30

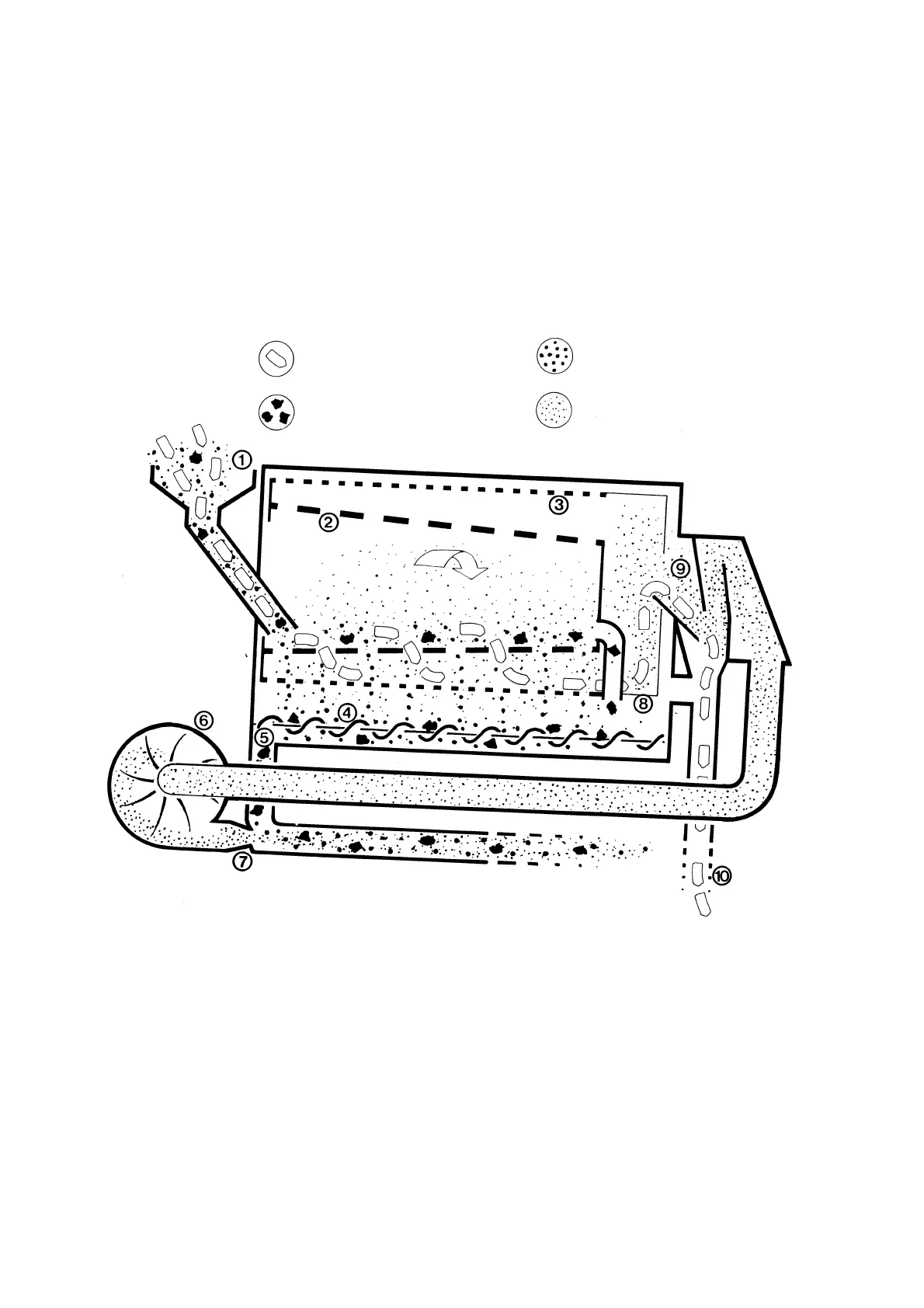

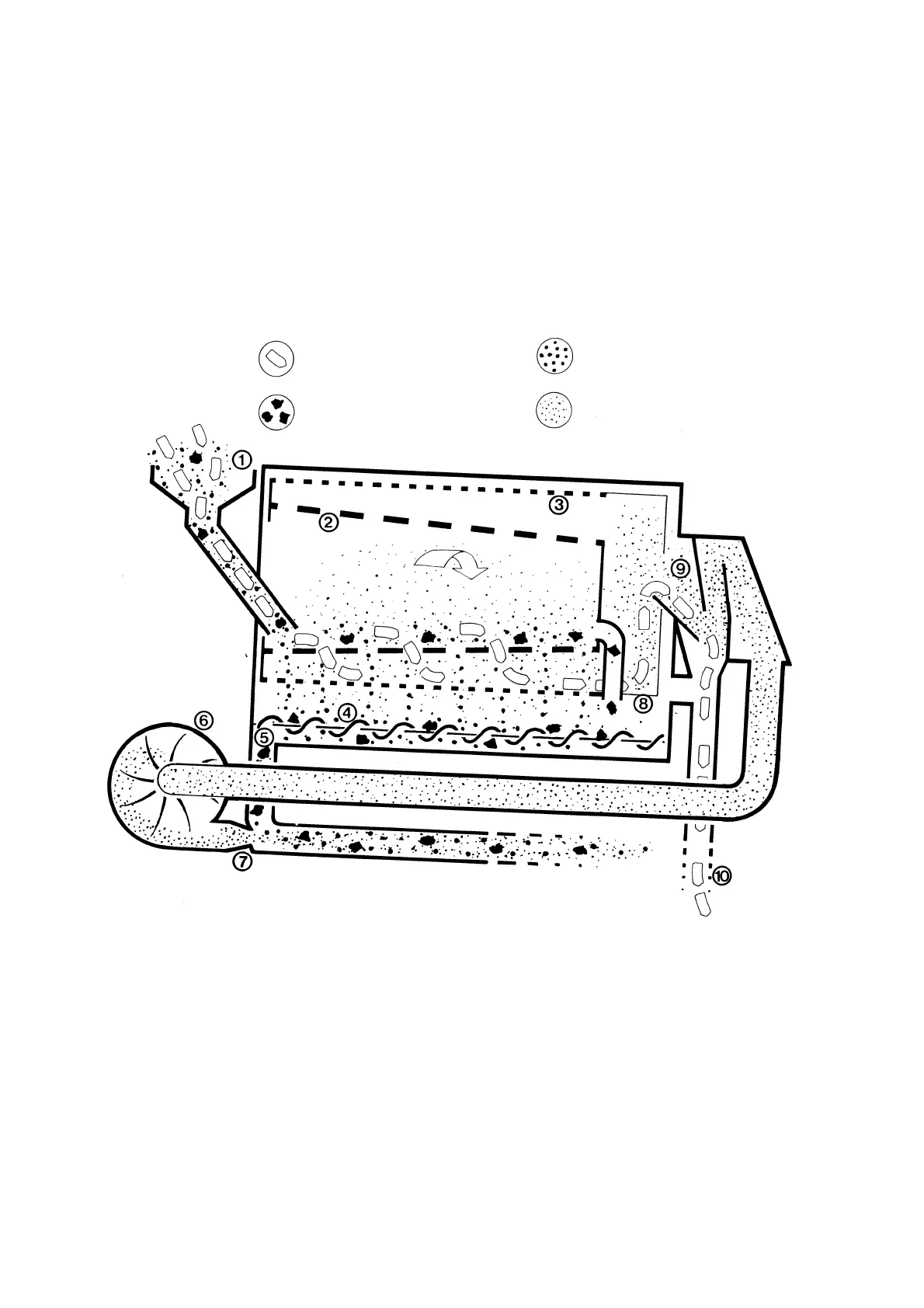

Principle of operation

Crop flow: Unclean grain flows into the conically

shaped inner screen. The inner screen hole diame-

ter allows the grain to pass through, keeping the

large impurities back.

1. Intake

2. Inner screen

3. Outer screen

4. Auger

5. Screenings outlet

Having passed through the inner screen the grain

falls onto the outer cylindrically shaped screen. Its

slot dimensions are designed to keep the grain

back and allow light impurities to fall through. The

drum containing the inner and outer screens rotates

at approx. 22 rpm.

The combi-cleaner is installet at an angle of inclina-

tion of approx. 5° to the rear, causing the crop to

move across the screens as a result of the rotary

movement of the drum.

After the mechanical cleaning, the crop is carried to

an aspiration cleaner where light impurities and

dust are extracted.

The impurities from both screens are collected in a

trough at the bottom of the unit.

At the bottom of the trough is an auger carrying the

trash to the front of the unit where the screenings

may either be disharged through a separate gravity

outlet or delivered into the trash blow line by the

combi-cleaner's fan and disharged together with the

light impurities.

The combi-cleaner is available in two versions, i.e.

electrically powered and tractor-powered (540 rpm

on the p.t.o. shaft).

Crop

6. Fan

7. Venturi

8. Scoop elevating section

9. Aspiration chamber

10. Outlet, cleaned grain

Light impurities

Small impurities

Large impurities

Loading...

Loading...