4.1.4 Feeding the filler wire

Ensure that the groove of the feed roll matches the diameter of ller wire used. Release

the wire end from the spool and cut o any deformed section. Be careful the wire does

not spill from the spool sides

1. Connect the welding gun and tighten the collar.

2. Straighten about 20 cm of ller wire and ensure the tip has no sharp edges. File if

necessary, as a sharp wire edge may damage the wire gun liner – particularly softer

plastic liners.

3. Present the ller wire tip to the back of the wire feed rolls and press the wire inch

switch on the wire feed panel. Feed the wire to the gun contact tip and prepare to

weld.

4. Press the Wire Inch button and allow the ller wire to feed through the gun cable to

the contact tip.

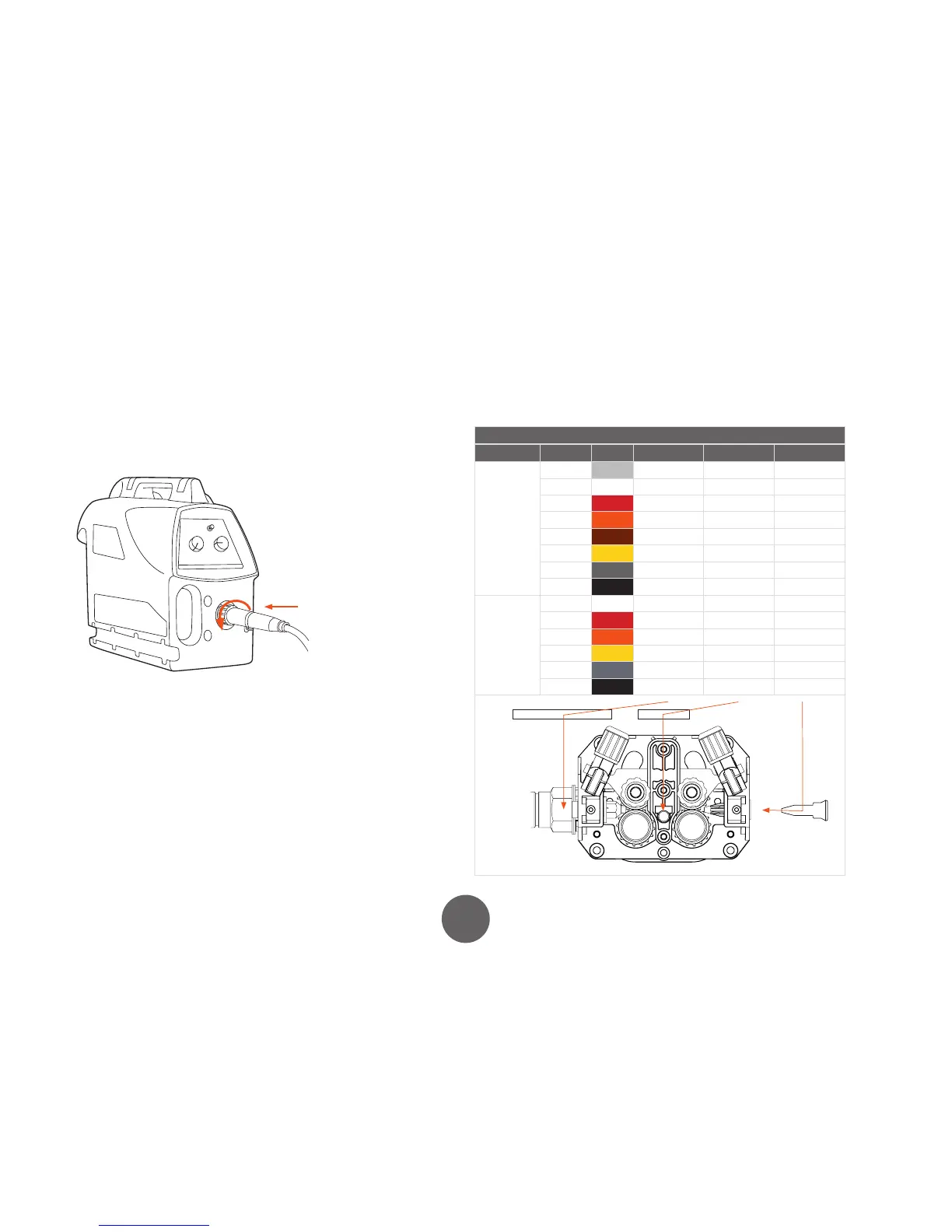

4.1.5 Wire feed mechanism DuraTorque 400

Wire guide tubes

ø mm colour outlet tube middle tube inlet tube

Ss, Al,

(Fe, Mc, Fc)

plastic

0.6 SP007437 SP007429 SP007293

0.8 – 0.9 SP007438 SP007430 SP007294

1.0 SP007439 SP007431 SP007295

1.2 SP007440 SP007432 SP007296

1.4 SP007441 SP007433 SP007297

1.6 SP007442 SP007434 SP007298

2.0 SP007443 SP007435 SP007299

2.4 SP007444 SP007436 SP007300

Fe, Mc, Fc

metal

0.8 – 0.9 SP007454 SP007465 SP007536

1.0 SP007455 SP007466 SP007537

1.2 SP007456 SP007467 SP007538

1.4 – 1.6 SP007458 SP007469 SP007539

2.0 SP007459 SP007470 SP007540

2.4 SP007460 SP007471 SP007541

Loading...

Loading...