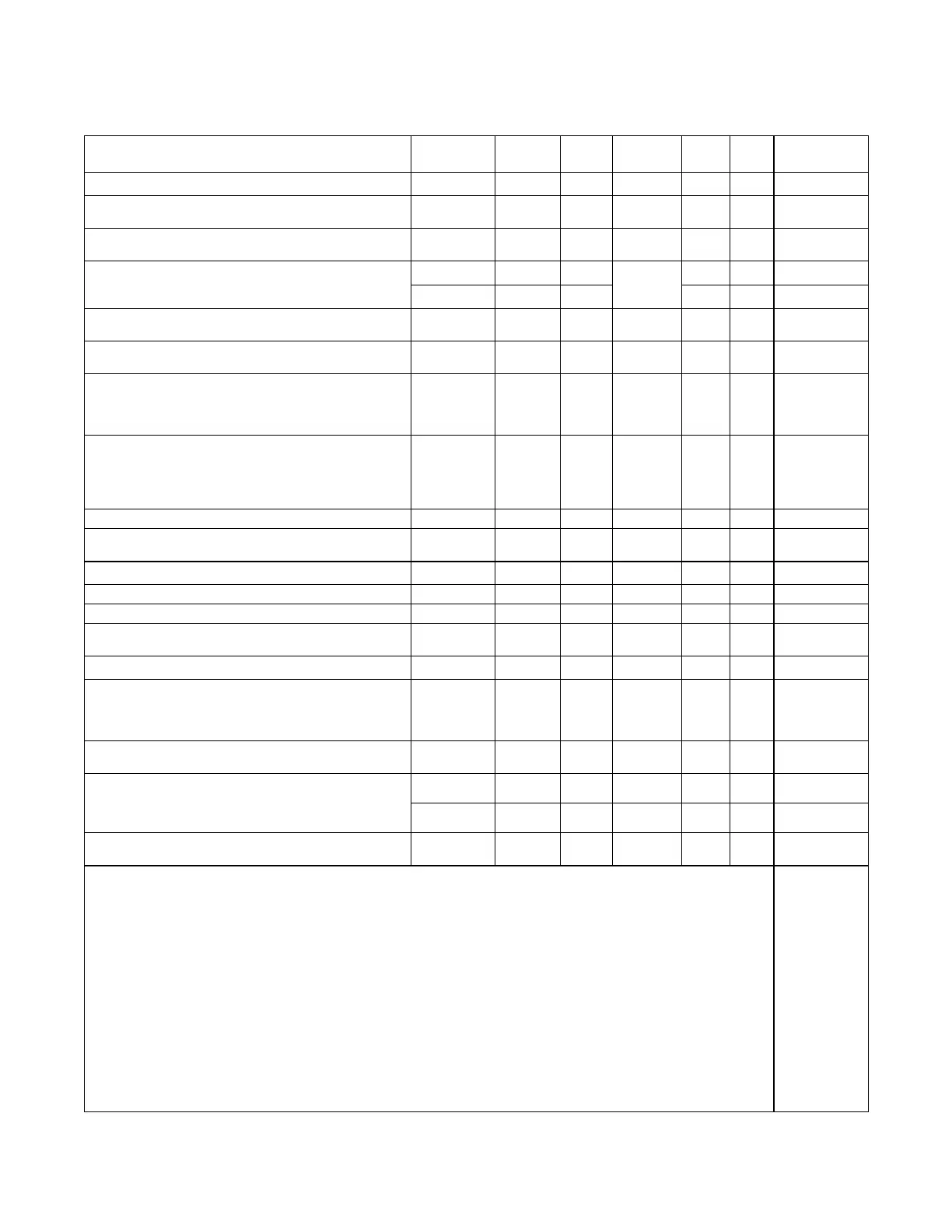

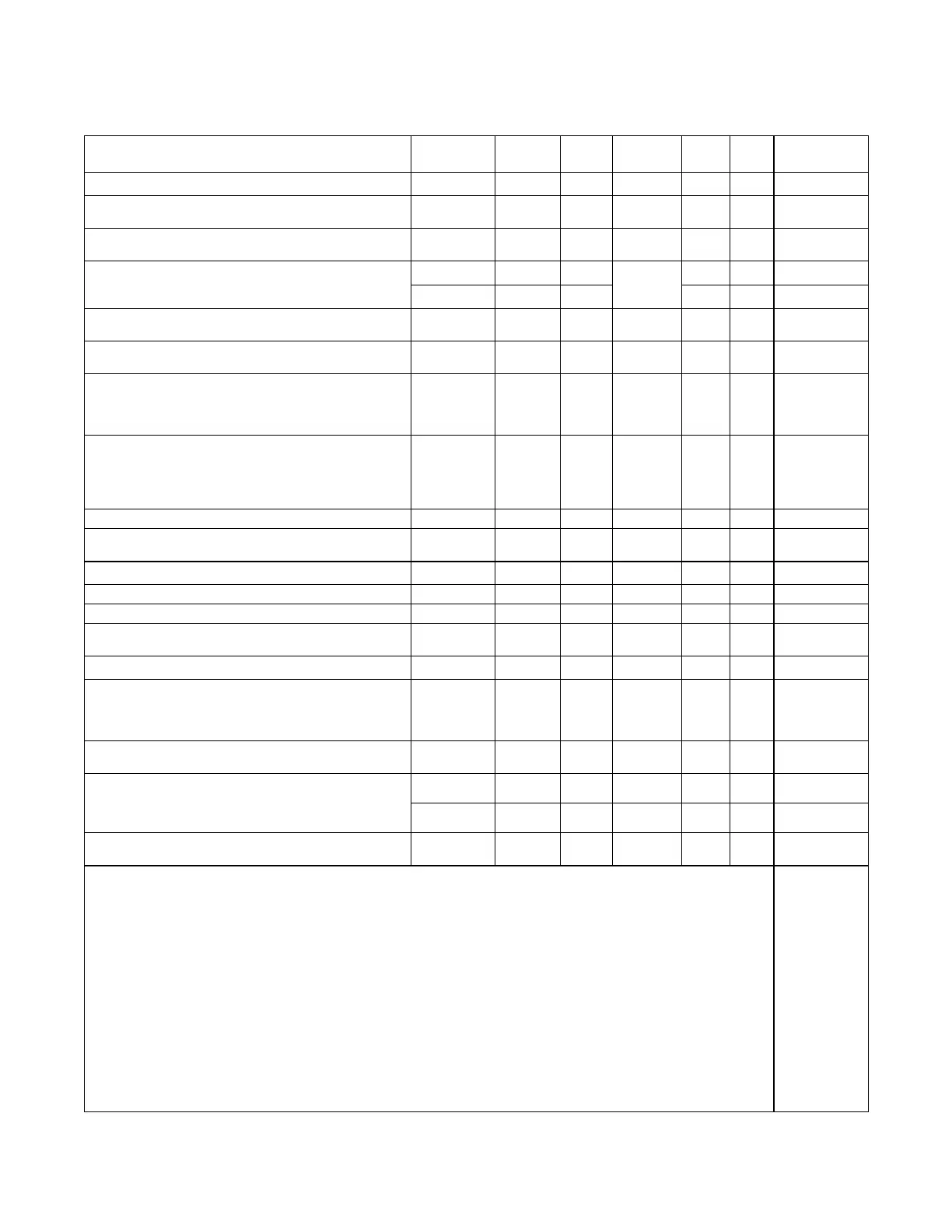

TP-5660 11/9820 Scheduled Maintenance

4.3 Service Schedule

Follow the service schedule below for the recommended service intervals. Have all service performed by an

authorized service center except for activities limited to the items designated by an X.

System Component or Procedure

See

Section

Visually

Inspect

Check Change Clean Test

Frequency

ELECTRICAL SYSTEM

Check for signs of overheating or loose connections:

discoloration of metal, melted plastic, or a burning odor

4.1.1 X X M

Check the contactor’s external operating mechanism

for cleanliness and clean and relubricate if dirty *

4.1.1 X

D, R

(lubricant)

D M

Check wiring insulation for deterioration, cuts, or

4.1.1 X

M

properties of the original wiring

4.1.2 D D

(wiring)

Q

Check the transfer switch’s main power switching

mechanisms’ mechanical operation and integrity

4.1.2 D D D Y

Tighten control and power wiring connections to

specifications

4.1.2, 6.4, L D D Y

Check the transfer switch’s main power switching

contacts’ condition and clean or replace the main

contacts or replace the contactor assembly as

necessary

4.1.2 D D, R D Y

Perform a thermal scan or millivolt drop test to check

for high contact resistances on power circuits. Tighten

connections, clean main contacts, adjust or replace

main contacts or contactor assembly to eliminate high

contact resistances

4.1.2 D D, R D D Y

Test wire and cable insulation for electrical breakdown 4.1.2 D Every 3 Years

Check calibration of voltage-sensing circuitry and

setpoints, and recalibrate circuitry as necessary

4.1.2 D D Every 5 Years

CONTROL SYSTEM

Exercise the generator set under load 4.2.1, L X W

Test the transfer switch’s automatic control system 4.2.2, L X X M

Test all indicators (incandescent lamps and LEDs) and

all remote control systems for operation

L D D D, R D Y

GENERAL EQUIPMENT CONDITION

Inspect the outside of the transfer switch for any

condition of vibration, leakage, noise, temperature,

contamination, or deterioration to keep the transfer

switch clean and in good condition *

4.1.1 X X W

Check that all external hardware is in place, tightened,

and not badly worn

4.1.1 X X R W

Inspect the inside of transfer switch for any condition of

4.1.1 X X D M

or deterioration to keep the inside of the transfer switch

clean, dry, and in good condition *

4.1.2 D D D Y

Check that all internal hardware is in place, tightened,

and not badly worn

4.1.2 X D M

* Service more frequently if operated in dusty or dirty areas.

See Section Read these sections carefully for additional information before attempting maintenance or service.

Visually Inspect Examine these items visually.

Check Requires physical contact with or movement of system components, or the use of nonvisual indications.

Change May require replacement of components depending upon the severity of the problem.

Clean Removeaccumulationsofdirtandcontaminantsfromexternaltransferswitch’scomponentsorenclosurewithavacuum

cleaner or by wiping with a dry cloth or brush. Do not use compressed air to clean the switch because it can cause debris to

lodge in the components and cause damage.

Test May require tools, equipment, or training available only through an authorized service center.

L See the transfer switch logic controller operation and installation manual for more information.

D Have service performed by an authorized service center.

X Operator action.

R May require replacement of components.

W=Weekly

M=Monthly

Q=Quarterly

S=SixMonths

Y=Yearly

Loading...

Loading...