154

Appendix

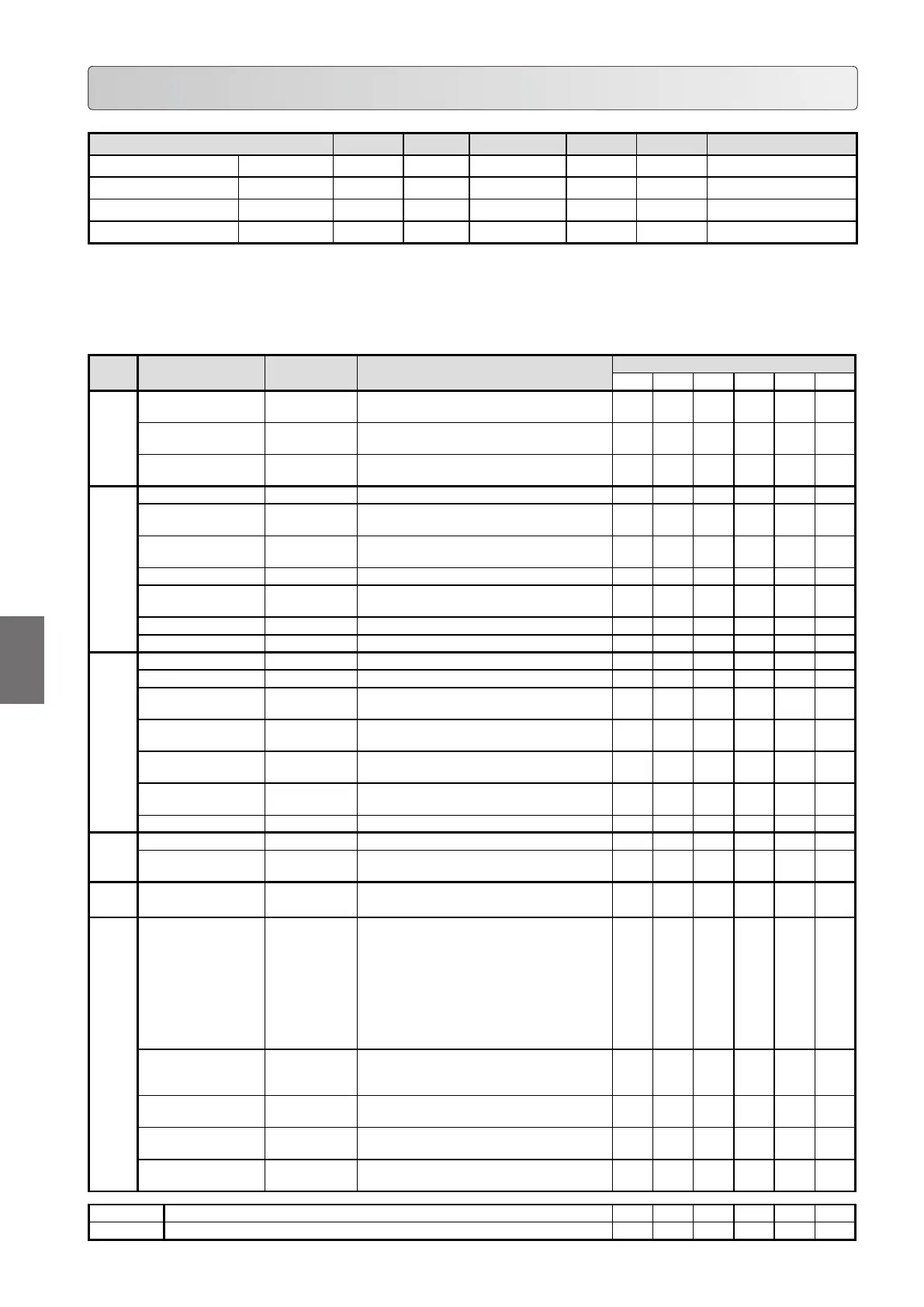

Check Sheet for ER2 Series Electric Chain Hoist Daily Inspection

■

Electric Chain Hoist ER2 Daily Inspection

■

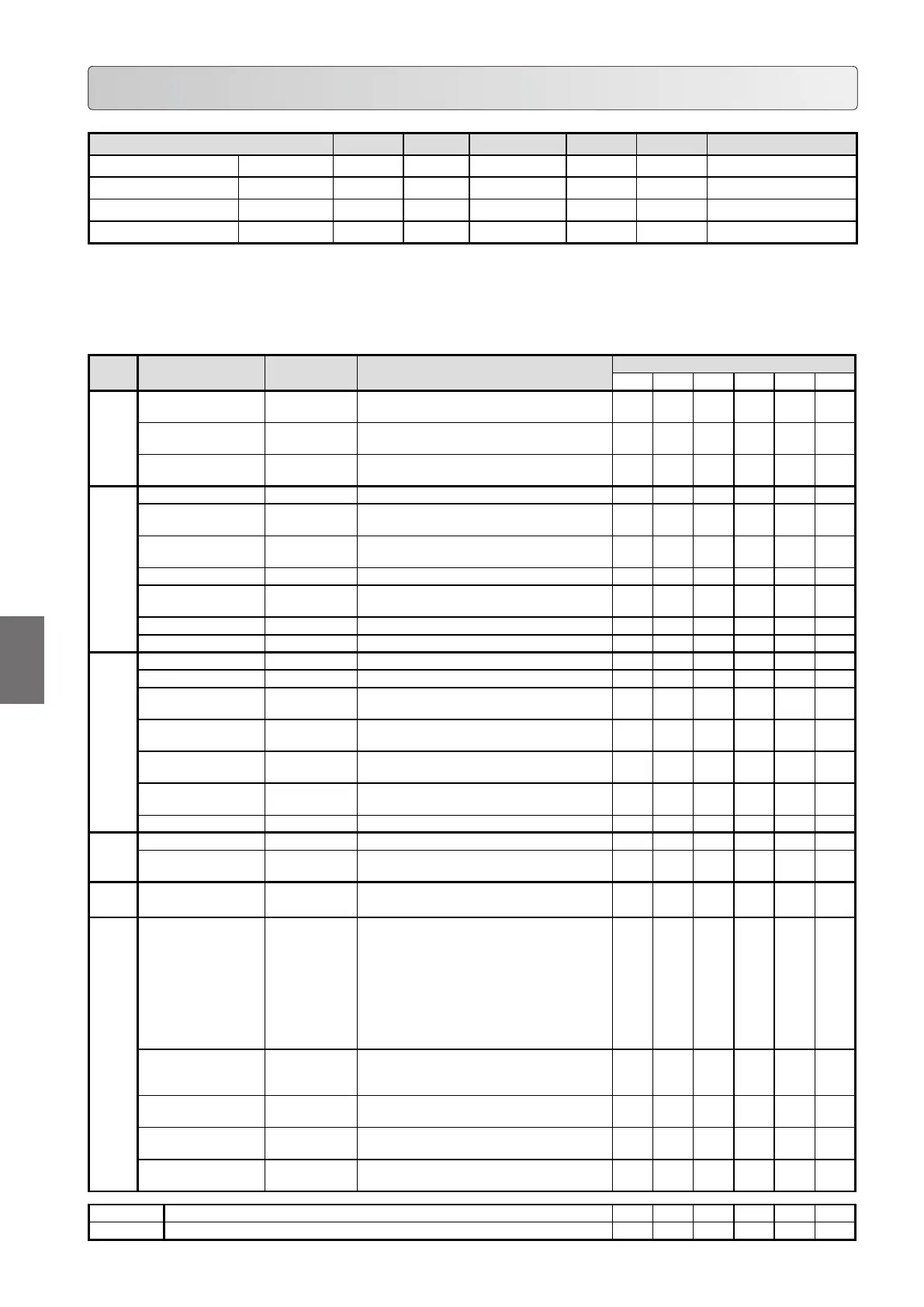

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Code Capacity Lot No. Your CTRL No.

Installation date

Location

Inspection Certification valid thru

Electric Chain Hoist ER2

Motorized Trolley MR2

Geared Trolley

TS2 (TSG)

Plain Trolley

TS2 (TSP)

A

Check Sheet for ER2 Series Electric Chain Hoist Daily inspection

Category

Check item Check method Criteria

Inspection date/result

/ / / / / /

Appearance

Indication of nameplates

and labels

Visual inspection To have no peeled off. To be legible clearly.

Deformation and damage

of each part of body size

Visual inspection To have no apparent deformation or corrosion

Bolts, nut, split pins Visual inspection

To have no loosened bolts, nuts, and split pins that

can be seen from exterior. To have no come-off.

Load Chain

Elongation of pitch Visual inspection To have no apparent elongation

Abrasion of wire

diameter

Visual inspection To have no apparent abrasion

Deformation,aw,

entanglement

Visual inspection

Tohavenoapparentdeformation,harmfulawand

entanglement

Rust, corrosion Visual inspection To have no apparent rust and corrosion

Twist Visual inspection

To have no twisting due to capsized Bottom Hook of

double type

Oiling Visual inspection To be oiled adequately

Check of mark Visual inspection To have no error in indication and marked pitch

Top Hook, Bottom Hook

Stretched opening Visual inspection To have no stretched opening

Abrasion Visual inspection To have no apparent abrasion

Deformation,aw,

corrosion

Visual inspection

Tohavenoapparentdeformation,harmfulawand

corrosion

Hook Latch motion

Visual inspection/

inspection by operation

To open/close smoothly

Hook motion (swivel)

Visual inspection/

inspection by operation

To have no apparent gap between Hook and Bottom

Yoke

Idle Sheave motion

Visual inspection/

inspection by operation

Load Chain to move smoothly

Bottom Yoke Visual inspection To have no loosened bolt and nut

Body size

peripheral

part

Chain spring Visual inspection To have no apparent permanent set

Cushion rubber Visual inspection

• To have no apparent permanent set

• To have no crack and peel off of rubber and steel plate

Push

Button

Switch

Switch body size Visual inspection

• To have no deformation, damage and loosened screw

• Indication to be legible clearly

Function/performance

Operational check

Press the push

buttons to check

the operation

• Load Chain to be wound smoothly

• Electric Chain Hoist operates in the same direction as

that of the push button operation

• Motor to stop immediately when stopping the operation

• All operations to stop when Emergency Stop is pressed

• Electric Chain Hoist not to operate when pressing the

push button while Emergency Stop is pressed

• Electric Chain Hoist to operate normally when canceling

Emergency Stop

Brake

Lifting/lowering

operation with no

load

Brake to operate securely and Bottom Hook to stop

immediately (Guideline: Travel of the load chain is

within 2 to 3 links.)

Friction Clutch with

Mechanical Brake

Lifting/lowering

operation with no load

To sound clicking noise of pawl when lifting

Limit switch

Lifting/lowering

operation with no load

Motor to stop automatically when operating the

electric chain hoist to upper/lower limit

Strange noise

Lifting/lowering

operation with no load

To have no strange sound or vibration

Executed by Inspector

Checked by Maintenance Engineer

Loading...

Loading...