TP-6694 7/1868 Section 3 Scheduled Maintenance

To change the fuel type, change the electrical

connections to the engine ECM. The engine ECM has

fuel tables and spark advance curves programmed for

both natural gas and LPG. The information following, in

Figure 3-3, and in Figure 3-5 generally apply to all

models and all fuels. Be sure to review the respective

wiring diagram for your specific model for possible

special applications.

Natural Gas Operation

D Disconnect lead 65 from lead N5.

D Disconnect lead 73B from the fuel valve.

D Connect lead 73A to the fuel valve.

LPG Vapor Operation

D Disconnect lead 73A from the fuel valve.

D Connect lead 73B to the fuel valve (LPG vapor).

D Connect lead 65 to lead N5 (ground).

LPG Liquid Withdrawal Operation

D Disconnect lead 73A from the fuel valve.

D Connect lead 73B to the fuel valve (LPG liquid

withdrawal).

D Connect lead 65 to lead N5 (ground).

Auto Changeover Natural Gas/LPG Vapor

Operation

D Disconnect lead 65 from N5.

D Connect lead N5 to LFP2 relay common terminal.

D Connect lead 73A to the fuel valve (natural gas).

D Connect lead 73B to the fuel valve (LPG vapor).

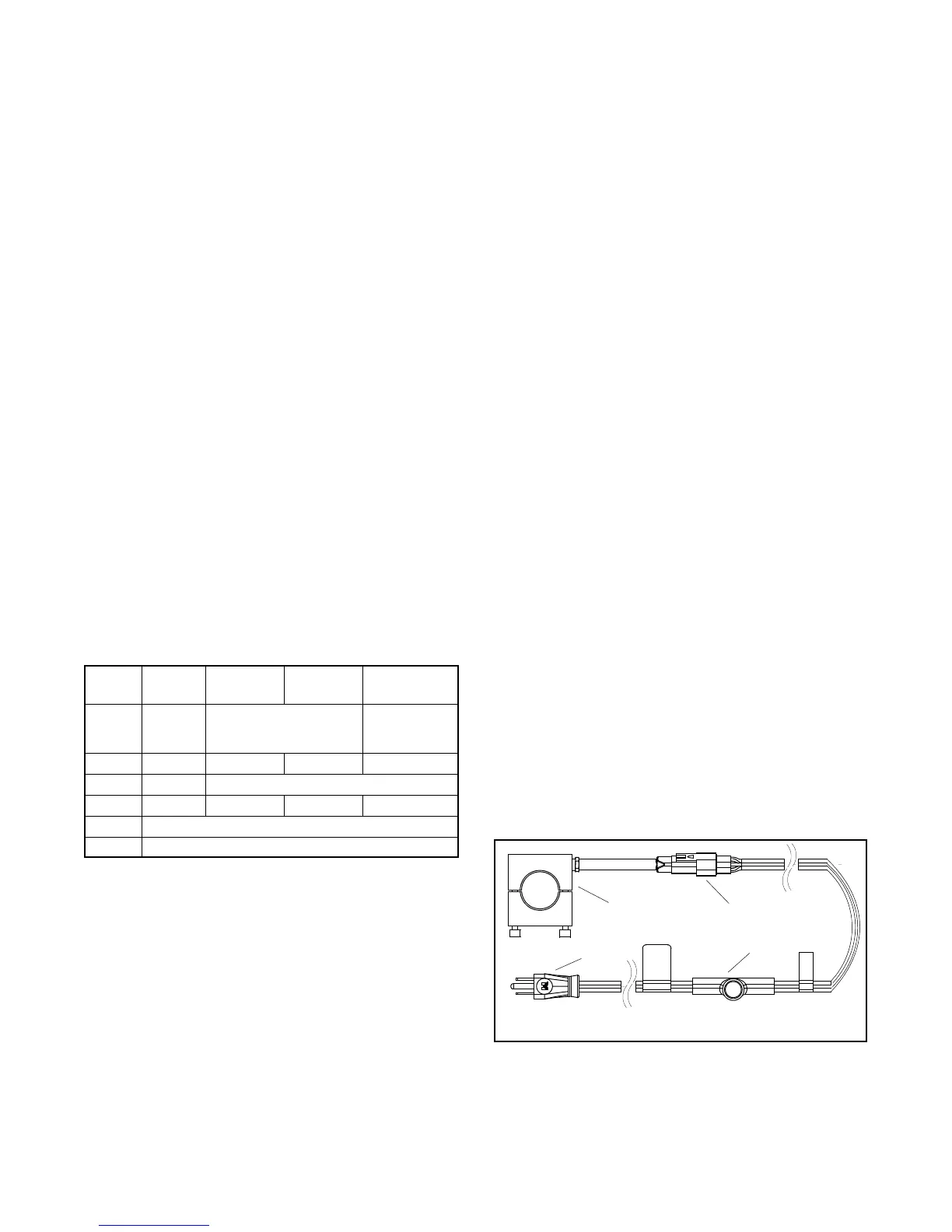

Eng.

ECM

Natural

Gas

LPG

Vapor

LPG

Liquid

Auto

Changeover

73A

QCON --7

(NG fuel

valve)

not used

QCON --7

(NG fuel valve)

N5 not used 65 65 LFP2--COM

73B not used QCON--10 (LPG fuel valve)

65 not used N5 N5 not used

63 LFP1--NC low fuel pressure sensor (if used)

70E2 P6--B (15 amp fuse)

Figure 3-3 Gaseous Fuel Electrical Connections

3.6.4 Fuel System Changeover Kits

(Dual Fuel)

Automatic Changeover

A changeover fuel system kit provides automatic

changeover from natural gas to LPG vapor. The

primary and backup fuels each have a fuel valve. The

primary fuel is natural gas; the backup fuel is LPG

vapor. Before starting, both fuel valves are closed.

When the generator set starts, the primary fuel valve

opens. The primary fuel line has a pressure switch in

series with a relay connected to the start/run circuit.

When the primary fuel pressure drops below 0.6 kPa

(1.4 oz./in.

2

) or 6.4 cm (2.5 in.) water column , a relay

opens the backup fuel valve and closes the primary fuel

valve. When the primary fuel pressure rises above 0.6

kPa (1.4 oz./in.

2

) or 6.4 cm (2.5 in.) water column, the

generator set uses the primary fuel. Contact an

authorized service distributor/dealer for kit availability.

Emissions certified models use a single electronic-

controlled pressure regulator (EPR) for both fuels. A tee

fitting connects both fuels together upstream of the

EPR. During operation when using the secondary fuel, it

is normal for a small amount of secondary fuel to seep

back through the primary fuel valve. To counter this

situation, one of two methods is used depending upon

the generator set model: (1) a second valve (identical to

the primary fuel valve) is installed in a reverse

configuration on the primary fuel side or (2) a small vent

line is installed between the primary fuel inlet and the air

intake through a solenoid valve.

3.7 Crankcase Ventilation (CCV)

Heater Kit GM78171-KP1

Applies to 125/150 kW, 8.1 L GM- and 8.8 L PSI-

powered generator set models. Consult your local

generator set distributor/dealer for additional

information.

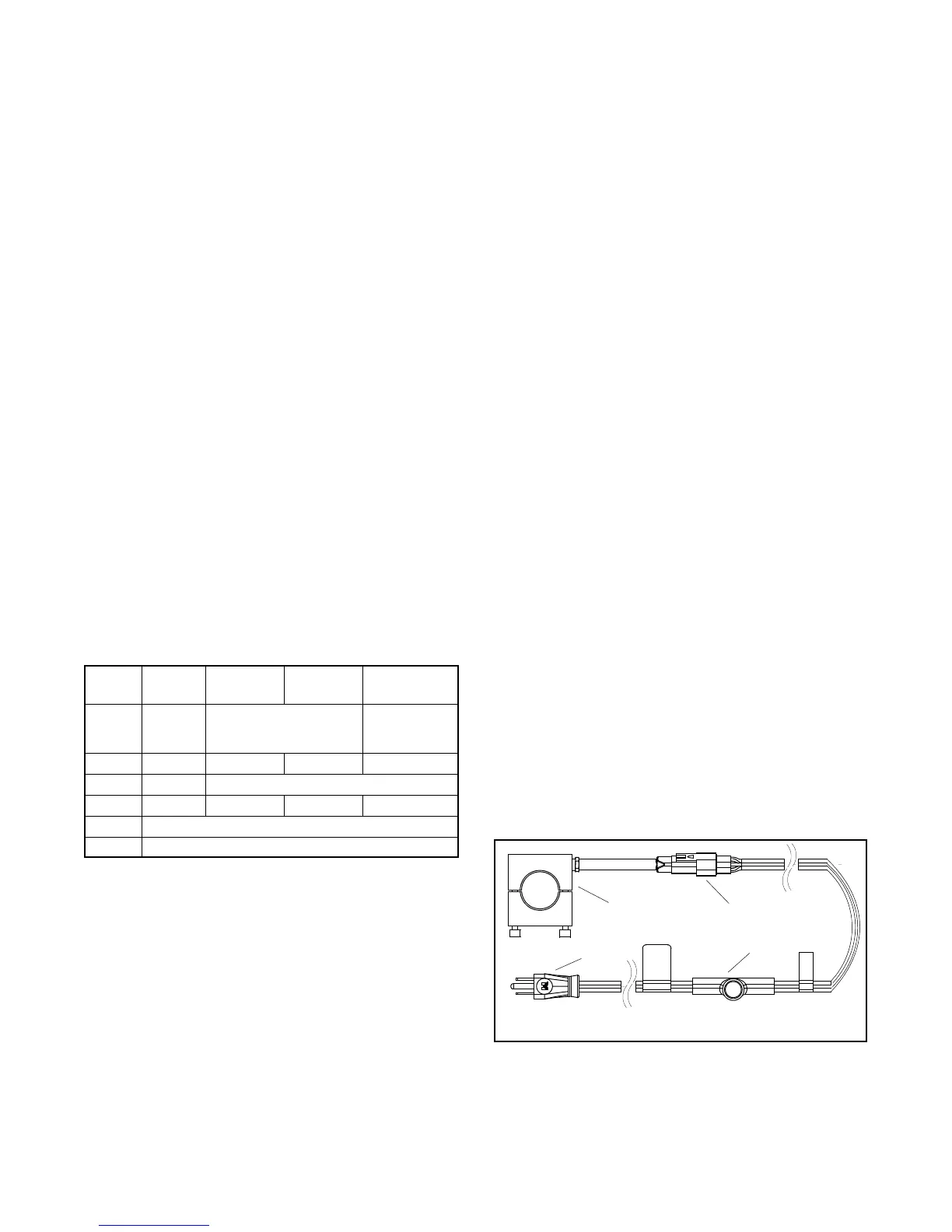

The crankcase ventilation (CCV) heater kit provides a

controlled heating source to the crankcase ventilation

system preventing freezing water buildup during cold

weather. The thermostat turns on at 4_C(40_F) and

turns off at 16_C(60_F) reducing energy consumption.

SeeFigure3-4.

1. Heater element

2. Inline connector

TT-1560

1

2

3

4

3. Thermostat

4. AC power cord

Figure 3-4 Crankcase Ventilation Heater Kit

Loading...

Loading...