88

Periodic Inspection (continued)

Chapter 2 Inspection

■

Manual Trolley (TSG/TSP) Periodic Inspection

■

Body size Components

Item Check method Criteria When failed

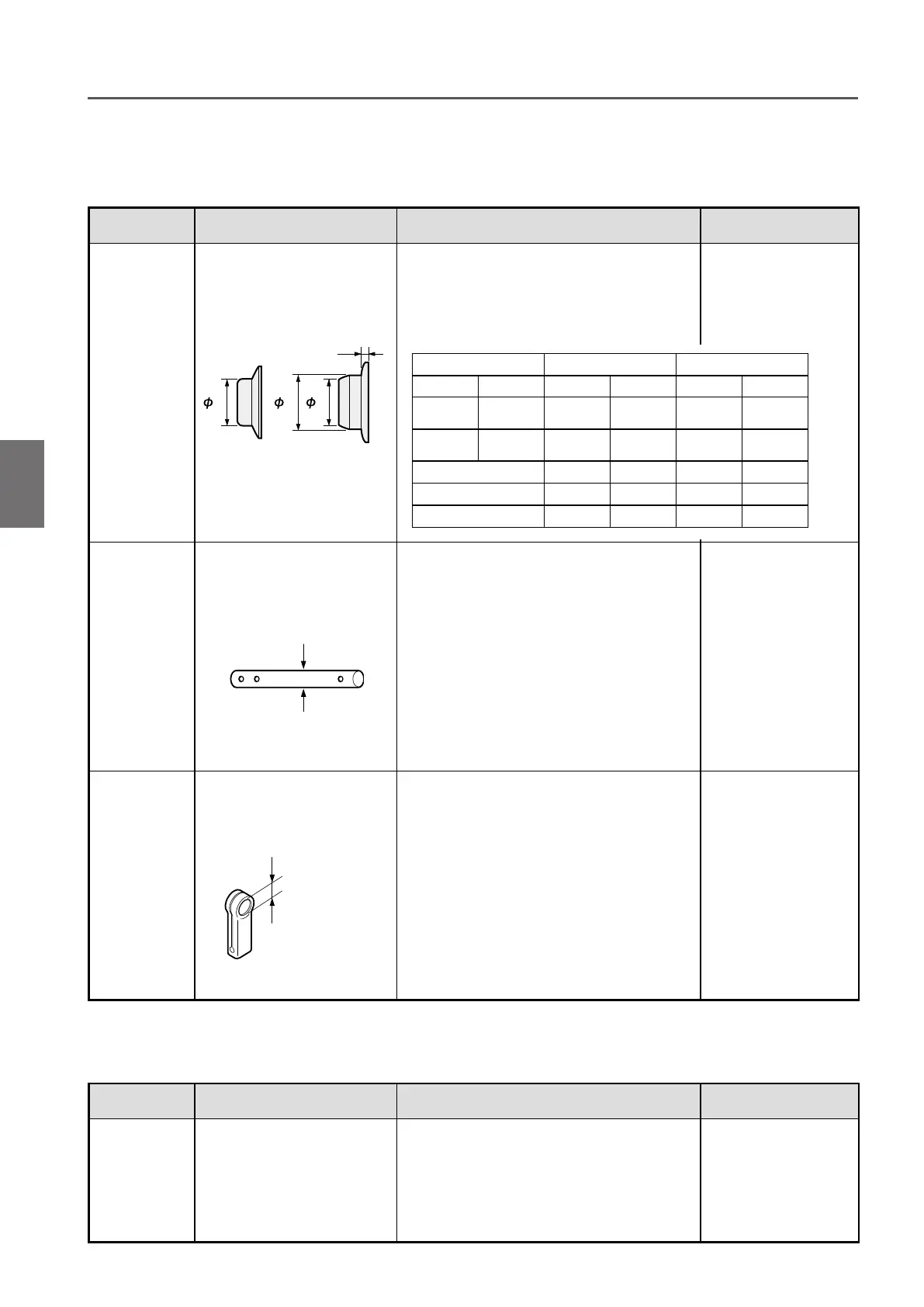

Wheel • Check visually.

• Measure dimensions D and

t with vernier caliper.

t

d

0.5~3t0.5~3t 5t5t

D D

• Measure the outer diameter

with vernier caliper.

• To have no considerable deformation

and damage

• Abrasion Limit of Wheel

(Do not fall under the limit.)

Capacity D (mm)

Flange thickness t (mm)

TSP TSG Standard

Limit

Standard

Limit

125, 250,

500kg

– 60 58.5 3.2 2.5

1t

125, 250,

500kg, 1t

71 68.5 4 3.3

1.5t, 2t 85 83.5 4.5 3.8

2.5t, 3t 100 98.5 5 4.3

5t 118 112 9.6 6.7

Replace the Wheel.

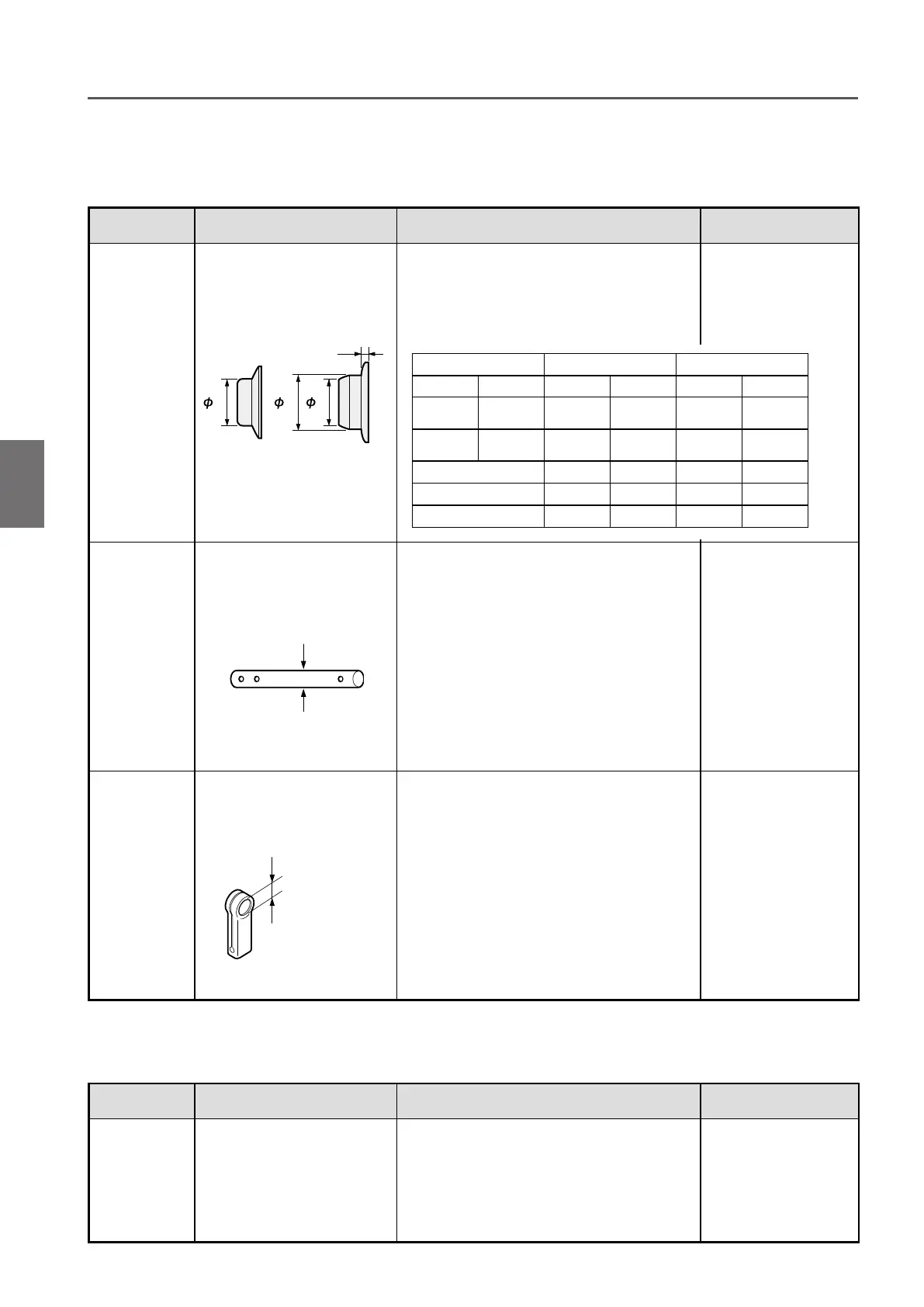

Lifting Shaft • Check visually.

• Measure the shaft diameter

with vernier caliper.

Shaft diameter

• To have no considerable deformation and

abrasion

• The shaft with obvious deformation reaches at

the service limit.

• Abrasion limit of the shaft and the hole is 5 %

of its diameter respectively.

Replace the Lifting

Shaft.

Suspender • Check visually.

• Measure the diameter of the

hole with vernier caliper.

Hole diameter

• The Suspender must be combined securely

with the top pin and the Yoke bolt.

• Abrasion limit of the hole is 5 % of its diameter.

Replace the

Suspender.

Item Check method Criteria When failed

Rail Surface • Check visually. • To have no attachment of paint, oil and foreign

matter.

• To have no dust and powder due to abrasion

Clean the Travel Rail.

■

Travel Rail

Manual Trolley (TSG/TSP) Periodic Inspection Periodic Inspection

2

Loading...

Loading...