161

■

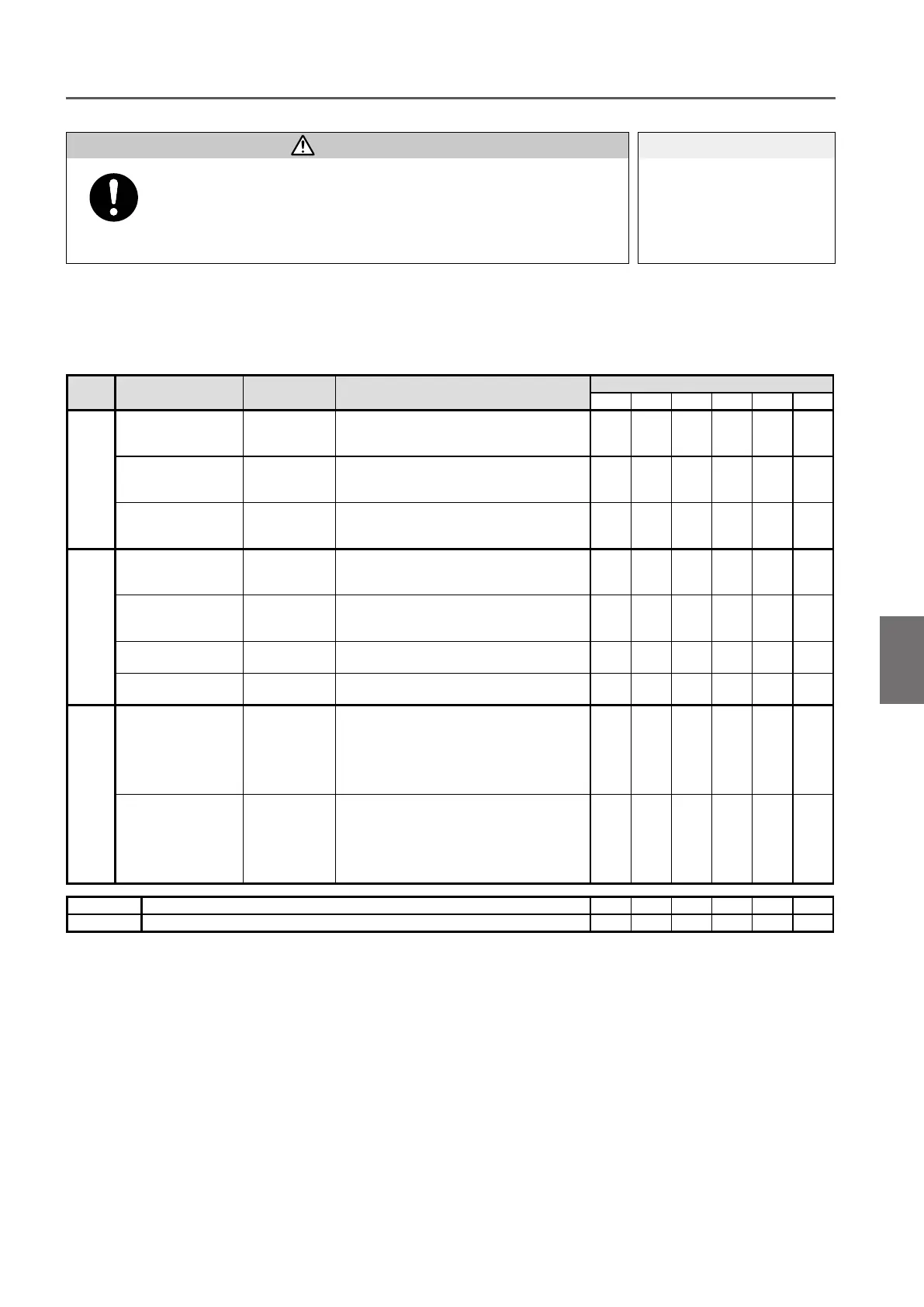

Manual Trolley TS2 (TSG/TSP) Periodic Inspection

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Category

Check item Check method Criteria

Inspection date/result

/ / / / / /

Body size component

Wheel

Visual inspection/

inspection by

measurement

• To have no apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Lifting shaft

Visual inspection/

inspection by

measurement

• To have no apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Suspender

Visual inspection/

inspection by

measurement

• To have no apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Travel rail

Rail surface Visual inspection

• To have no attachment of paint, oil and foreign

matter

• To have no dust and powder due to abrasion

Deformation, abrasion

Visual inspection/

inspection by

measurement

• Tohavenodeformationofbeamangesuchas

twist and shear drop

• To have no exceeding abrasion of rail surface

Railxingbolt Visual inspection

To be mounted securely without looseness and

come-off

Stopper Visual inspection

To be mounted securely without looseness and

come-off at the rail end

Function/performance

Operational check

Traveling

operation with a

capacity

Visual inspection/

inspection by

measurement

Perform inspection of the items on function/

performance of daily inspection with no load, and

then perform the inspection of the same items with

a capacity.

Strange noise

Traveling

operation with a

capacity

Visual inspection/

inspection by

measurement

Perform inspection of the items on function/

performance of daily inspection with no load, and

then perform the inspection of the same items with

a capacity.

• When any abnormality is observed during inspection, stop the use of

electric chain hoist, indicate “FAILURE”, and contact the maintenance

engineer or KITO for repair.

Use of the product with abnormality may result in death or serious injury.

Mandatory

Decide the check items

appropriate to the

environment and operating

conditions of the customer.

NOTE

Executed by Inspector

Checked by Maintenance Engineer

A

Check Sheet for

ER2 Series

Electric Chain Hoist Periodic Inspection

DANGER

Loading...

Loading...