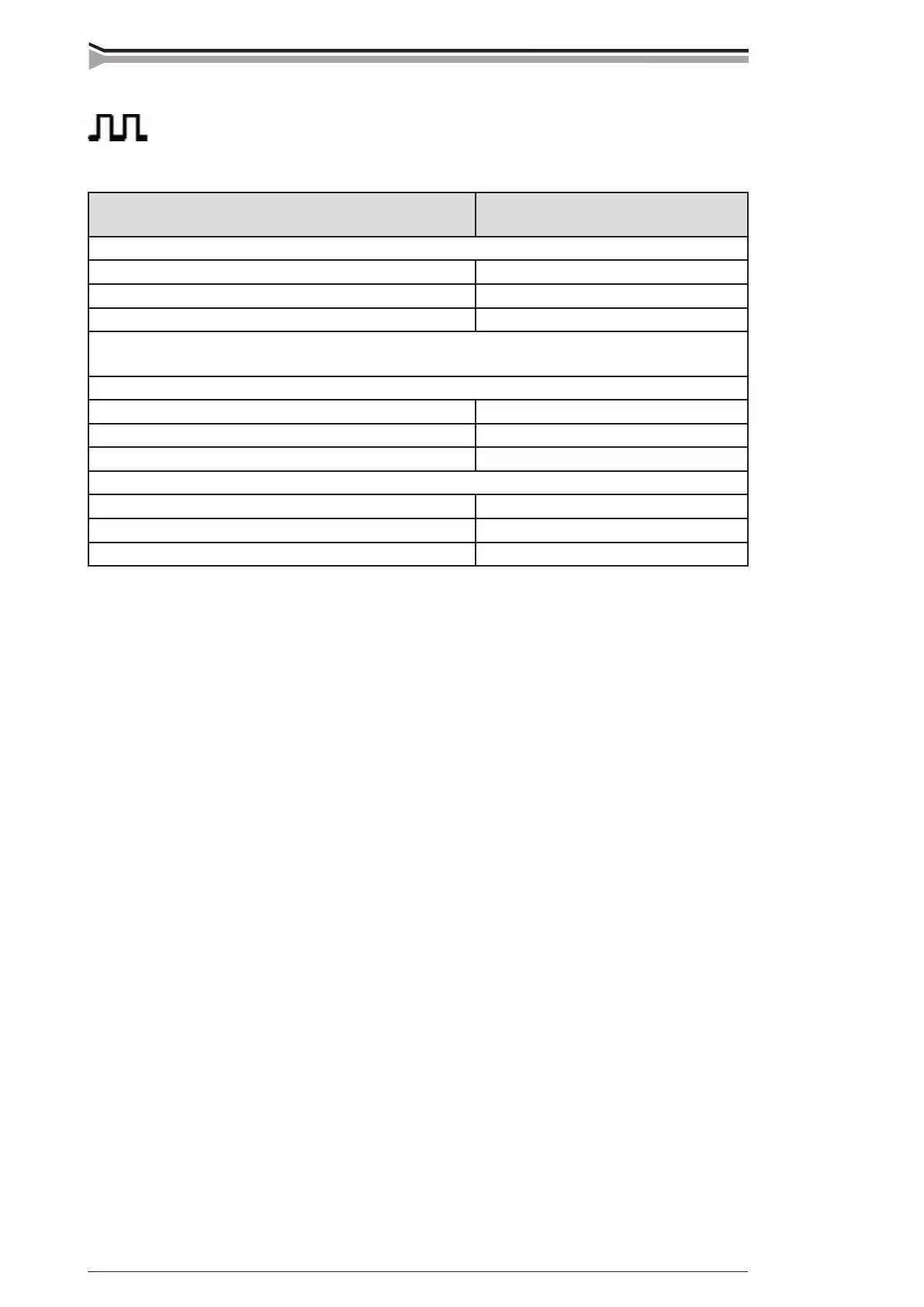

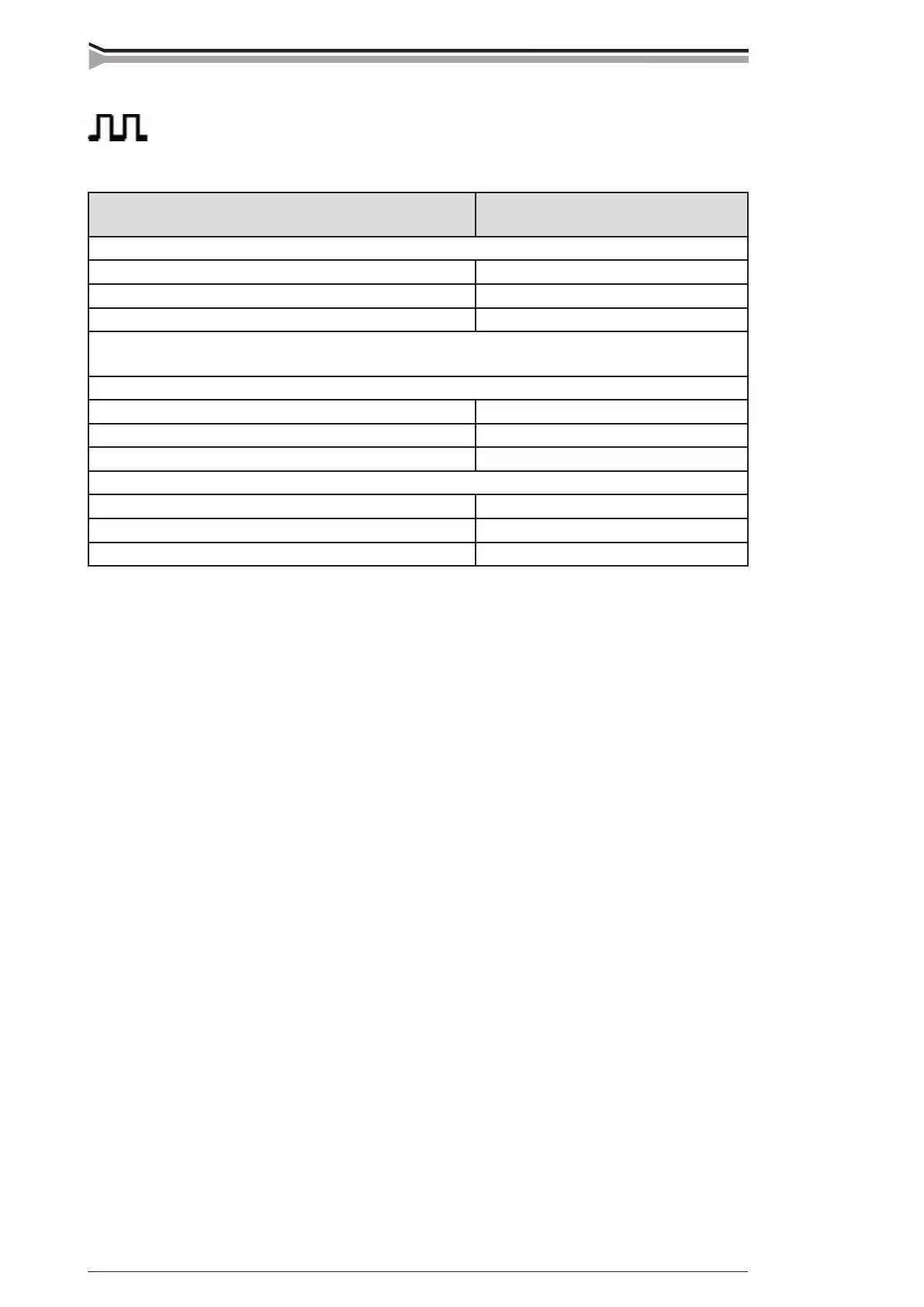

Filler wire Shielding gas

Pulsed MIG welding of steel

ø 1,0 mm, solid wire 75...82 % Ar + 25...18 % CO

²

ø 1,2 mm, solid wire 75...82 % Ar + 25...18 % CO

²

ø 1,2 mm, metal cored wire 75...82 % Ar + 25...18 % CO

²

Note!

CO

2

-per cent: with PRO 3000 power source max. 2 % with PRO 4000, max. 10 %

Pulsed MIG welding of stainless steel

ø 0,8 mm, 316, 308 97,5...98 % Ar + 2,5...2 % CO

²

/O

²

ø 1,0 mm, 316, 308 97,5...98 % Ar + 2,5...2 % CO

²

/O

²

ø 1,2 mm, 316, 308 97,5...98 % Ar + 2,5...2 % CO

²

/O

²

Pulsed MIG welding of aluminium

ø 1,0 mm, AlMg5, AlSi5 100 % Ar

ø 1,2 mm, AlMg5, AlSi5, Al99,5 100 % Ar

ø 1,6 mm, AlMg5, AlSi5, Al99,5 100 % Ar

Cable compensation is adjusted for each cable / MIG welding gun combination only once.

SYNERGIC PULSED MIG, pulsed MIG welding with parameters which are optimized

according to ller wire parameters. Nine SYNERGIC PULSED MIG programs for

different ller wires are stored:

In SYNERGIC PULSED MIG welding the welding values are adjusted with power potentiometer

(normally potentiometer for wire feed speed), arc length potentiometers (normally voltage

potentiometer) and welding dynamics potentiometer. Min. and max. power optimized for each

wire correspond to min. and max. setting of power adjustment potentiometer. Set values connected

with these min. and max. powers are shown in set value displays.

Compensating cable length

See the paragraph: ”SYNERGIC MIG welding”.

Loading...

Loading...