GENERAL

1-5

S196-WOO Jul. 2003

3. GENERAL PRECAUTIONS

196W104A

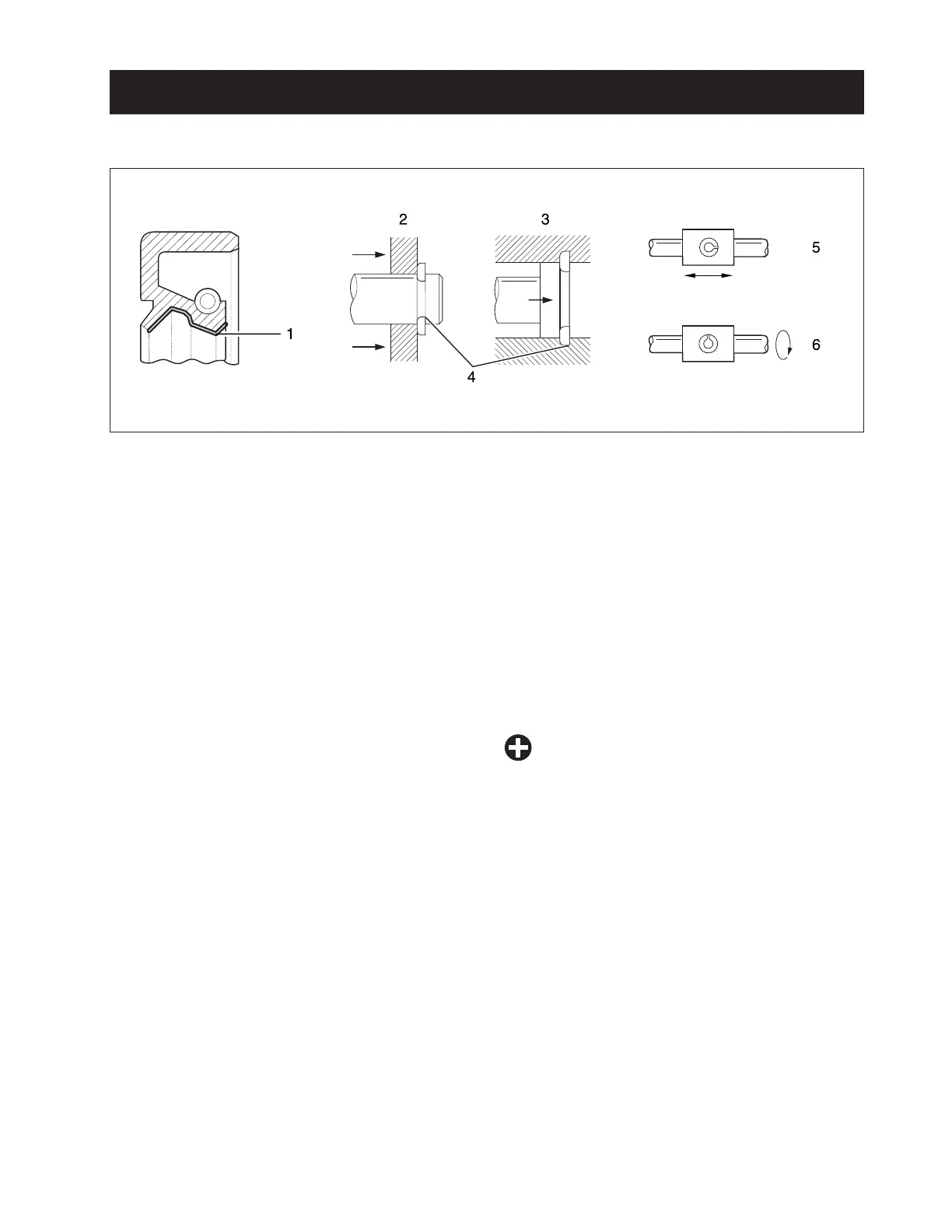

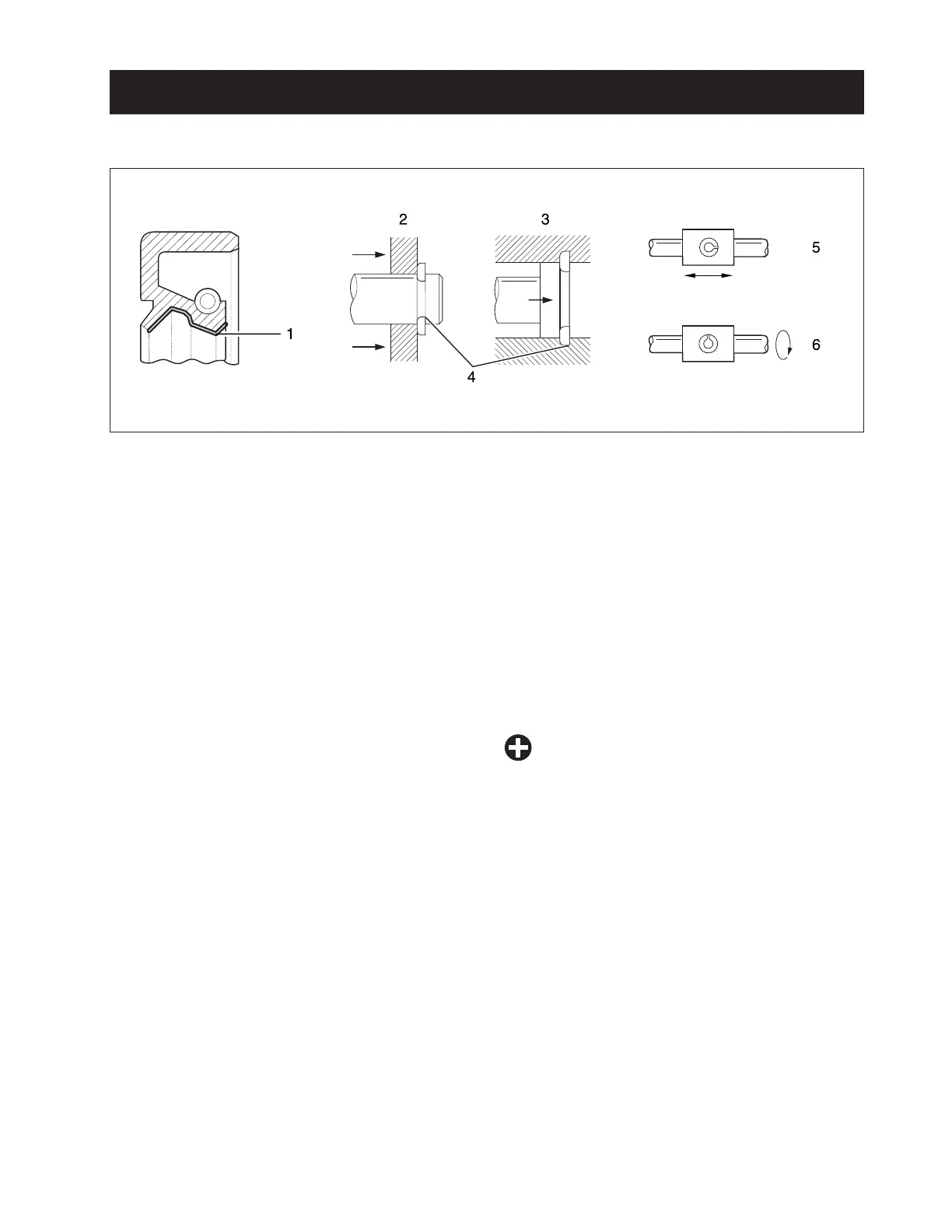

(1) Grease

(2) Snap Ring for Shaft

(3) Snap Ring for Hole

(4) Assemble Towards to be Forced

(5) Reciprocating

(6) Rotating

1. Place the tractor on the flat surface for adjustment

or service.

2. Please work with the engine stop except for the case

that must be worked with the engine running.

3. Arrange each part properly on the clean space for

disassembly. For bolts and nuts, tighten manually

by hand to its original position.

4. Use only the approved special tool. For the tool that

is not used often, use the tool made by each ser-

vice workshop.

5. Use only part cleaning agent for manufacturing

when any part needs to be clean. Do not use the

diesel oil for cleaning to prevent any pollution. Use

only approved fluid oil for cleaning any hydraulic part.

6. Be careful not to attach any dust or metal chip etc.

for disassembly and assembly of any hydraulic part.

7. For measuring any part, remove any oil or polluted

material before performing the measurement.

8. Disconnet the battery negative (-) cable before re-

moving or installing the live components.

9. Use only the DAEDONG genuine part for replace-

ment to maintain the performance and safety.

10.Replace the packing bearing and O-ring as new

part. Apply the grease properly for O-rings and oil

seals before assembly.

• Use the packing bond as three bond 1208D or

LOCTITE product.

• For using any packing bond, remove any re-

mained bond in the part before apply.

• Apply the bond in center of the flange between

bolt holes of the contact surface and apply the

inner surface for bolt hole portion.

• Perform the assembly within 10 minutes after

apply and inject oil after passing 30 minutes

above.

IMPORTANT

11.For assembling any snap ring for shaft or snap ring

for hole, assemble the head by the direction to be

forced, like above figure.

12.Insert the split portion of any spring pin by the direc-

tion to be forced, like above figure.

13.Replace any split pin as a new one.

3.1 ASSEMBLY AND DISASSEMBLY

Loading...

Loading...