37

Malting barley sorting

In the sorting of malting barley the small-sized

grains are separated on the outer screen.

Considerably larger quantities are to pass through

the outer screen when sorting malting barley than in

ordinary pre-cleaning of grain. In the sorting of

malting barley it is therefore normally the capacity

of the outer screen that determines the capacity of

the combi-cleaner.

In the sorting of malting barley the impurities from

screens and aspiration cleaner are asually kept

apart, as it is not desirable that the small grains mix

with the impurities from the aspiration cleaner.

Therefore remove the covering plate from the outlet

of the trough auger.

Use, for instance, a Kongskilde TRL blower with a

venturi to disharge the small grains.

Sorting

Basic sorting of commercial malting barley is nor-

mally based on 90 % grains exceeding 2.5 mm.

This has also been assumed in the following.

Before starting to sort the malting barley it is advan-

tageous to know the sorting of the starting material

(the unsorted grain). This may be determined

manually by means of Kongskilde's test screens or

you can ask a feedstuff dealer to test one or more

samples.

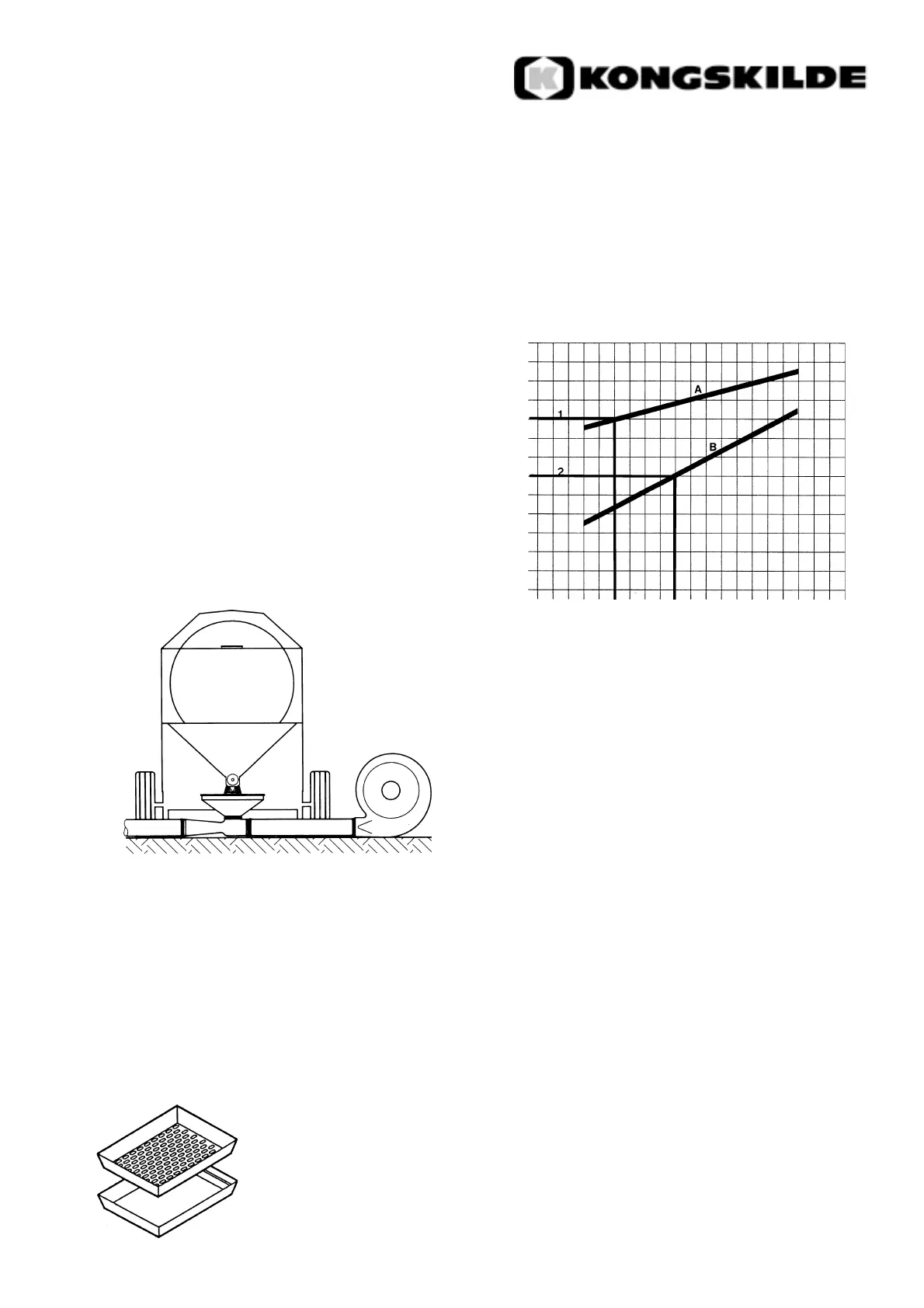

Test screen

with slots

Bottom scren (without

slots - for collection

of small-sized grains)

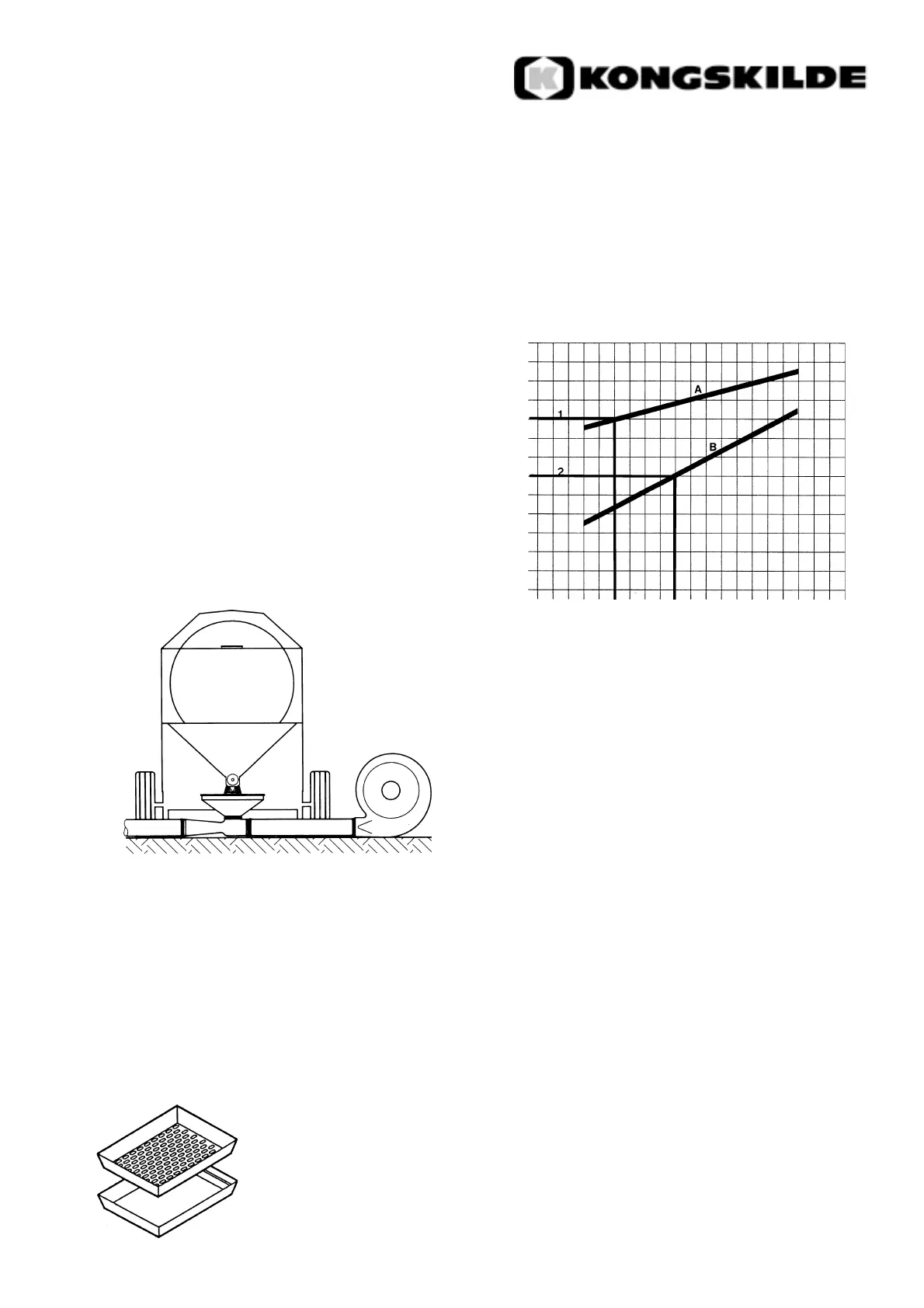

Based on the sorting of the grain and the outer

screen used the diagram overleaf will show the

capacity required to obtain a final sorting result of

90 % grains exceeding 2.5 mm

Recommended capacities for malting barley

sorting

(A) Screen 2.5 x 16.5

(B) Screen 2.65 x 16.5

The recommended capacities are subject to the

following conditions:

Final sorting result:................................ 90 % grains

exceeding 2,5 mm

Moisture content:.......................... Max. 14 % (Well-

threshed malting barley)

Inclination of combi-cleaner: ................................ 5°

Examples:

1. Starting material sorting: ................... 82 %

Desired final sorting: ......................... 90 %

Outer screen slots: ............................ 2.5 x 16.5

Recommended capacity

according to graph: ........................... 5 t/h

2. Starting material sorting: ................... 76 %

Desired final sorting: ......................... 90 %

Outer screen slots: ............................ 2.65 x 16.5

Recommended capacity

according to graph: ........................... 9 t/h

If the starting material sorting is lower than the

curve of the outer screen used, this means that two

cycles will be required to reach a final sorting result

of 90 %.

Starting material sorting %

Capacity (t/h)

90

88

86

84

82

80

78

76

74

72

70

68

66

64

0 2 4 6 8 101214161820

Loading...

Loading...