23

Item Check method Criteria When failed

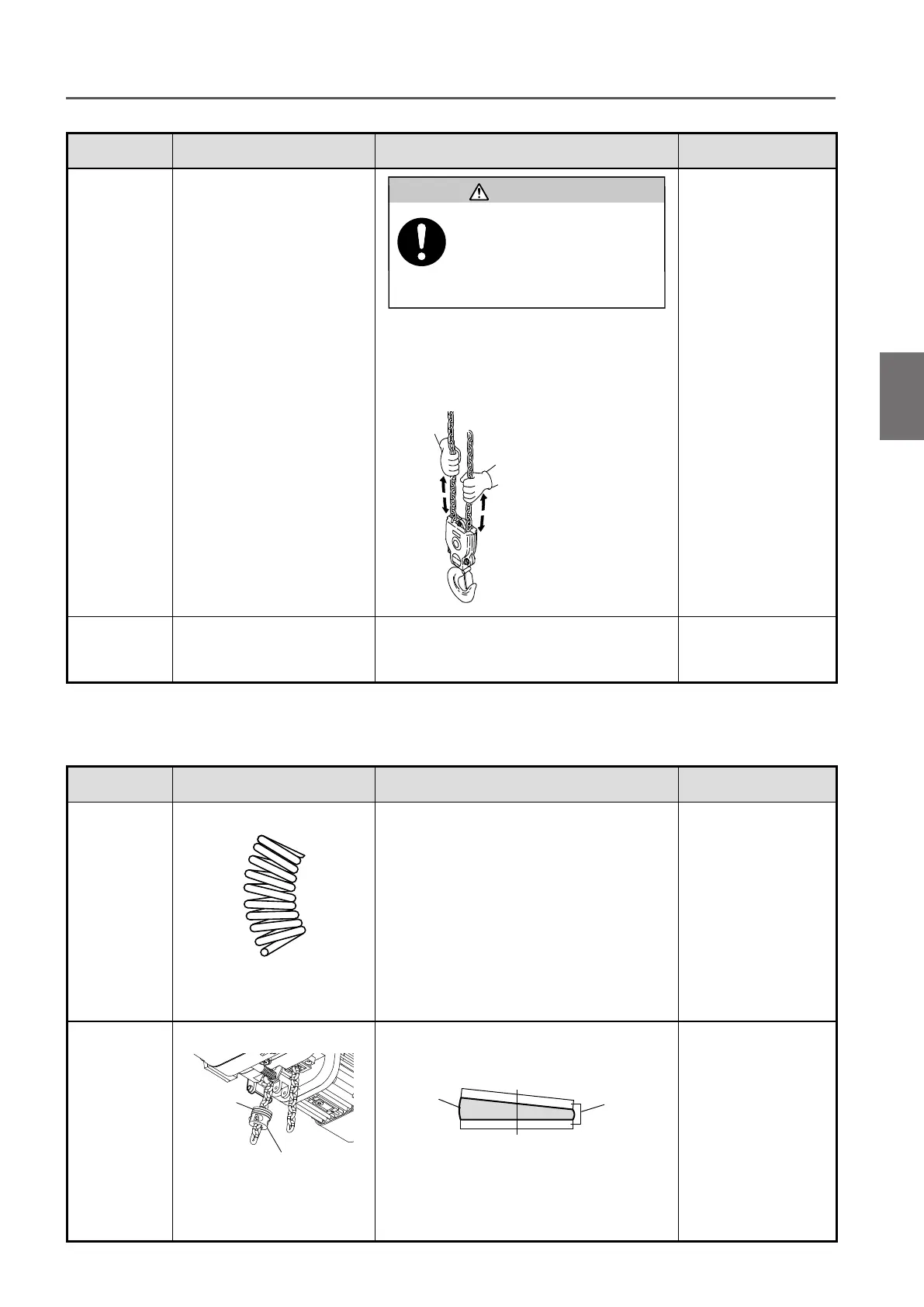

Movement

of the Idle

Sheave

• Check the Idle Sheave by

moving

• When checking, wear gloves

and be careful for your finger

not to be caught.

Otherwise it may result in injury.

Mandatory

CAUTION

• The Idle Sheave rotates smoothly.

* The Idle Sheave does not rotate smoothly

when bearing is damaged or sheave shaft is

deformed.

• The Load Chain moves smoothly.

Move the Load Chain

by hand.

Replace the bearing of

the Idle Sheave.

Bottom Yoke • Check visually. • No loosened bolt or nut

Attach the Bottom Hook to

the Load Chain securely.

■

Peripheral parts of the body size

Item Check method Criteria When failed

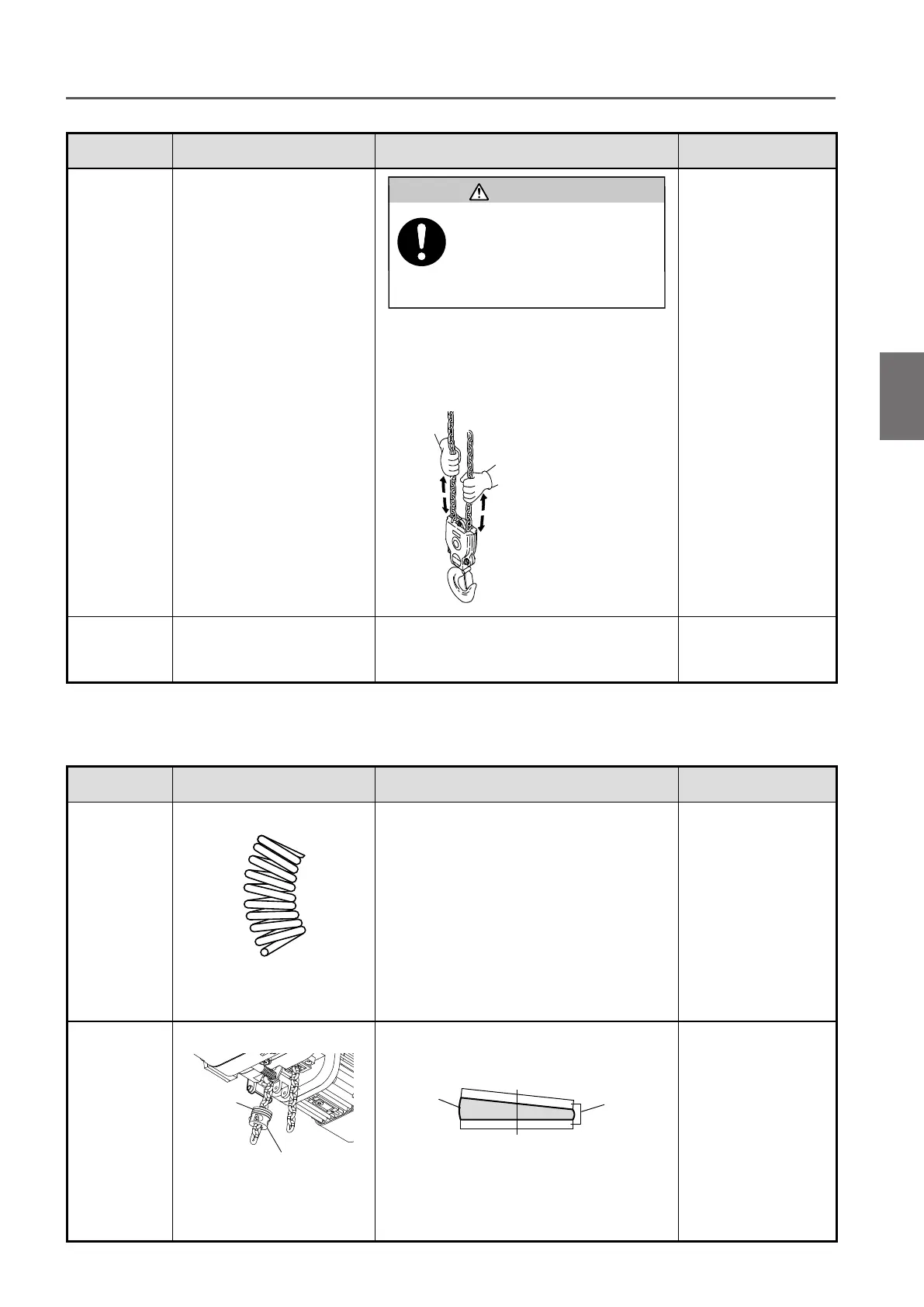

Chain Spring • Check visually • No apparent shrinkage or compression Carry out the

inspection item of

Chain Spring (P77) of

Periodic inspection.

Cushion

Rubber

• Check visually

Stopper

Cushion

Rubber

• No apparent shrinkage or compression

• No peel off, crack of deformation of rubber

Rubber

Steel plate

Replace the Cushion

Rubber.

(to be continued)

How to Use Daily Inspection of Electric Chain Hoist (Hook Suspended Type)

1

Loading...

Loading...