54

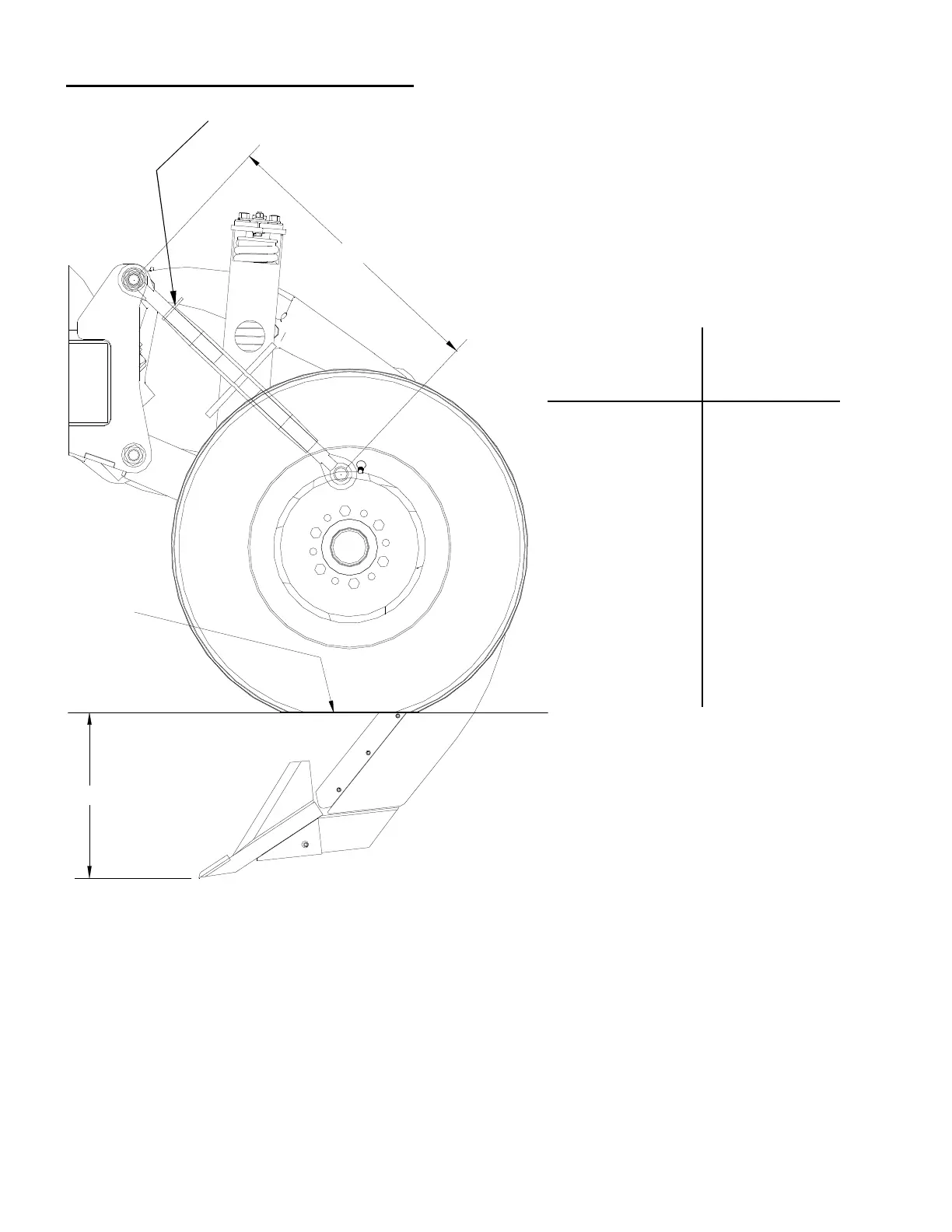

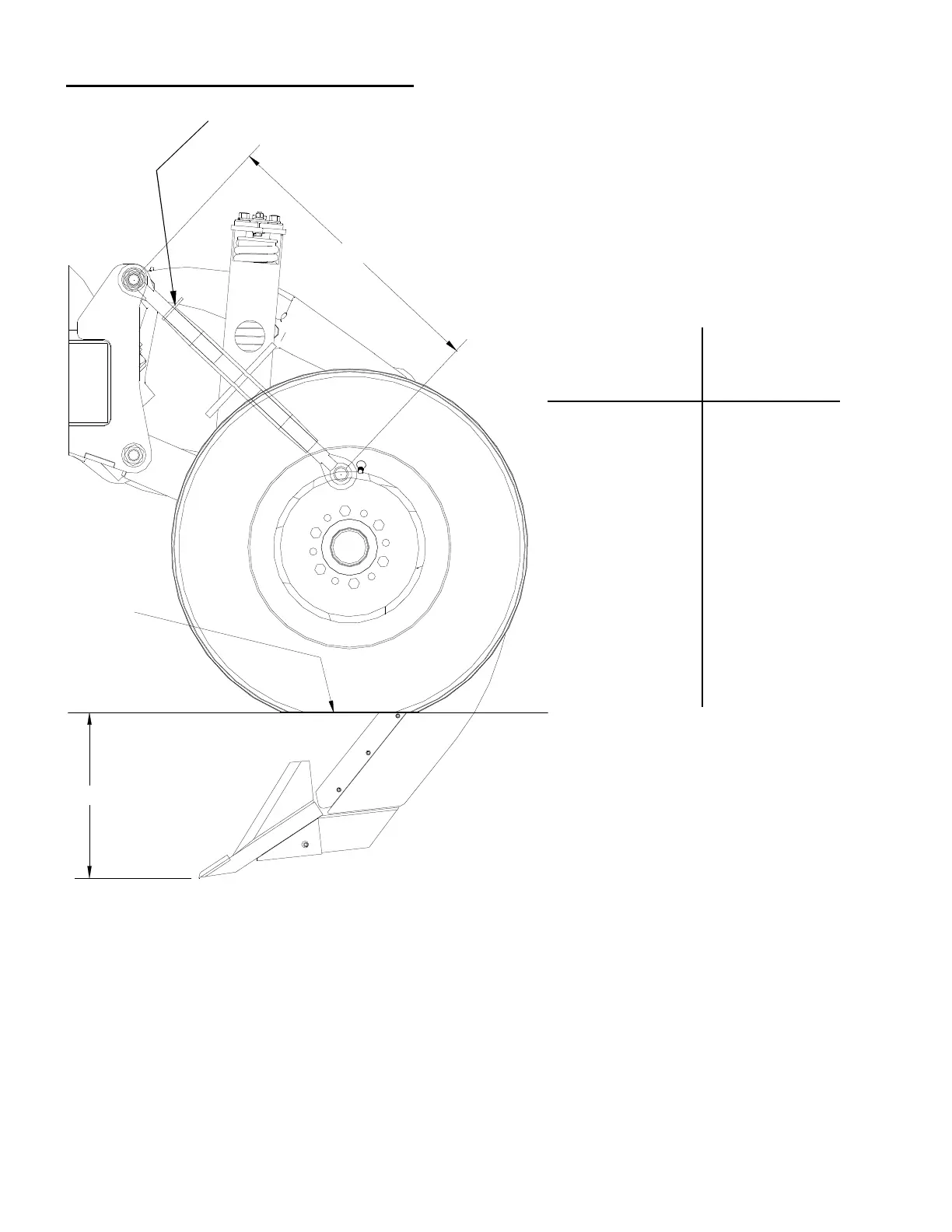

LENGTH

DEPTH

GROUND

SURFACE

Toolbar Gauge Wheel Adjustment

TURNBUCKLE

LENGTH

WORKING

SHANK

DEPTH

20 1/2” 18”

21 1/4” 17”

22” 16”

22 1/2” 15”

23” 14”

23 1/2” 13”

24” 12”

24 3/4” 11”

25 1/2” 10”

The toolbar gauge wheel, on the back 7x7 toolbar of the Rip Strip machine, is used to gauge the

working depth of the shank. Any adjustments done to the height of the toolbar gauge wheel will

directly affect the depth at which the shank penetrates the ground. Adjusting the height of the gauge

wheel is done through the turnbuckle that holds the main gauge wheel arm to the gauge wheel mount

bracket. (See “Assembly Set-Up” instructions for more information.) To adjust the height of the gauge

wheel simply twist the turnbuckle in or out until the desired tire height is achieved. Above is a chart

showing the length between the pin locations on the turnbuckle and the corresponding working shank

depths. Since the toolbar is held up by multiple gauge wheels, it will be necessary to adjust each gauge

wheel to the same turnbuckle length. Once all the turnbuckles have been adjusted lock the distance

with the turnbuckle jam ring.

TURNBUCKLE

JAM RING

Loading...

Loading...