Torque Tables And Conversion Charts - Section 12 02/11 OM1200

Page 12-4

STANDARD TIGHTENING TORQUES

For SAE Grade 9 Cap screws

The following specifications apply to required assem-

bly torques for all 12-point, grade 9 (170,000 psi min-

imum tensile), cap screws.

• Cap screw threads and seats shall be lubricated

when assembled.

Unless instructions specifically recommend

otherwise, these standard torque values are to be

used with simple lithium base chassis grease (multi-

purpose EP NLGI) or a rust- preventive grease (see

list, this page) on the threads.

• Torques are calculated to give a clamping force

of approximately 75% of proof load.

• The maximum torque tolerance shall be ±10% of

the torque value shown.

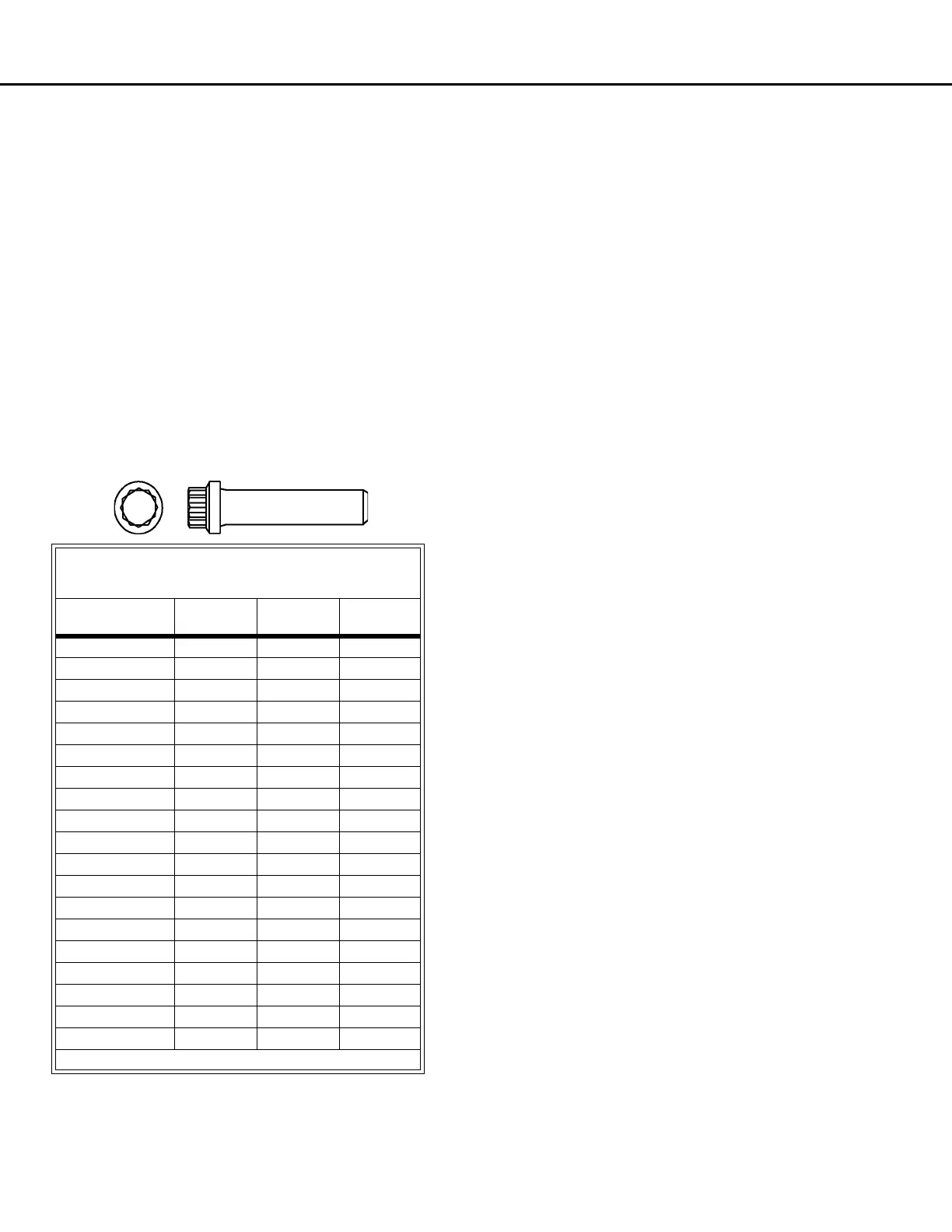

TABLE 3.

Standard Tightening Torque

for 12-Point, Grade 9 Cap Screws

Cap Screw Size*

Torque

N·m

Torque

ft lb

Torque

kg·m

0.250 - 20 16 12 1.7

0.312 - 18 33 24 3.3

0.375 - 16 57 42 5.8

0.438 -14 95 70 9.7

0.500 -13 142 105 14.5

0.562 - 12 203 150 20.7

0.625 - 11 278 205 28.3

0.750 - 10 488 360 49.7

0.875 - 9 780 575 79.4

1.000 - 8 1166 860 119

1.000 - 12 1240 915 126

1.125 - 7 1670 1230 170

1.125 - 12 1800 1330 184

1.250 - 7 2325 1715 237

1.250 - 12 2495 1840 254

1.375 - 6 3080 2270 313

1.375 - 12 3355 2475 342

1.500 - 6 4040 2980 411

1.500 - 12 4375 3225 445

* Shank Diameter (in.) - Threads per inch

Loading...

Loading...