TP-6694 7/1870 Section 3 Scheduled Maintenance

3.8 Air Cleaner Restrictor Indicator

(if equipped)

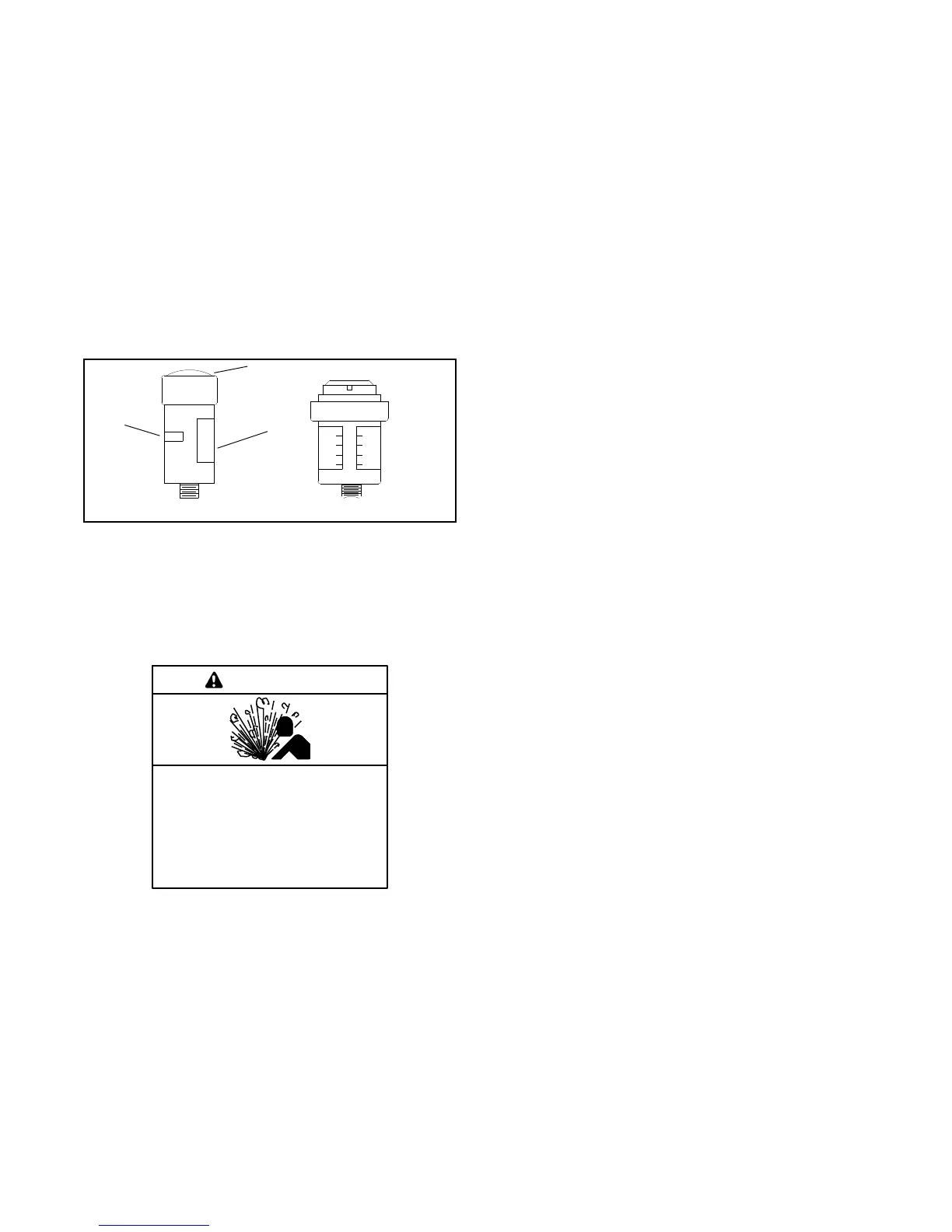

The air cleaner restriction gauge mounted on the air

cleaner(s) helps determine the air cleaner change

interval.

The air cleaner restriction gauge monitors air flow and

continuously displays restriction readings indicated as

vacuum (see Figure 3-6). Increased restriction

indicates a clogged air cleaner element.

As maximum allowable restriction is reached, the gauge

window turns red indicating the air cleaner element

needs replacement. To reset the gauge, push the gauge

top down and release.

273113

10

15

19

22

25

1

2

3

1. Push down to reset 2. Display 3. G auge window

Figure 3-6 Restriction Indicators (styles vary)

3.9 Cooling System

The cooling system maintenance information applies to

radiator-cooled models which have a radiator with a

pressure cap and coolant recovery tank.

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap,

stop the generator set and allow it to

cool. Then loosen the pressure cap

to relieve pressure.

WARNING

Allow the engine to cool. Release pressure from the

cooling system before removing the pressure cap. To

release pressure, cover the pressure cap with a thick

cloth and then slowly turn the cap counterclockwise to

the first stop. Remove the cap after pressure has been

completely released and the engine has cooled. Check

the coolant level at the tank if the generator set has a

coolant recovery tank.

Note: Engine damage. Bleed the air from the cooling

system to prevent overheating and subsequent

engine damage.

Note: Block heater damage. The block heater will fail

if the energized heater element is not immersed

in coolant. Fill the cooling system before turning

on the block heater. Run the engine until it is

warm, and refill the radiator to purge the air from

the system before energizing the block heater.

3.9.1 Coolant Level Ch eck

Check the coolant level in the coolant recovery tank.

Maintain the coolant level between the high and low

marks.

Note: Periodically check the coolant level by removing

the pressure cap. Do not rely solely on the level in

the coolant recovery tank. Add fresh coolant until

the level is just below the overflow tube opening

of the filler neck.

3.9.2 Cooling System Component

Inspection

To prevent generator set shutdown or damage caused

by overheating:

D Keep the cooling air inlets clean and unobstructed.

D Inspect the radiator’s exterior for obstructions.

Remove dirt and foreign material using a soft brush or

cloth to avoid damaging the radiator fins.

D Check the hoses and connections for leaks. Replace

any cracked, frayed, or spongy hoses.

D Check the condition and tension of the radiator fan

and water pump belt(s). Follow the belt tension

procedure in this manual and/or the engine operation

manual.

D Check the pressure cap seal and replace a cracked or

deteriorated cap. Remove dirt and other debris from

the pressure cap and filler neck. The pressure cap

raises the boiling point of the coolant, enabling higher

operating temperatures. Replace a leaking pressure

cap with one rated for the same pressure. The

pressure cap rating usually appears on the pressure

cap.

Loading...

Loading...