Maintenance - Section 42 07/09 0M4211

Page 42-16 Automatic Lubrication System

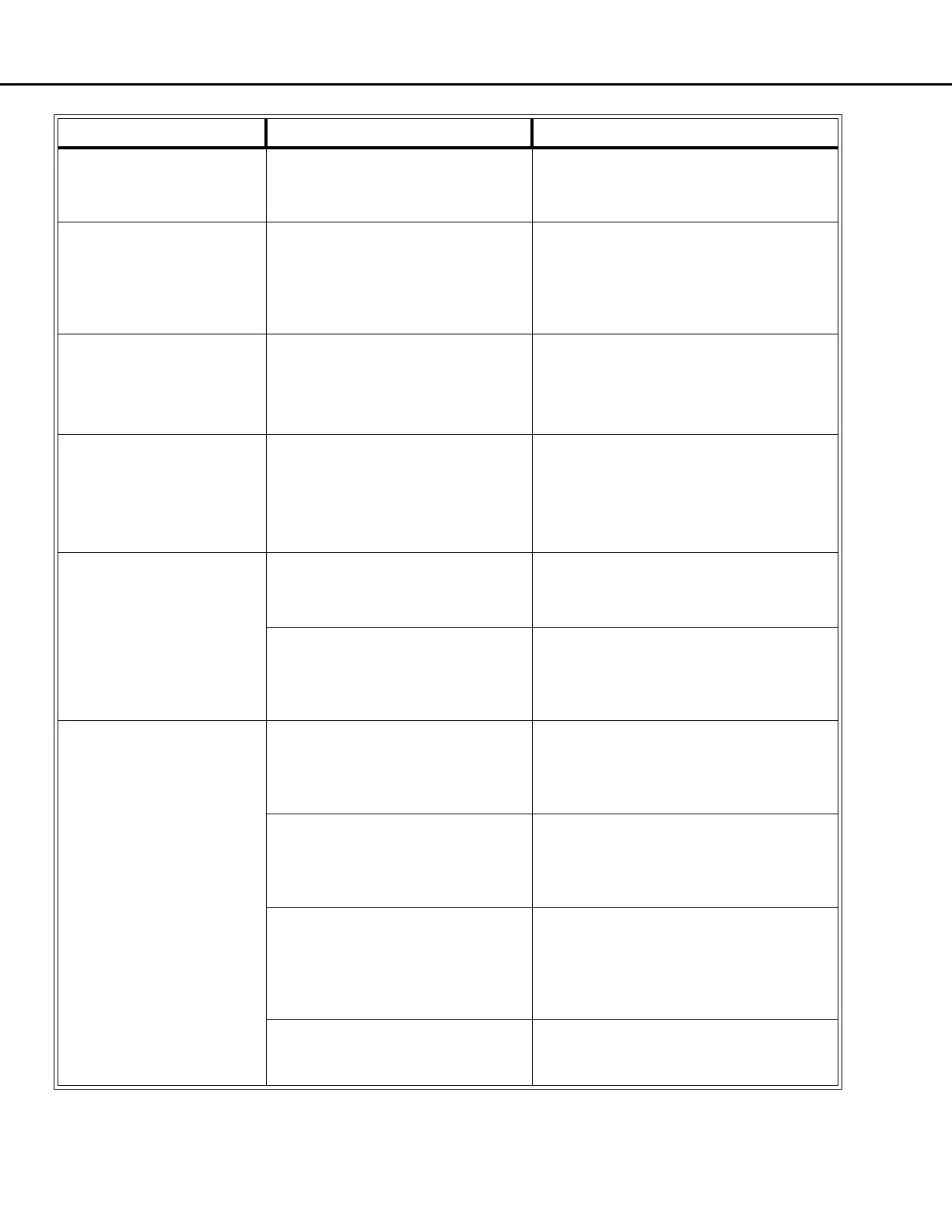

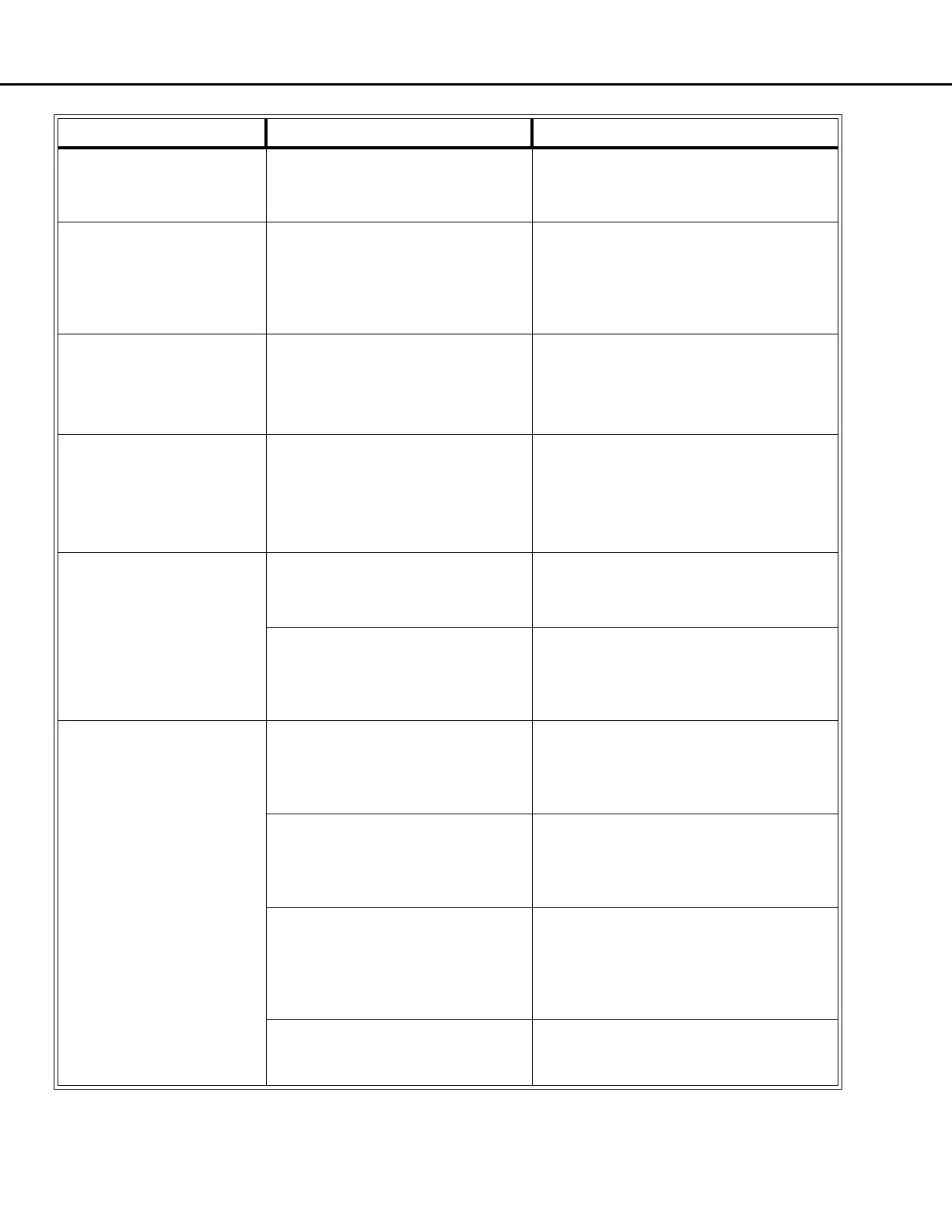

PROBLEM POSSIBLE CAUSES SUGGESTED CORRECTIVE ACTION

Pump Pressure Builds

Very Slowly Or Not At All.

No signal at solenoid.

Check timer.

Controller Does Not

Operate.

No electric power to controller.

Turn on electric power to pump. Power

LED must light, pump on LED must light

when manual lubrication is pressed.

Pump On LED Lights, But

Load Connected To

Terminals 3 & 4 Will Not

Energize.

Printed circuit board failure. Remove and replace.

Load Connected To

Terminals 3 & 4

Energized, But Pump On

LED Does Not Light.

Printed circuit board failure or key-

pad failure.

Remove and replace.

Bearing Points

Excessively Lubricated.

Controller memory mode is off. Switch controller memory mode to on.

Injector output adjustment setting

too high.

Readjust to lower setting.

Bearing Points Are Not

Sufficiently Lubricated.

Timer/controller cycle time setting

too low.

Set to longer cycle time or re-evaluate

lubrication requirements.

Injector output adjustment setting

too low.

Readjust injector output setting.

Timer/controller cycle time setting

does not deliver lubricant often

enough.

Set to shorter cycle time or re-evaluate

lubrication requirements.

System too large for pump output. Calculate system requirements per

planning manual.

Loading...

Loading...