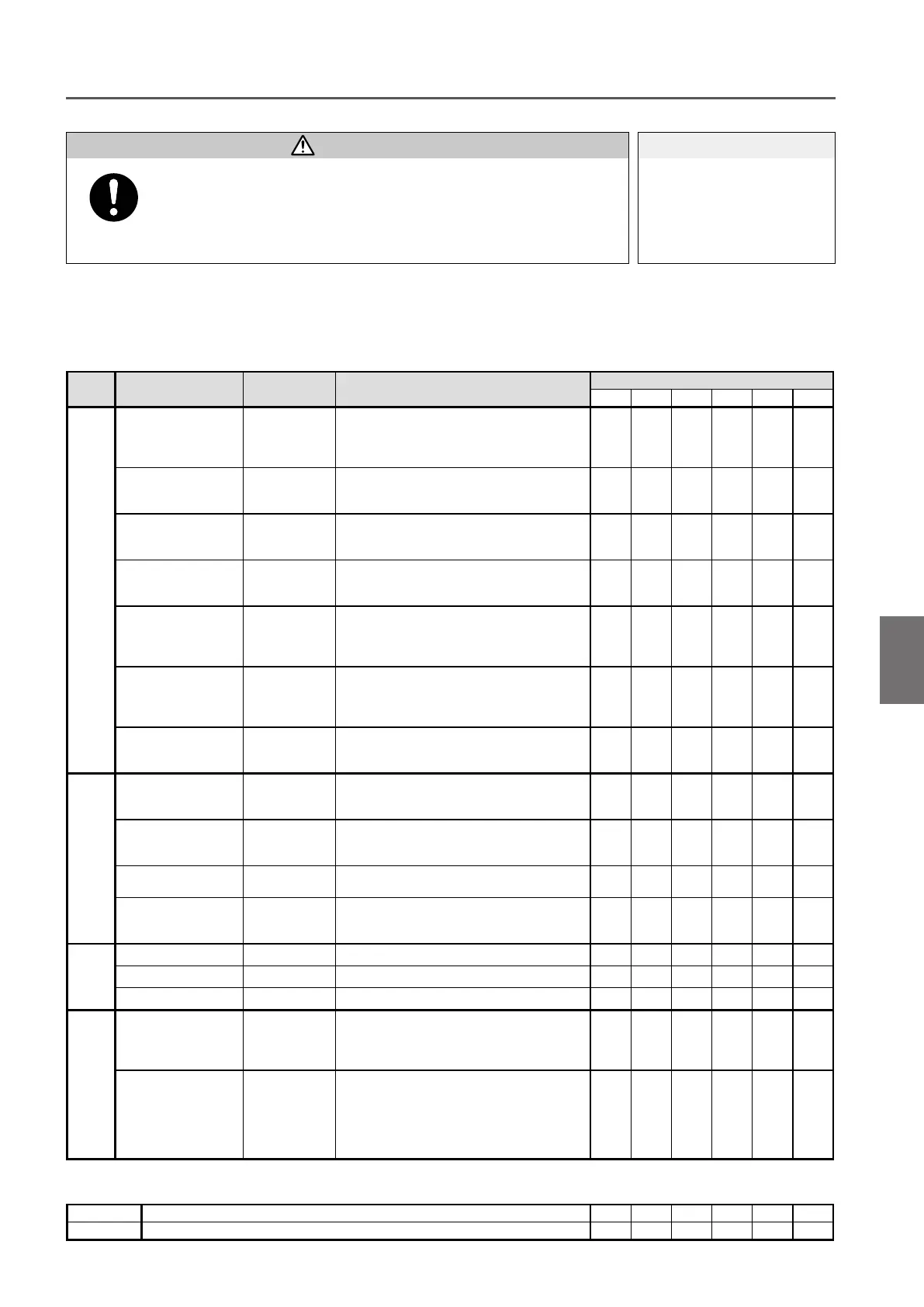

159

Category

Check item Check method Criteria

Inspection date/result

/ / / / / /

Driving unit

Bearing

Visual inspection,

Check CH Meter

• Tohavenoapparentabrasion,awanddamage

• To move smoothly

• Operating hours not to exceed the guidelines for

replacement of bearing

Load gear, Gear B,

Pinion

Visual inspection,

Check CH Meter

• To have no apparent abrasion, deformation and damage

• Operating hours not to exceed the guidelines for

replacement of bearing

Friction clutch

Visual inspection,

Check CH Meter

• Tohavenoapparentabrasion,deformationandaw

• Operating hours not to exceed the guidelines for

replacement of gears

Friction Clutch with

Mechanical Brake

Visual inspection,

Check CH Meter

• Tohavenoapparentabrasion,deformationandaw

• Operating hours not to exceed the guidelines for

replacement of gears

Load sheave

Visual inspection/

inspection by

measurement

• To have no apparent abrasion, deformation and damage

• Tohavenoawonsheavepocketduetodefective

engagement

• The thickness of sheave pocket must not lower the criteria.

Idle sheave

Visual inspection/

inspection by

measurement

• To have no apparent abrasion, deformation and damage

• Tohavenoawonsheavepocketduetodefective

engagement

•

The thickness of sheave pocket must not lower the criteria.

V ring

Visual inspection,

Check CH Meter

• To have no deformation and crack

• Apply grease MOLITHERM No.2 on the V ring at

brake cover side at 200 hours of operating hours

Electrical parts

Electrical parts Visual inspection

• To have no damaged or burnt part

• To be mounted securely

• Number of start no to exceed the guidelines for replacement

Wiring Visual inspection

• Wiringtobexedtoelectricalpartssecurely

• Connector to be inserted securely

• To have no damaged or burnt part

Intrusion or attachment

of foreign matter

Visual inspection

• To have no water drop or foreign matter such as

dust inside

VFD

Check the CH

Meter (check of

service life)

• Electrolytic capacitors 3000 hours (depending on

the operating conditions)

• Refer to “VFD Manual” for other items.

Electric

characteristics

Source voltage Measurement To be supplied power within rated voltage ± 10 %

Insulation resistance Measurement Insulationresistancetobehigherthan5MΩ

Grounding resistance Measurement

Tobegroundedwithgroundingresistance100Ωorless

Function/performance

Operational check

Lifting/lowering

operation with a

capacity

Perform inspection of the items on function/

performance of daily inspection and frequent

inspection with no load, and then perform the

inspection of the same items with a capacity.

Brake

Lifting/lowering

operation with a

capacity

Visual inspection/

inspection by

measurement

Stopping distance of lifting/lowering to be within

1 % of the lifting distance

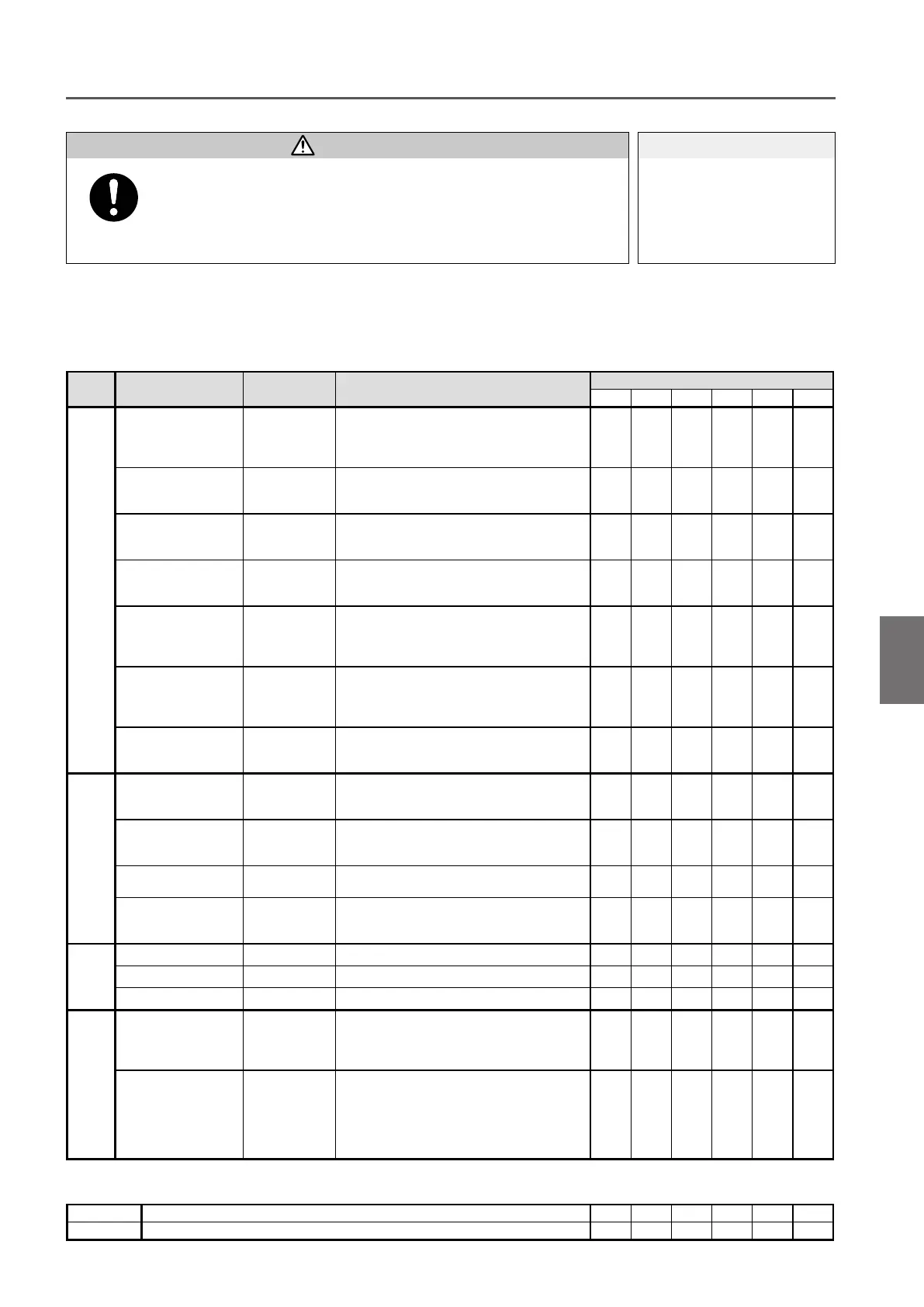

■

Electric Chain Hoist ER2 Periodic Inspection (2/2)

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

(to be continued)

A

Check Sheet for

ER2 Series

Electric Chain Hoist Periodic Inspection

• When any abnormality is observed during inspection, stop the use of

electric chain hoist, indicate “FAILURE”, and contact the maintenance

engineer or KITO for repair.

Use of the product with abnormality may result in death or serious injury.

Mandatory

Decide the check items

appropriate to the

environment and operating

conditions of the customer.

NOTE

Executed by Inspector

Checked by Maintenance Engineer

DANGER

Loading...

Loading...