new 60 Series Service Manual.rev. 06.01.16.docx - 5 –

Pre-Install Checklist

• Ambient air temperatures at the install location are between 45°F (7°C) and 90°F(32°C), the

machine must be installed indoors.

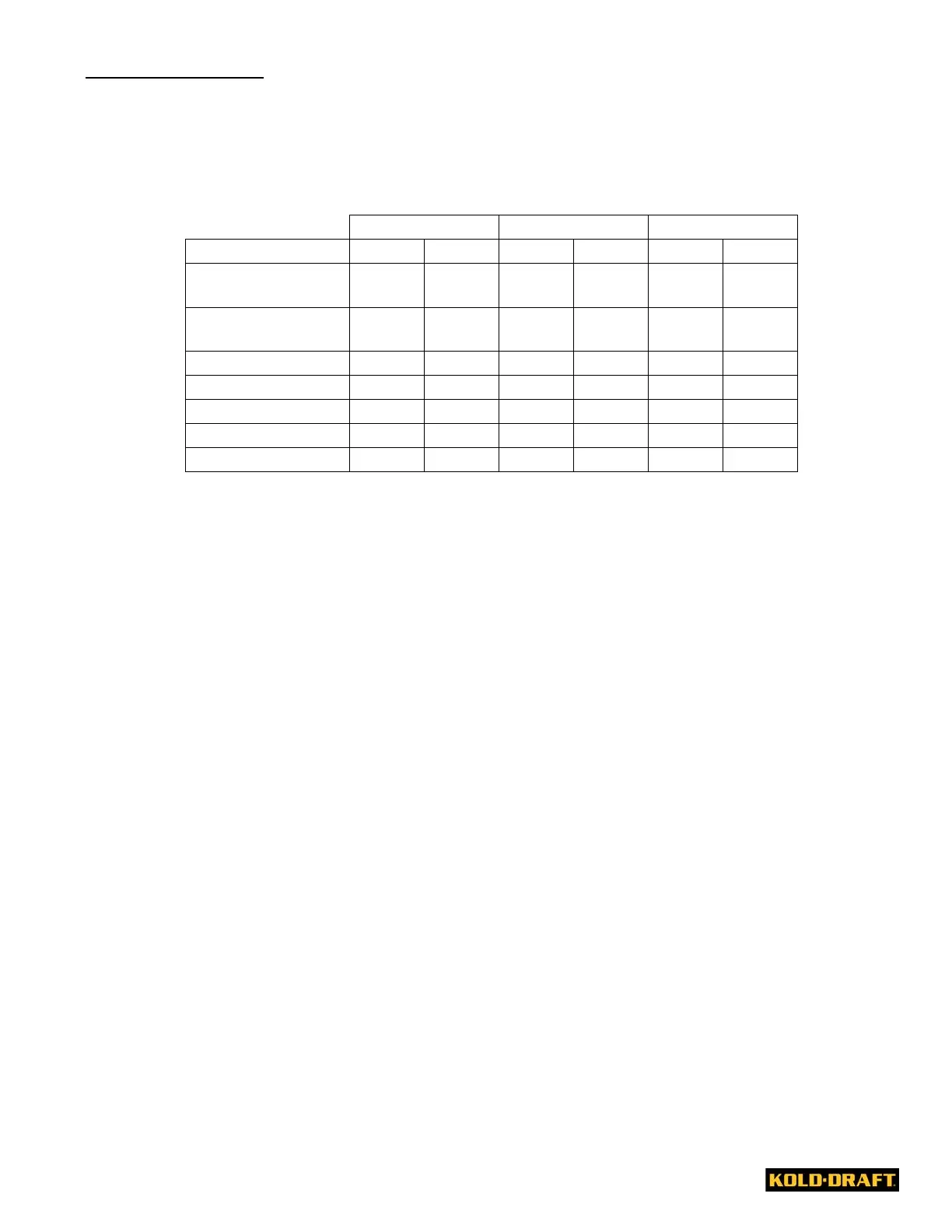

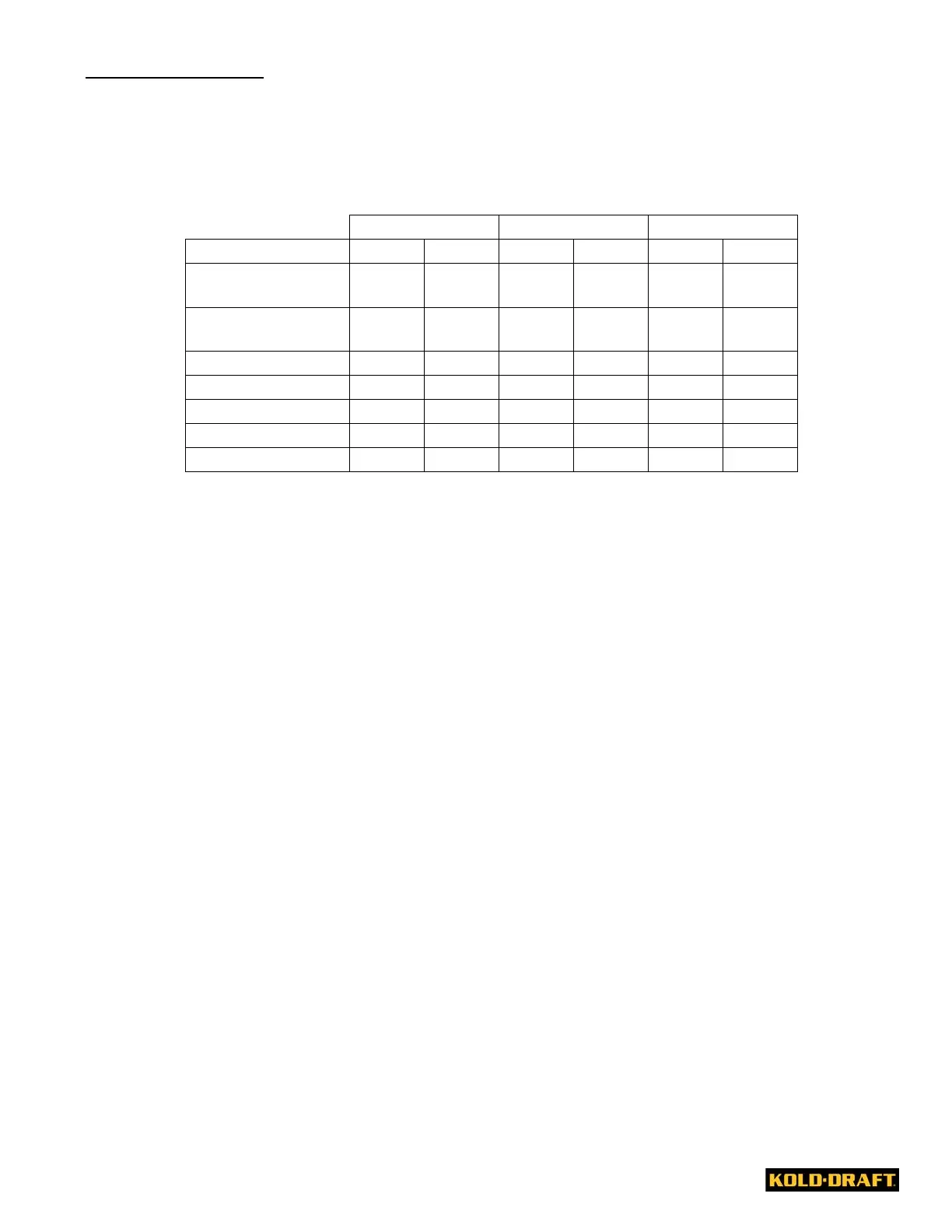

• The machine will have the minimum opening sizes listed below. Heights listed are strictly the

ice machine and do not include the height of the bin. Depths listed are adjusted to

accommodate plumbing and electrical hookups.

• Each ice maker and each ice bin must enter the drain stack through separate connections.

Models equipped with a liquid condenser that does not recirculate coolant must have a drain

for each condenser that enters the drain stack through separate connections

• The drain hose or pipe will remain a constant diameter from the machine to the drain

o The building drain must be able to accommodate all the drain water from the ice

machine operation.

• Individual drains will not be directly connected to a common manifold, drain or standpipe. If

individual drains are to be discharged into a common manifold, drain or standpipe, a minimum

38mm (1.5”) air gap must be provided at each connection. This is to prevent any backflow of

drain water into the ice maker or ice bin.

• Drain lines will be installed with a minimum drop of 1” per 3’ run (2.5cm per meter run).

• The temperatures of the water supply fall between 45°F (7°C) and 90°F(32°C)

• The water supply must be potable, not laden with sediment and have free chlorine levels no

greater than 0.2ppm.

• A minimum 5 psig (0.034 MPa) dynamic water supply pressure is required for proper

operation of the ice maker water valve. Please note that on liquid cooled ice machines, where

the same water supply is used for both condenser cooling and the potable water supply, the

demand for condenser coolant may cause the supply pressure to drop. This is most notable

at the time of peak load, at the beginning of the freeze cycle. The maximum water supply

pressure is 100 psig (0.6 MPa).

• All water lines have been purged before connection.

• All KOLD-DRAFT models are intended to be installed with a permanent connection to the field

electrical supply. Drop cord connections are not to be used with this equipment. Always be

sure the power supply is the same as the ice machine’s electrical specification, which is listed

on the serial number tag on the front of the top frame cross member

• Each ice maker must be connected to the grid through its own dedicated fuse or HACR type

circuit breaker.

• Each ice maker must be connected to a separate protected circuit with no other loads.

• Fused disconnects, installed adjacent to each ice maker, are recommended and may be

required by local codes. These components must be supplied by the installer.

Loading...

Loading...