25

Item Method Discard limit or criteria Action

Braking

mecha-

nism

Visually check the braking

surface to ensure no

abrasions or aws.

Do not lubricate the Friction

Plate.

The Friction Plate is a dry type brake.

Lubricating the Friction Plate may result in death

or severe injury due to insufficient braking.

• Should free of scars or gouged aws on the

braking surface of the Friction Disc, Friction

Plate, Ratchet Disc, and Hand Wheel

Assembly.

• The braking surface of the above mentioned

parts should not be excessively worn with

the tool marks erased and surface lustered.

Replace the scarred or

worn parts.

Check the crack of the

Friction Plate visually and

measure the abrasion using

calipers.

• The Friction Plate should be free of chips or

cracks.

Replace both Friction

Plates.

Measure the abrasion of

Bushing using a vernier

caliper.

• Should be uniform in thickness. Replace the Bushing.

Heat the Bushing with a

match ame to check that it is

impregnated with oil.

• Bushing should be sufciently impregnated

with oil (such that oil oozes off the surface

when heated).

Soak the Bushing in

turbine oil for a day and

wipe off excessive oil.

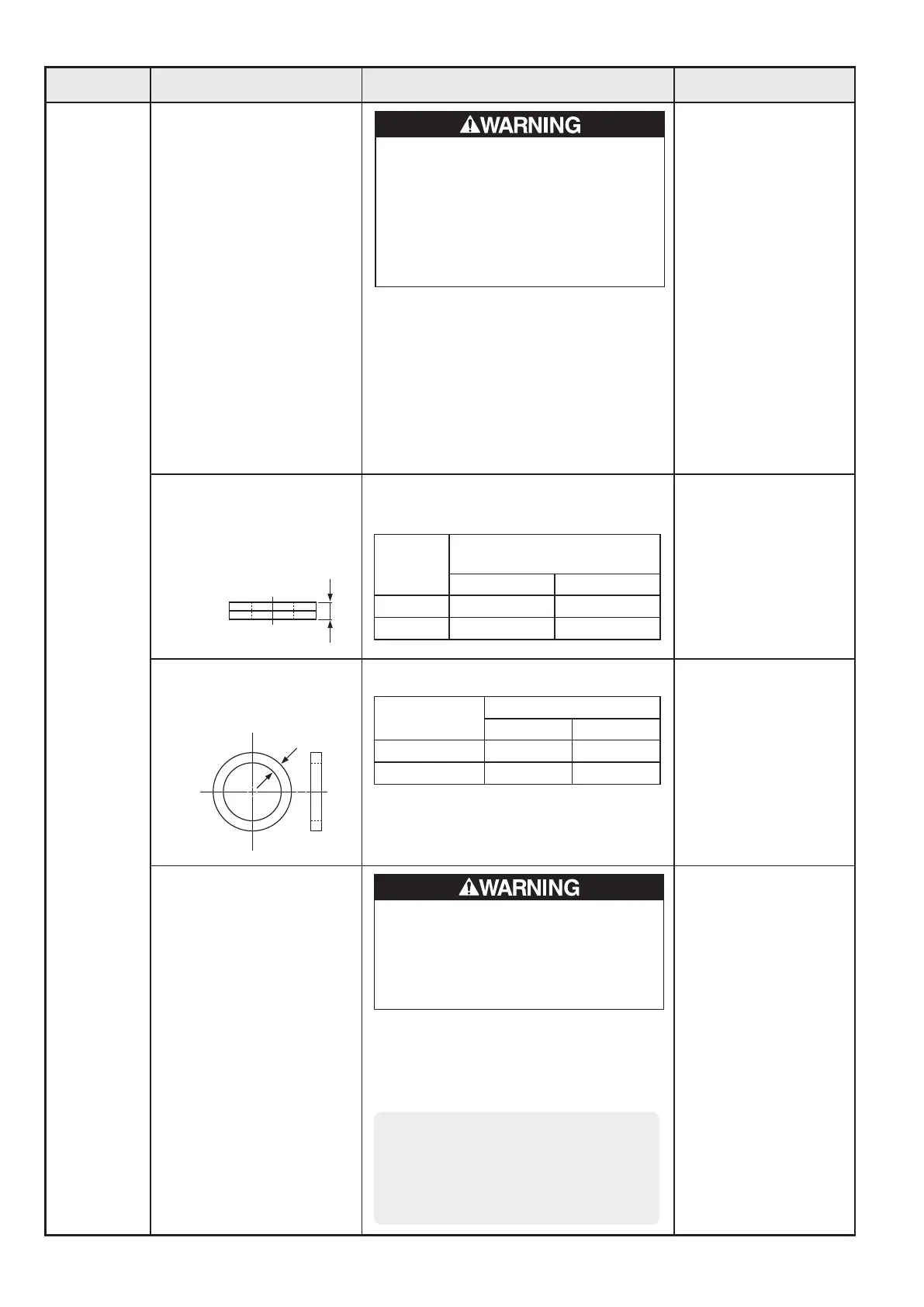

Two-ply

t

A

(Continued on the following page)

Rated load (t)

Thickness of two Friction Plates

Dimension t (mm)

Standard Limit

0.25 5.0 4.5

0.5

5.0 4.5

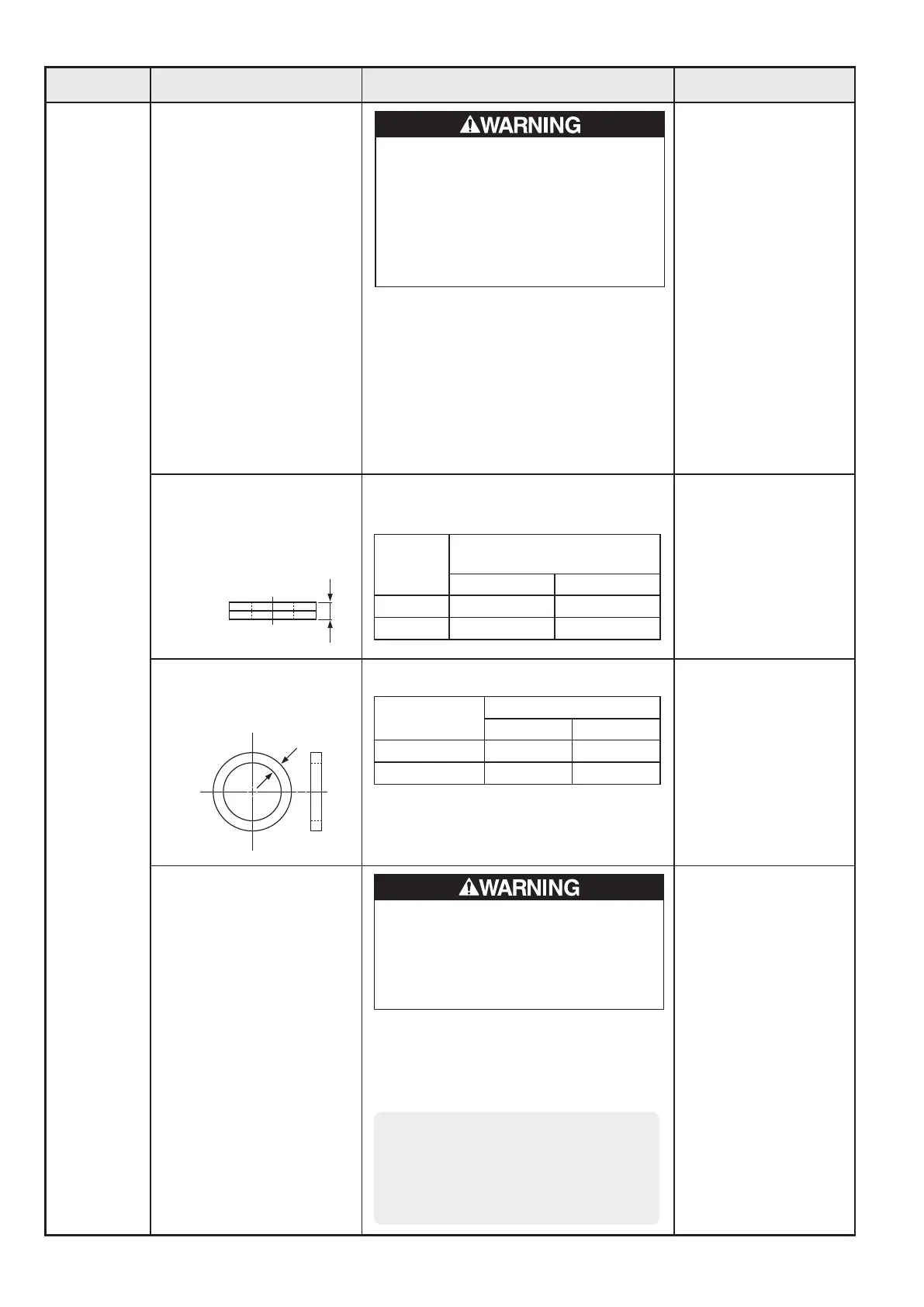

Rated load (t)

Dimension A (mm)

Standard Limit

0.25 1.4 1.2

0.5

2.0 1.8

For replacing or assembling Bushing, soak it in

turbine oil for a day, and wipe excessive oil from

its surface before reuse.

NOTE

Do not use any oil (grease, rust

preventive oil, etc.) in areas near

a fire or spark.

Failure to do so may result in ignition.

Loading...

Loading...