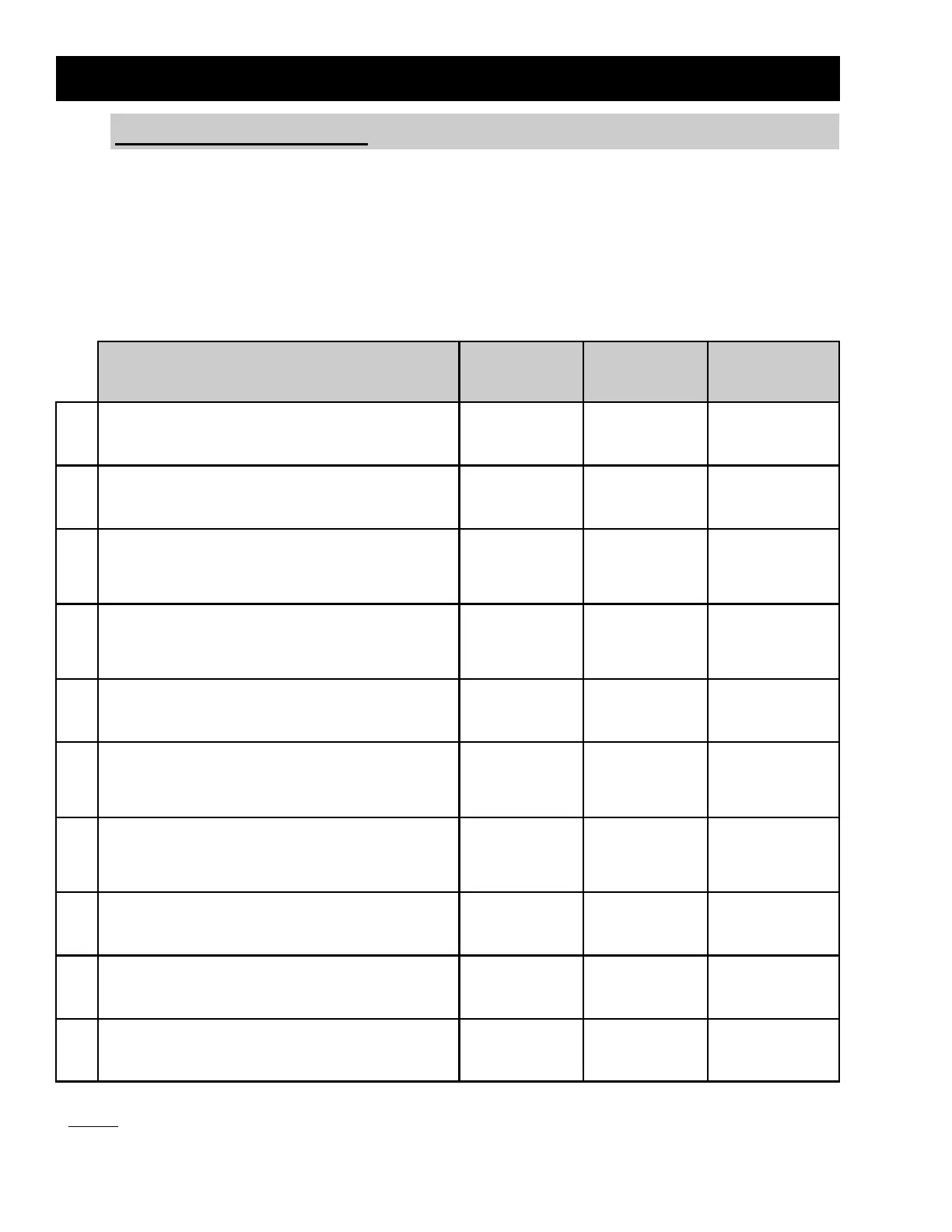

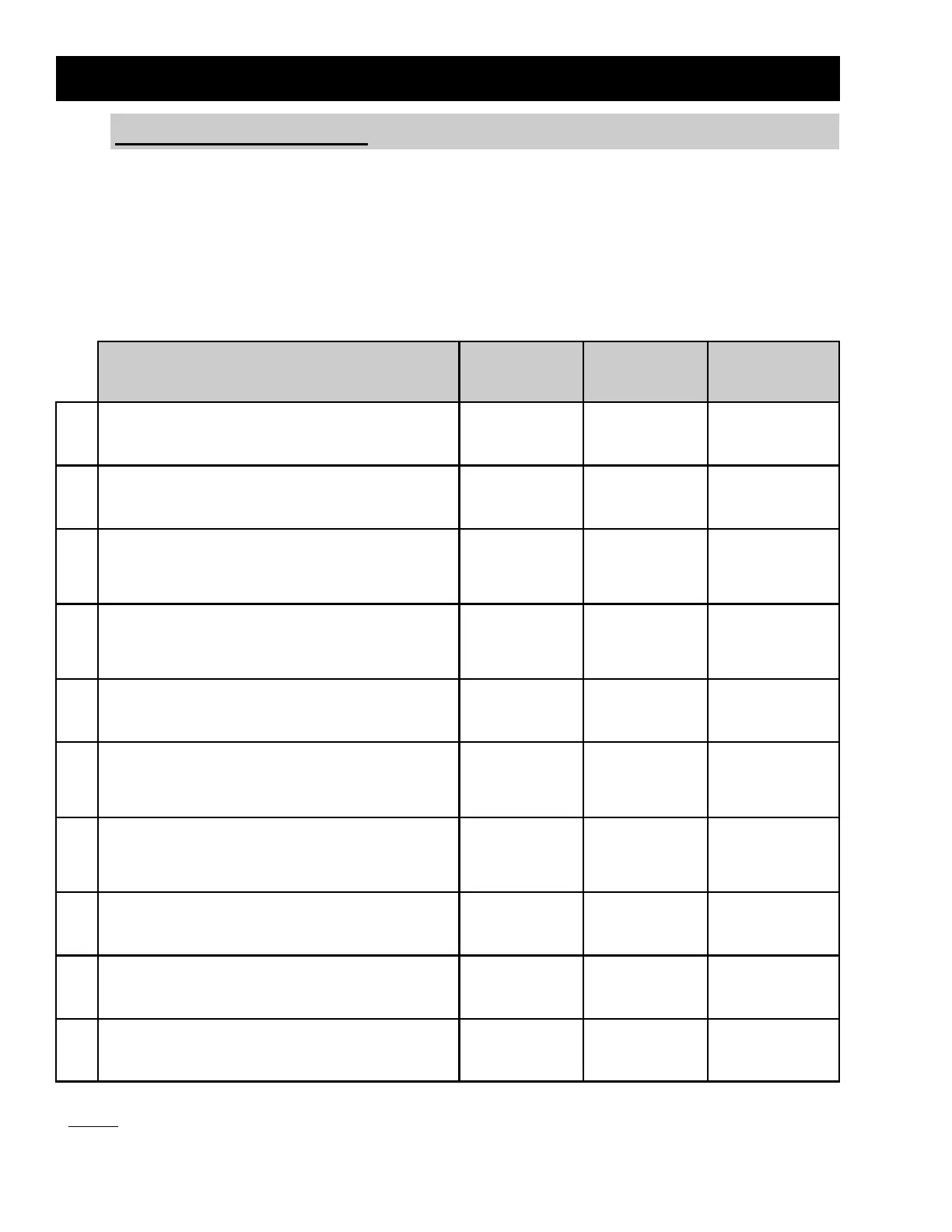

60

MAINTENANCE

The 6700 KMC Rip Strip has been carefully designed and manufactured to provide years of de-

pendable service. To maximize use and reduce downtime and repair costs, regular maintenance should

be performed on the Rip Strip. Below is a guide for minimum recommended services and the time in-

tervals for their completion. However, since these machines are used in many different conditions and

applications, the operator should customize the maintenance schedule to best fit their individual needs.

SERVICE

EVERY

10 HOURS

EVERY

50 HOURS

EVERY

250 HOURS

1

INSPECT RIPPER POINTS

(REPLACE AS NEEDED)

X

2

INSPECT WEAR SHINS

(REPLACE AS NEEDED)

X

3

LUBRICATE ALL GREASE POINTS

(see Lubrication Points in the Maintenance

section of this manual)

X

4

CHECK TORQUE ON ALL BOLTS

(See Bolt Torque Chart in Section

on General Assembly Set-up)

X

(INITIAL)

X

5 INSPECT HITCH PINS FOR WEAR X

6

INSPECT FRONT COULTER AND ALL

TILLAGE DISC

(REPLACE AS NEEDED)

X

7

INSPECT BEARINGS

ON ALL COULTERS, GAUGE WHEELS

AND TILLAGE/FINISHING TOOLS

X

8

INSPECT RIPPER SHANKS AND TRIP

MECHANISMS FOR ANY DAMAGE

X

9 INSPECT TOOLBAR FOR ANY DAMAGE X

10

INSPECT TIRE PRESSURE IN ALL

GAUGE AND PRESS WHEELS

X

*NOTE: Front Coulter bearings, Cover Crop Roller bearings, Tillage Disc bearings and Crumbler/

Roller bearings are all non-relube.

SERVICE SCHEDULE

Loading...

Loading...