84

Periodic Inspection (continued)

Chapter 2 Inspection

Item Check method Criteria When failed

Wheel • Check visually.

• Measure dimensions D and

d with vernier caliper.

d

D

Wheel for I · H beam (0.5 to 5 t)Wheel for I · H beam (0.5 to 5 t)

Measure the outer diameter

with vernier caliper.

• To have no considerable deformation

and damage

• Abrasion Limit of Wheel

(Do not fall under the limit.)

Capacity (t) Beam type

D (mm) d (mm)

Standard Limit Standard Limit

125, 250, 500kg I · H 95 91 91.5 87.5

1 I · H 95 91 91.5 87.5

1.5, 2 I · H 110 105 106 101

2.5, 3 I · H 125 118 121 114

5 I · H 140 132 135 127

Replace the Wheel.

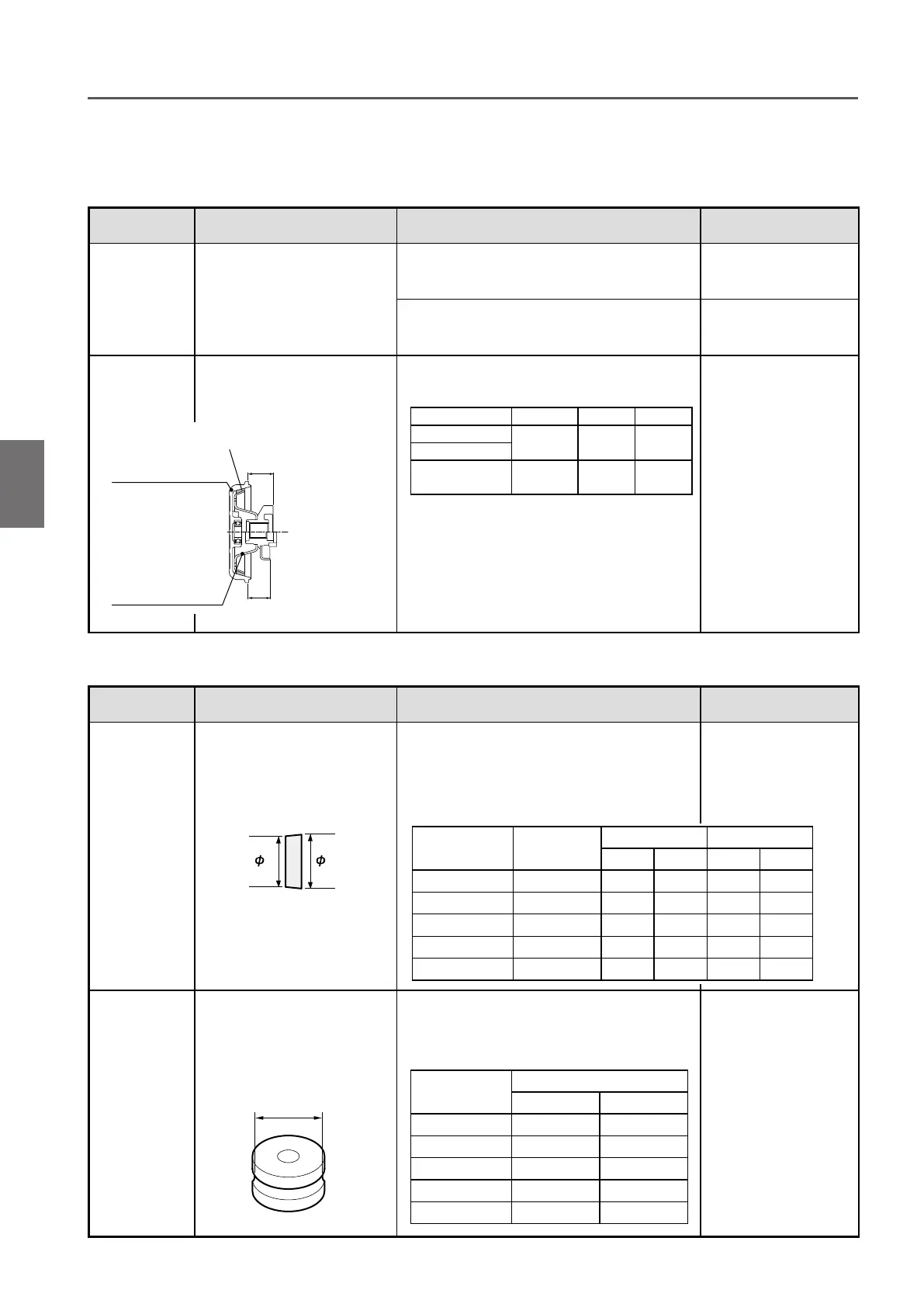

Side Roller • Check visually.

• Measure outer diameter of

the worn part with vernier

caliper.

Outer diameter

•

To have no considerable deformation and damage

• Abrasion Limit of Side Roller

(Do not fall under the limit.)

Capacity (t)

Outer diameter (mm)

Standard Limit

125, 250, 500kg 38 37

1 38 37

1.5, 2 43 42

2.5, 3 43 42

5 55 54

Replace the Side

Roller.

■

Motorized Trolley (MR2) Periodic Inspection

■

Brake

Item Check method Criteria When failed

Appearance • Disassemble the Brake and

check it visually.

• Tohavenodeformation,awanddamageon

the Brake Drum and the Motor Cover.

Replace the Part.

• To have no deformation and damage on the

Brake Spring.

Replace the Brake

Spring.

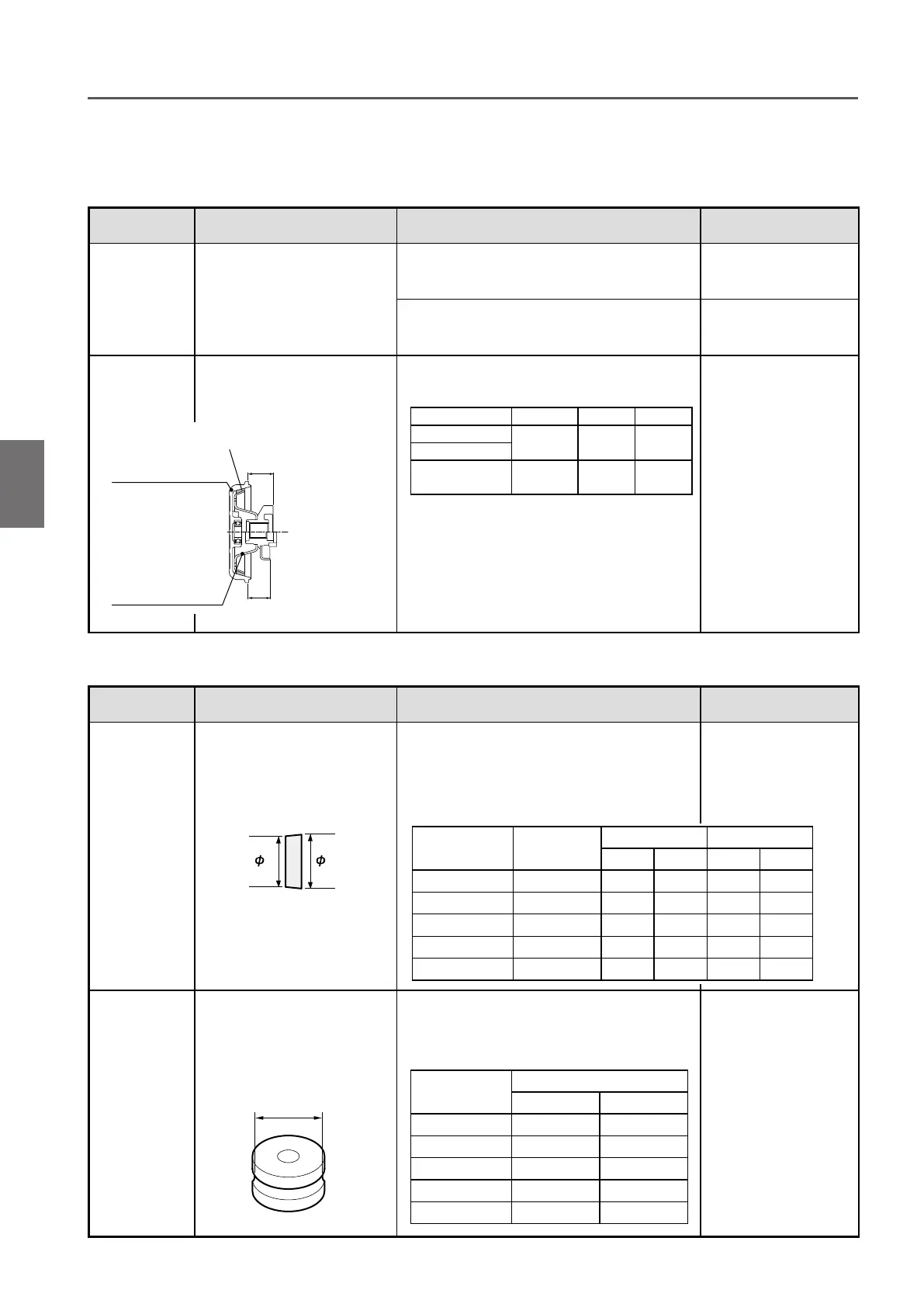

Abrasion of

Brake Pad

• Disassemble the Brake and

measure the abrasion.

Trolley Brake Service Limit

(Do not fall under the limit.)

Speed Dimension Standard Limit

Single Speed

B

32.5 31.0

Dual Speed (VFD)

Dual Speed

(500V Class)

B' 36.8 36.3

Replace the Motor

Cover.

Brake Pad

Motor Cover

Brake Drum

B’

B

■

Body size Components

Motorized Trolley (MR2) Periodic Inspection Periodic Inspection

2

Loading...

Loading...