17

Operation - Drilling and Driving

Pocket-HoleScrews

For best results, follow these guidelines when drilling and driving pocket-hole screws:

■ Use the correct screw size according to this chart:

Gauged Material

Thickness

Easy-Set

Stop Collar

Material Thickness

Setting

Screw Length

1/2 Range 1/2

Automatic

1" (25 mm)*

3/4 Range 3/4 1-1/4" (32 mm)

3/4 1-1/2" (38 mm)

1-1/2 Range 1½ 2-1/2" (64 mm)

* A 1" screw is recommended for most applications, but if your workpiece

is on the low end of the range, a 3/4" screw might be required to keep

the screw tip from protruding.

Note If your material thickness falls in the range, use the same setup

techniques as the 3/4" range with a 1-1/2" screw. For more information on screw

selections, go to www.Kregtool.com/Screws or simply scan the QR code on the

side of your sample screw package.

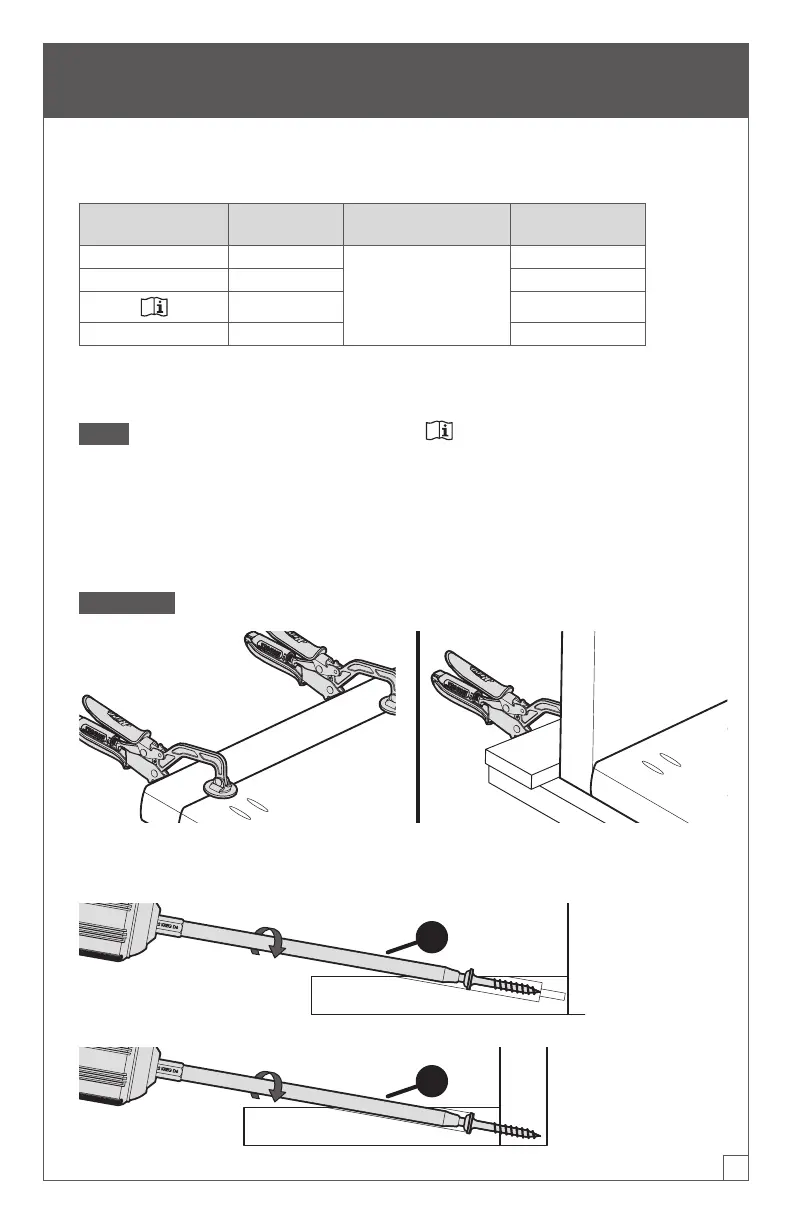

■ Clamp joints in place to ensure a better nished joint. These examples show face

joints and edge joints.

WARNING When drilling, always ensure that the workpiece is clamped securely.

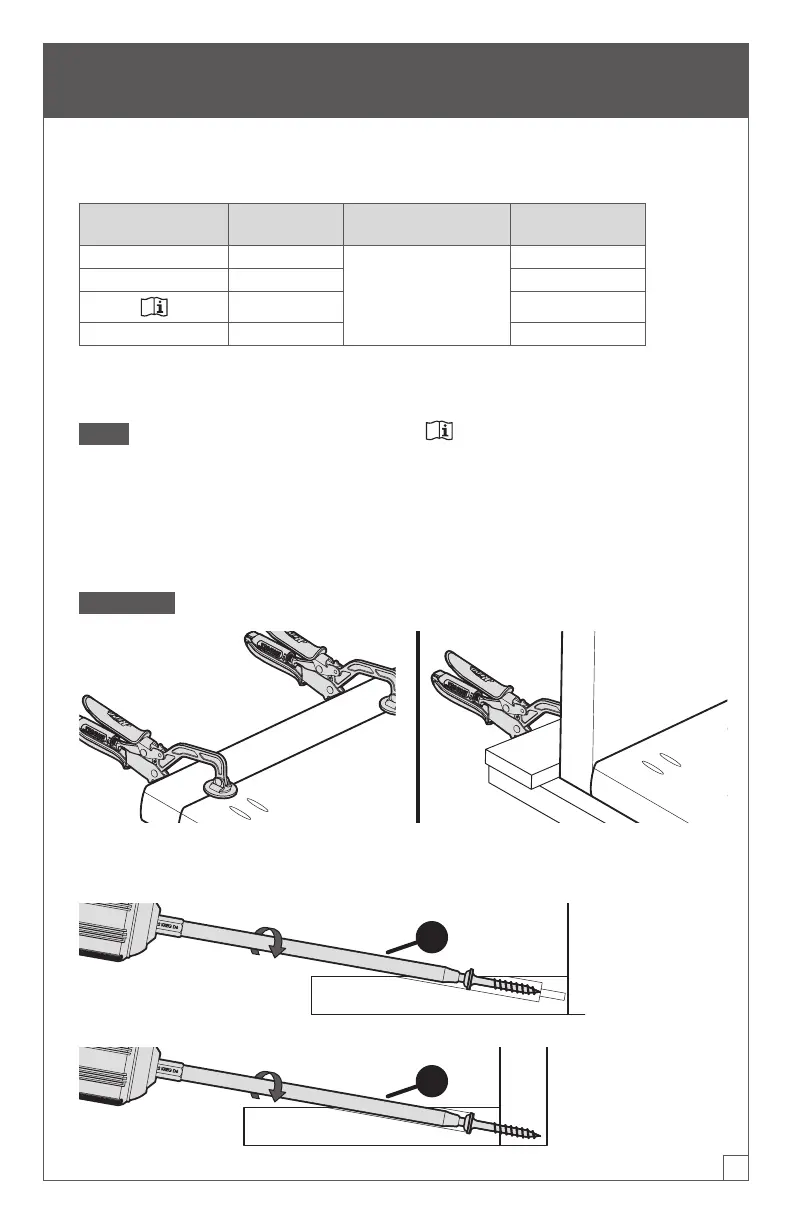

■ Place your screw on the driver tip (E), position the screw in the pocket hole, and

drive the screw until it is fully seated without overdriving.

E

E

Loading...

Loading...