4. OPERATION

4.1 Loading the ller wire

4.1.1 Mounting and locking the wire spool

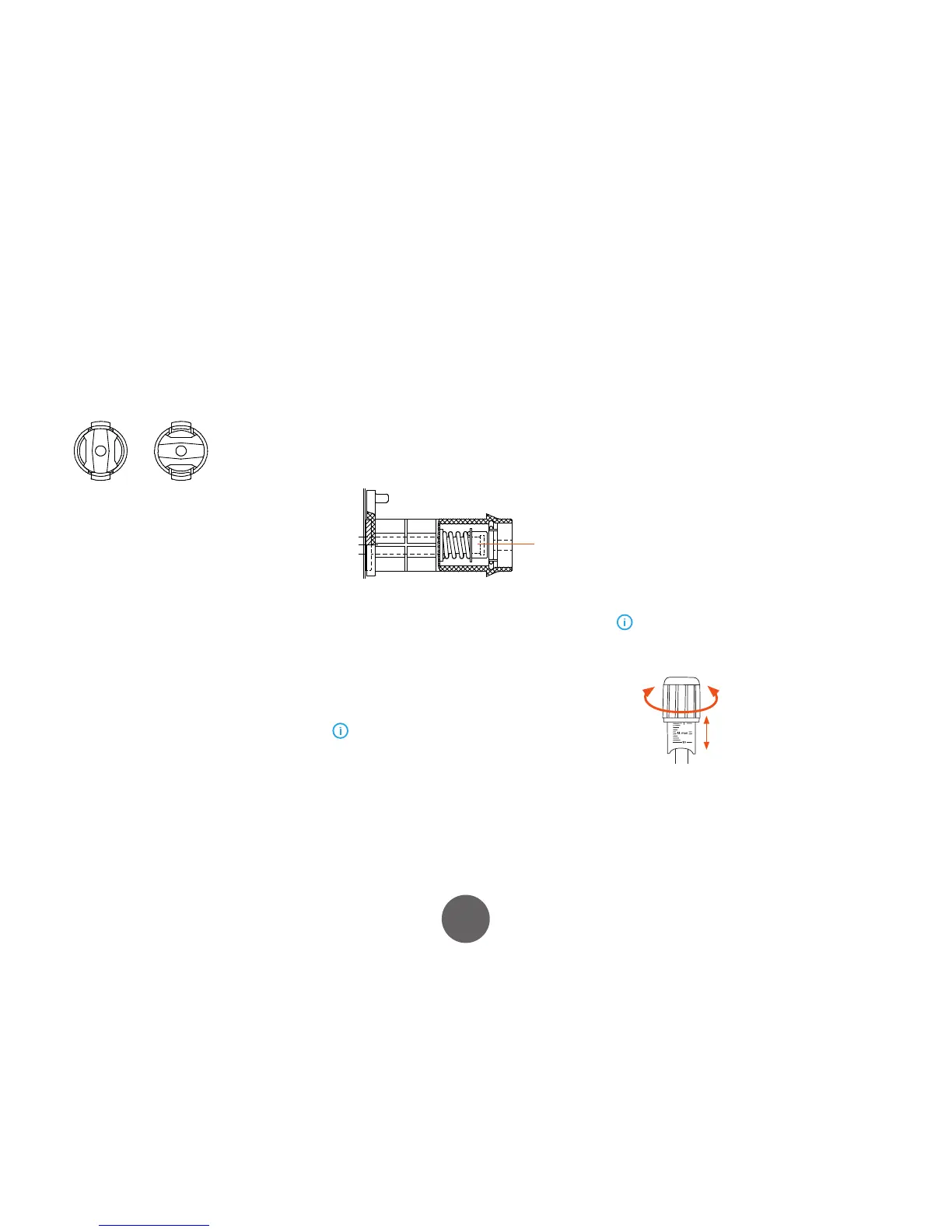

LOCKED OPEN

• Release locking nails of wire spool hub by

turning locking knob a quarter round.

• Mount the spool at its place. Note rotating

direction of spool!

• Lock the spool with locking knob, locking nails

of hub remain to outside position and will lock

the spool.

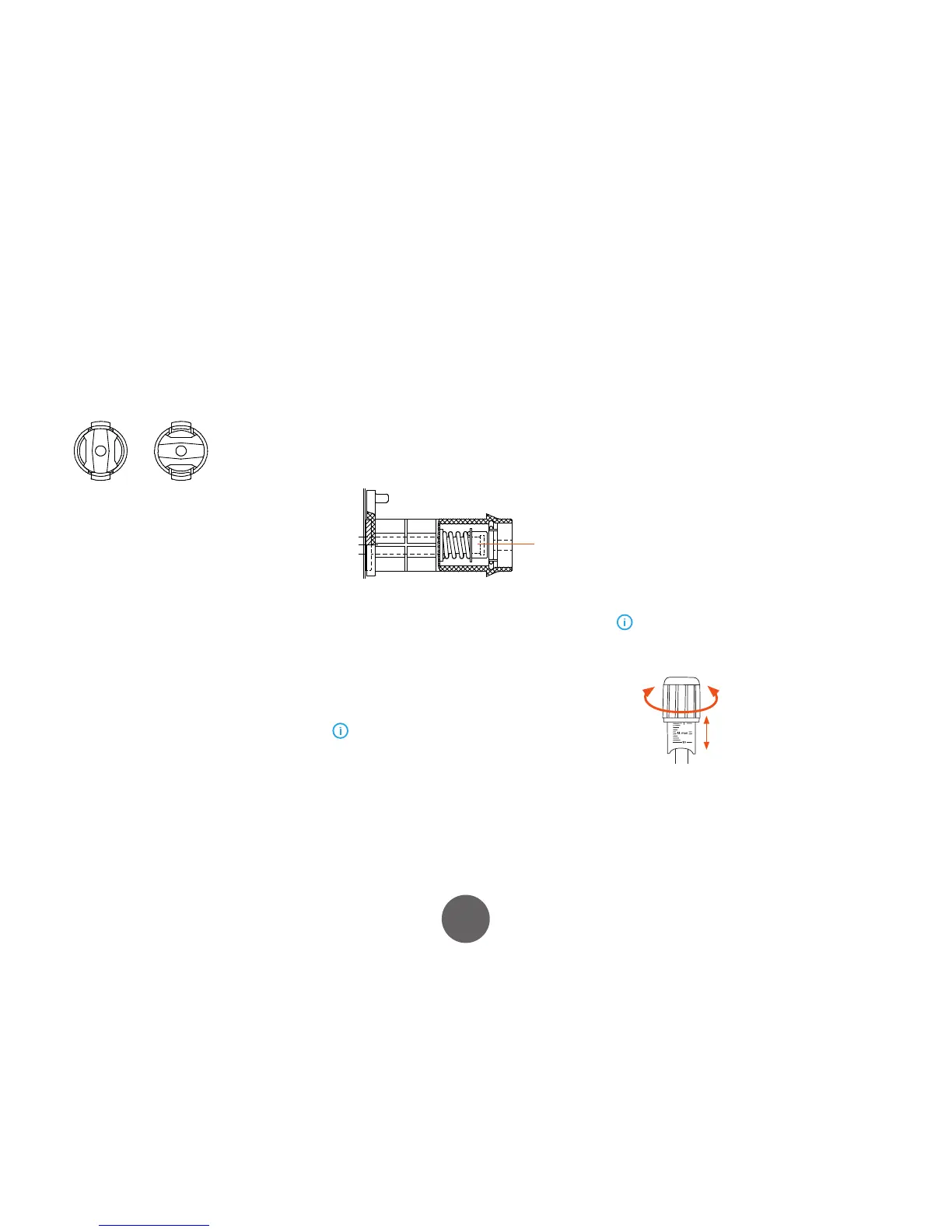

4.1.2 Adjusting the spool brake

Brake force is adjusted through the hole behind the

locking clip. Remove the locking clip by hand, and adjust

the tension and pressure to the friction pads mounted

inside with a screw driver. See diagram and location A.

A

The load applied varies depending on the size and weight

of the ller wire and spool, but also on the wire feed

speed. The heavier the wire spool and the faster the feed

speed, the greater the need to increase the braking load.

Adjust the pressure, secure the locking clip, set the wire

feed speed and check that the braking force is enough

to ensure the ller wire does not spill from the spool on

overrun.

Too much or unnecessary loads can impact welding

quality, load and wear to the wire feed system.

4.1.3 Adjusting the pressure arms

Adjust the drive pressure to the ller wire with the thumb

screws mounted over the pressure arms. Notice the grad-

uated scales indicating load. The load applied should be

sucient to overcome a light braking force applied by

hand to the ller wire, as it exits the welding gun contact

tip.

For smaller diameter and soft ller wires, less feed pres-

sure is required. It should be possible to apply a light

breaking force to the ller wire by hand, as it exits the gun

contact tip. But slightly more wire ow restriction should

render the drives rolls to slip slightly over the ller wire

without deforming the wire.

Excessive pressure causes attening of the ller wire

and damage to coated or cored ller wires. It also causes

undue wear of the feed rolls and increases gearbox load, so

reducing service life.

Loading...

Loading...