158

Appendix

Check Sheet for

ER2 Series

Electric Chain Hoist Periodic Inspection

■

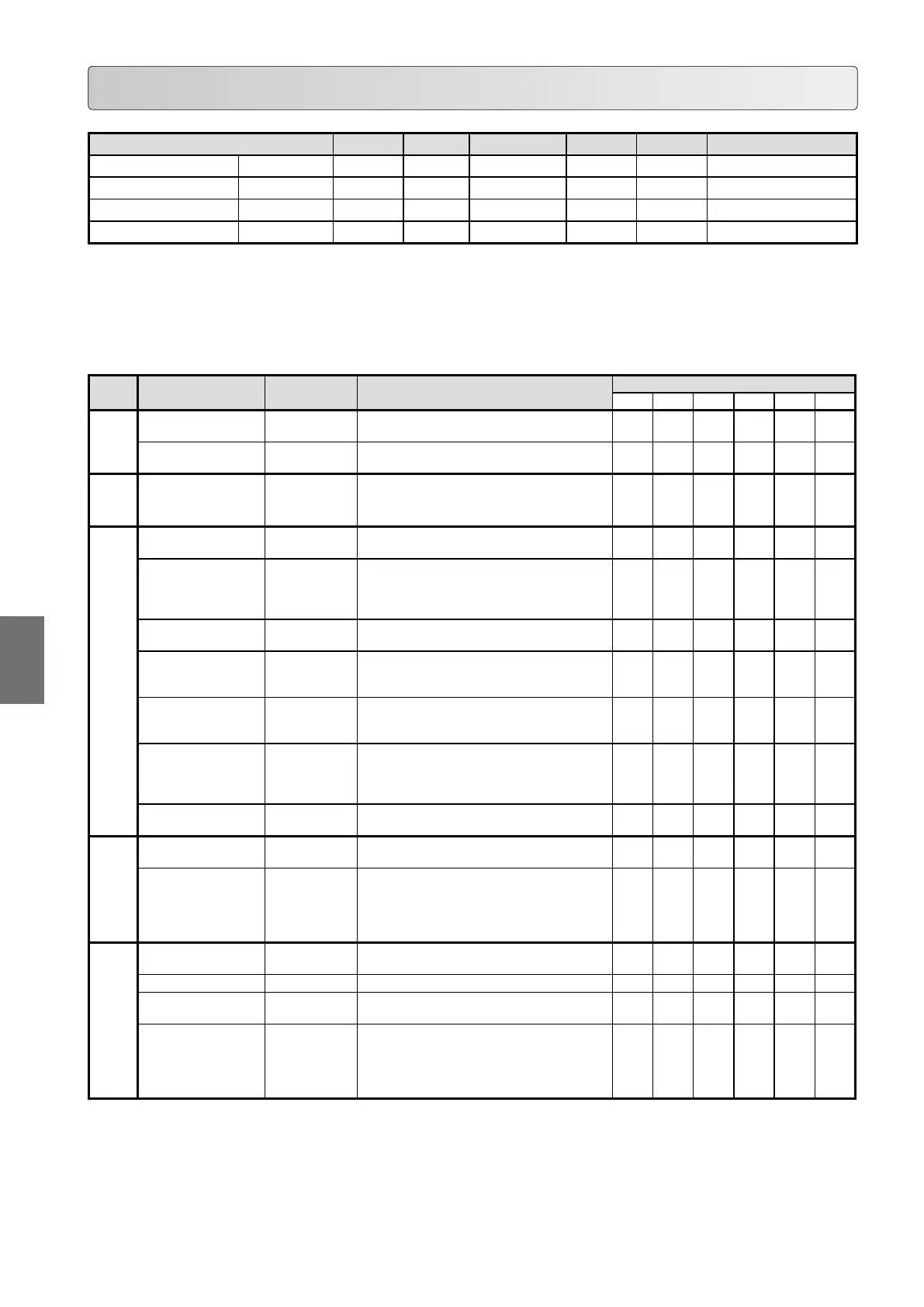

Electric Chain Hoist ER2 Periodic Inspection (1/2)

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Category

Check item Check method Criteria

Inspection date/result

/ / / / / /

Preceding

inspection

Daily inspection

Check the

execution

When performing periodic inspection, also perform

the daily inspection.

Frequent inspection

Check the

execution

When performing periodic inspection, also perform

the frequent inspection.

Top Hook,

Bottom

Hook

Number of start Check CH Meter

Number of start not to exceed the guidelines for

replacement

Body size peripheral part

Chain guide A Visual inspection

• To have no apparent abrasion and damage

• TohavenoawduetohittingbyLoadChain

Chain spring

Visual inspection/

inspection by

measurement

• To have no apparent permanent setting

(deformation)

• Length of the chain spring to be longer than the

criteria

Stopper Visual inspection

Stopper must be mounted securely at the third link

from the load chain end at no load side

Limit lever

Visual inspection/

inspection by

operation

• To have no deformation, damage and abrasion

• To move smoothly

• To be clean

Chain pin

Visual inspection/

inspection by

measurement

• Tohavenoapparentdeformationandaw

• Not to lower the criteria

Connection Yoke

Visual inspection/

inspection by

measurement

• To have no apparent deformation, abrasion and

damage

• The difference between the hole diameter in

vertical and lateral to be within 0.5 mm

Shaft retainer clip Visual inspection

• To have no deformation, damage and abrasion

• To be mounted securely without looseness

Oil

Oil leakage Visual inspection

To have no oil leakage at packing, oil seal and oil

plug

Oil amount and stain Visual inspection

• Oilislledenoughclosetotheoilcheckhole.

• Gear oil has viscosity but not stained.

• Check the operating hours with CH Meter.

Operating hours not to exceed the guidelines for

oil change.

Electromagnetic brake

Appearance Visual inspection

• To have no loosened bolts and screws

• Tohavenoawanddamage

Gap Measurement The gap not to exceed the limit value

Hub and joint Visual inspection

• To have no deformation and abrasion

• Hub spring not to come off

Number of start

Check the CH

Meter

Check the gap at the number of start arrives at one

million times. Check the gap regularly after that

and replace the electromagnetic brake when the

gap arrives at the limit gap or the number of start

arrives at two million times.

A

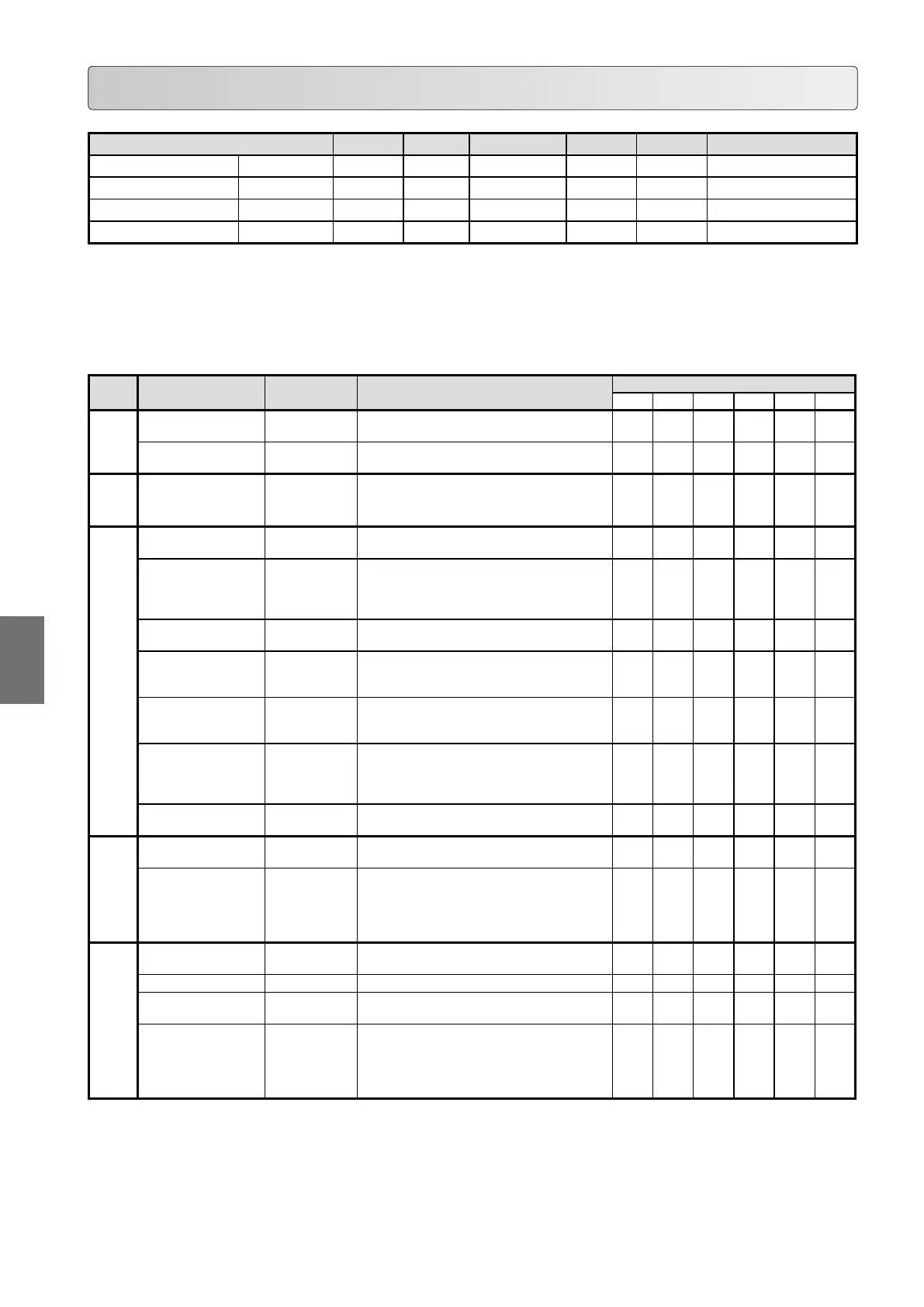

Check Sheet for ER2 Series Electric Chain Hoist Periodic Inspection

Code Capacity Lot No. Your CTRL No.

Installation date

Location

Inspection Certification valid thru

Electric Chain Hoist ER2

Motorized Trolley MR2

Geared Trolley

TS2 (TSG)

Plain Trolley

TS2 (TSP)

Loading...

Loading...