58

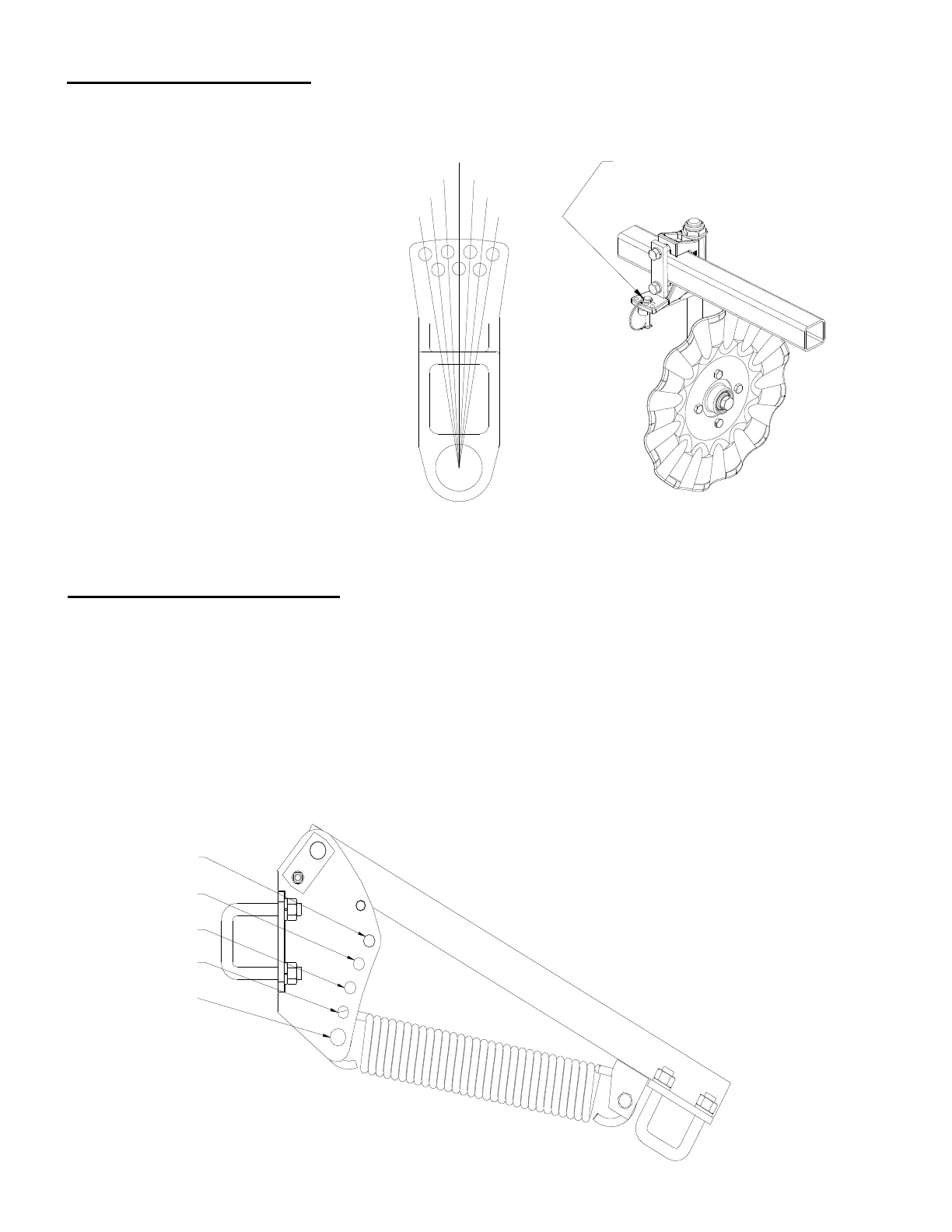

Tillage Tool Adjustment

The operating angle of the secondary

tillage tool is determined by the location of

the 3/8” adjustment pin. The figure to the

right shows the available running angles

from 0° to 9° to the left and to the right. To

adjust the operating angle, remove the

adjustment pin, turn the tillage shaft until

the hole in lower flag aligns with the

desired adjustment hole, and reinsert the

adjustment pin. It should be noted that the

tillage stem is held in place by a 1-1/4

Nylon Locknut. If this locknut needs

adjusting, be sure that it is tight enough to

hold the tillage stem stable but not so tight

that it will not allow the stem to rotate. Soil

conditions will normally dictate the angle

of the disc or wheels. Soft or conventional

soils will generally require less angle than

strip or no-till soils.

9°

6°

3°

0°

3°

6°

9°

ADJUSTMENT PIN

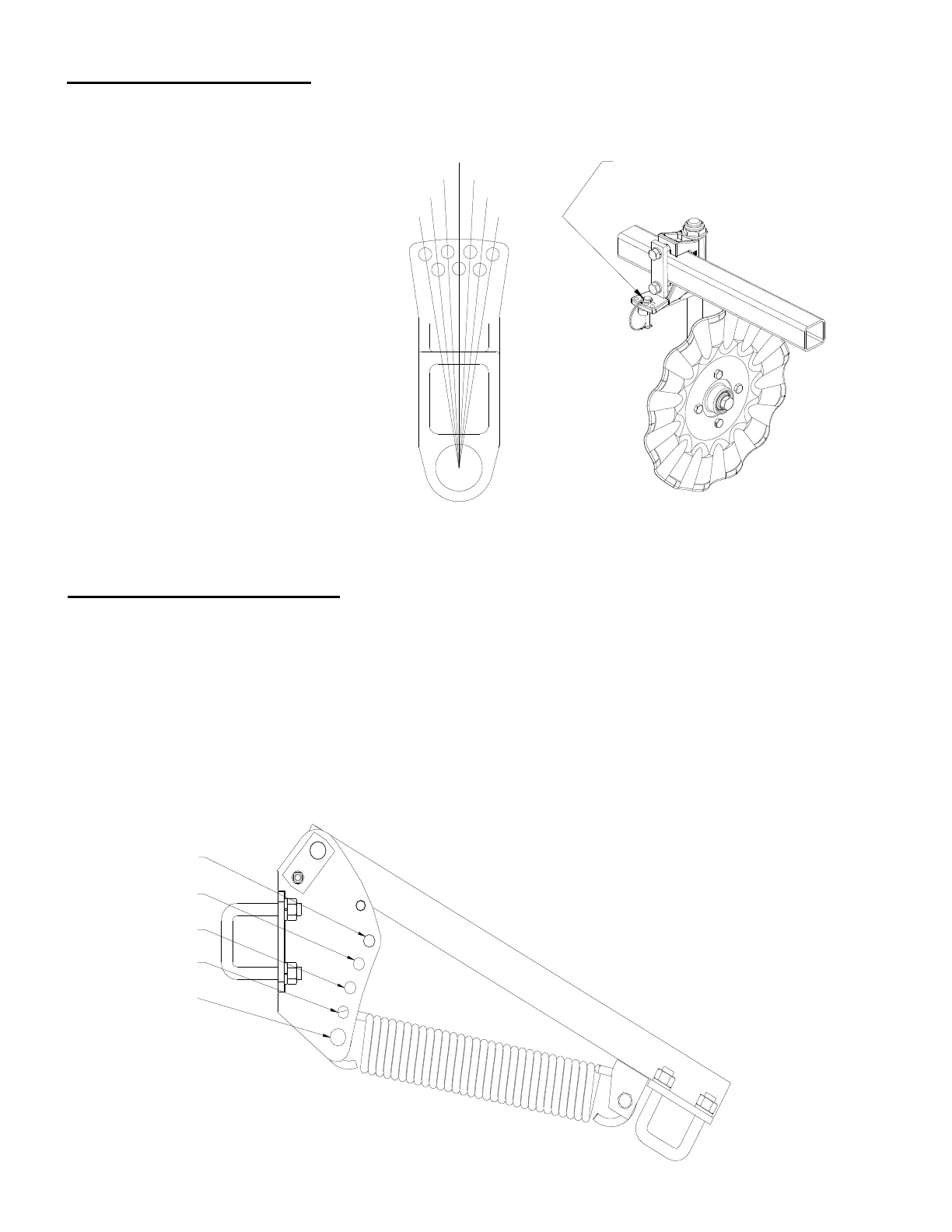

Finishing Tool Adjustment

30 LB

50 LB

80 LB

115 LB

150 LB

KMC offers a choice of finishing tools that include either a rubber tire roller or a crumbler basket. Both

types of finishing tools are attached to the toolbar using a spring loaded reach arm that provides down

pressure. To adjust the down pressure on the finishing tool, raise the main toolbar until all spring

tension in the down pressure spring is released and the finishing tool is off the ground. Remove the

adjustment pin from the front mount bracket while supporting the down pressure spring. Raise or lower

the spring until the spring hook is aligned with the desired adjustment hole and reinsert the adjustment

pin. The figure below shows the adjustment holes in the front mount bracket and their corresponding

down pressure forces.

Loading...

Loading...