86

When performing the inspection, check the number of start and operating hours and utilize them for operation status

control and maintenance control.

Check the number of start and operating hours with the indicator of the VFD by the maintenance engineer in

accordance with the separate “VFD Manual” and P84 of this manual.

■

Guidelines and Precautions on Gear Oil Change Cycle

Change the gear oil in accordance with the rate of loading and the operating hours.

● Change the oil at every five years even if the operating hours do not reach at the following hours.

Operating hour for gear oil change

Rate of loading

Every 120 hrs Every 240 hrs Every 360 hrs

Light

A case where the capacity is rarely applied. Usually the hoist is

used with a light load.

○

Medium

A case where the capacity is applied considerably frequently.

Usually the hoist is used with a medium load.

○

Heavy

A case where the capacity is applied considerably frequently.

Usually the hoist is used with a heavy load.

○

Ultra

heavy

A case where the capacity is applied constantly.

○

Guidelines for Parts Replacement based on Indication of CH Meter

Chapter 2 Inspection

Guidelines for Parts Replacement based on Indication of CH Meter

2

CAUTION

• Use of wrong gear oil may result in the drop of the lifted load. Be sure to use the designated gear oil.

Mandatory

Code

Amount gear oil(ml)

Oil

EQ001IS, EQ003IS, EQ005IS 510 KITO genuine product

EQ010IS 840 KITO genuine product

Gear oil kind and amount for main unit

■

Guidelines for Checking Brake

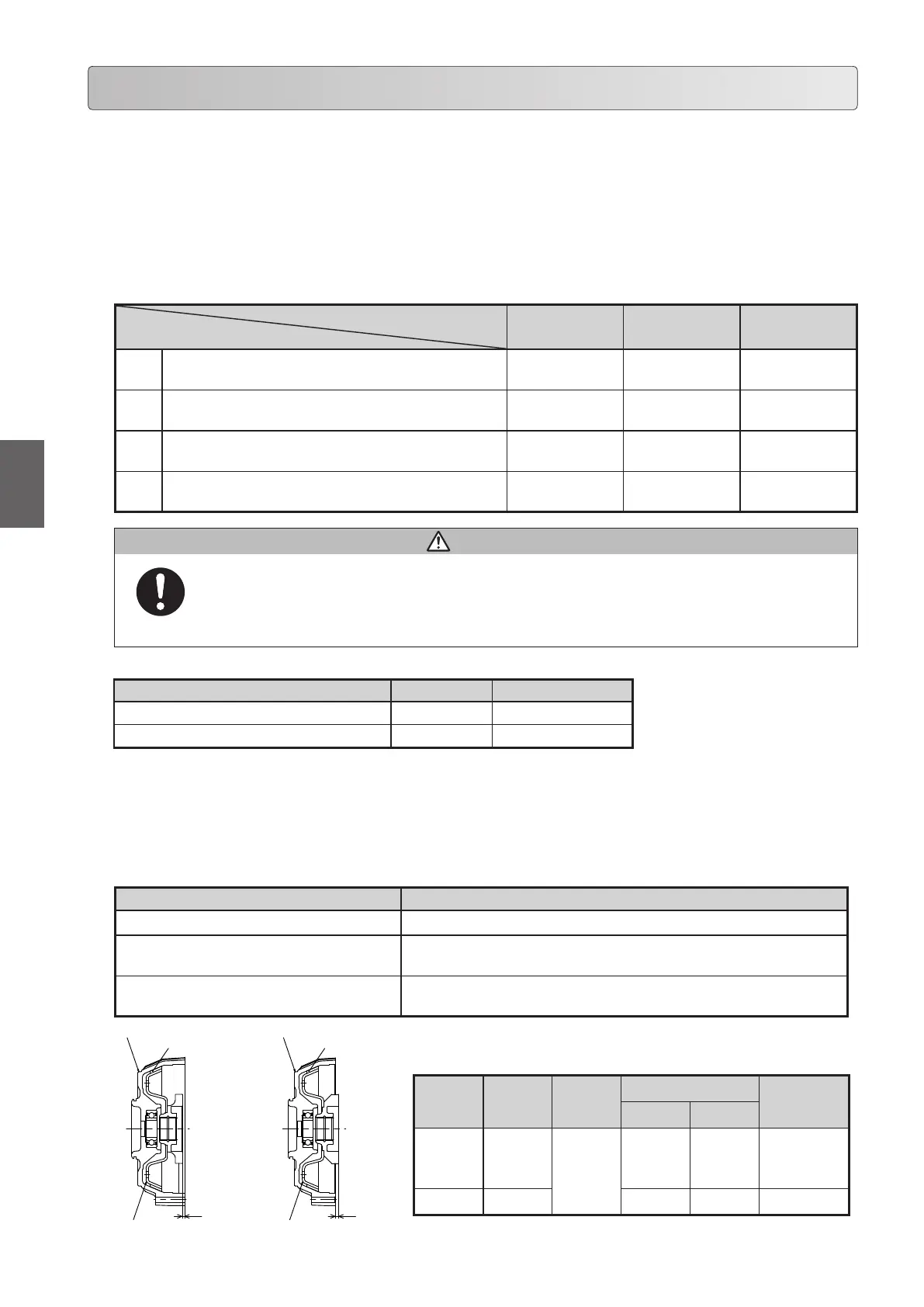

● When the number of start reaches 1 million times, check the dimension of B and execute the counteraction in the

table below depending on the condition.

● When the number of start reaches 2 million times, replace the brake drum, motor cover, brake spring and pull rotor

spring no matter what condition the B dimension is.

Condition of B dimension Action

When it reaches the critical limit

Replace the brake drum, motor cover, brake spring and pull rotor spring.

When it reaches near end of the critical limit rather than the

intermediate point between standard and critical limit.

From that time on, check the B condition every hundred thousand times of use till it reaches to

the critical limit.

When it reaches near end of the standard rather than the

intermediate point between standard and critical limit.

Check the B condition every two hundred thousand times of use.

Abrasion of Brake pad when using Brake

(It should not below the limit.)

Code Capaciy Speed

B dimension (mm)

Criteria

Standard Limit

EQ001IS

EQ003IS

EQ004IS

EQ005IS

125kg,

250kg,

490kg,

500kg

Dual

3 3.5 Not to exceed

EQ010IS 1t 4 3.5 Not to fall below

B

Brake Pad

Moter Cover

B

Brake Pad

Moter Cover

<125kg, 250kg, 490kg, 500kg> <1t>

Loading...

Loading...