7.1.1.3.1 Open-loop control mode using external standard signal

By default, analog input 1 (terminal P7:9 AnIn1 and 10 AGND P7) is set as the

setpoint source (

3-5-4-1

). A direct voltage of 0 to 10 V (0 to 100 %) is expected as the

signal. If a current signal, e.g. 4 - 20 mA (0 - 100 %) is to be used, the Anln1 Setting

parameter (

3-8-2-1

) has to be set to Current. The setpoint input can be adapted to

the signal by using the parameters

3-8-2-2

to

3-8-2-5

. At a setpoint ≤ 50 %,

PumpDrive always operates at a minimum frequency of 25 Hz (

3-6-1-2

: 50 %) set in

the factory. If the setting range of the setpoint signal is to apply from the minimum

frequency (

3-6-1-2

) on, the AnIn 1 Low parameter (

3-8-2-7

) has to be set to 50 % and

the corresponding unit.

At analog input 1, a setpoint of 78 % is to be set via a 0 - 10 V voltage signal. 7.8 V

then corresponds to a speed of 39 Hz (

3-11-4-1

maximum output frequency = 50 Hz)

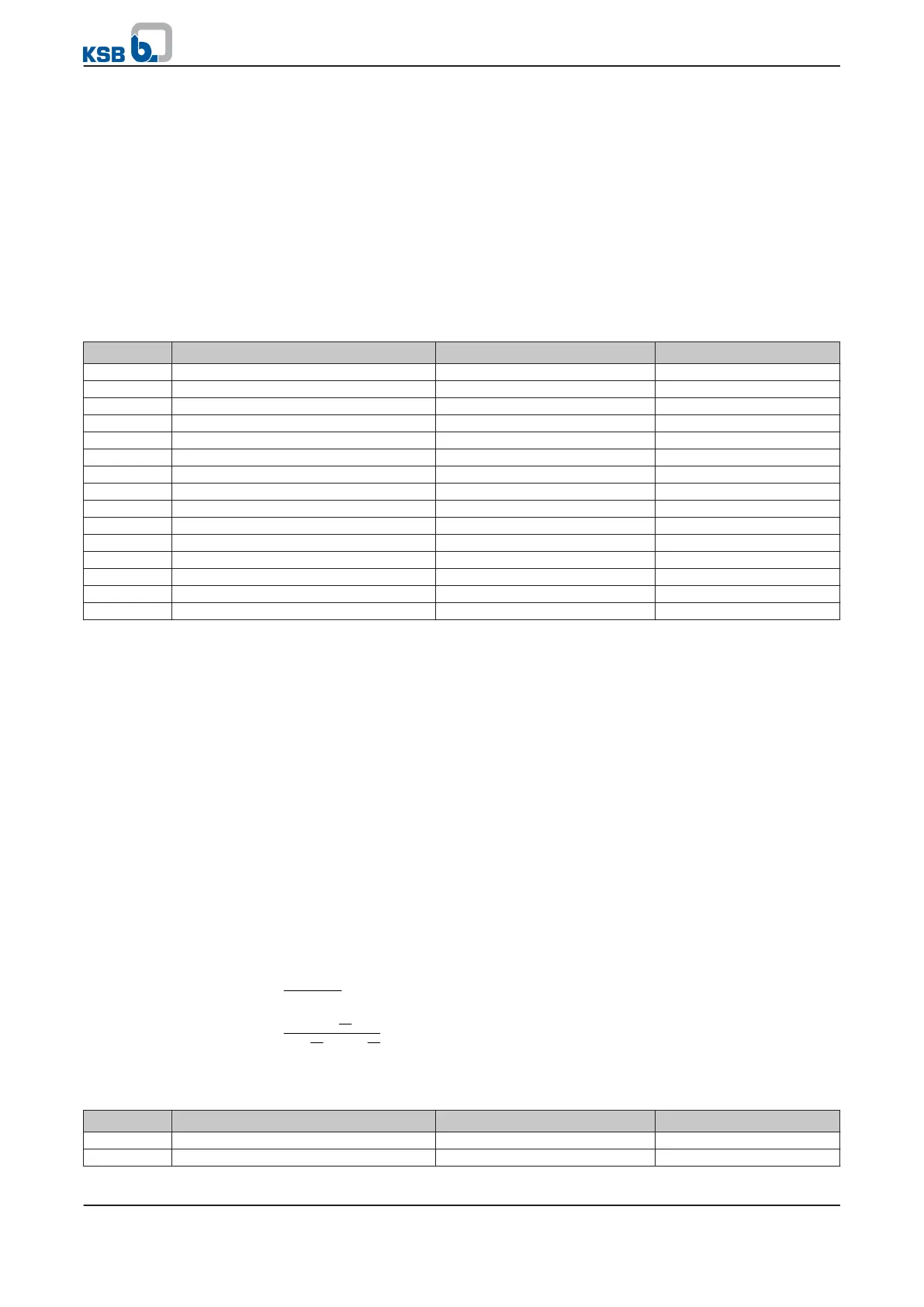

Table 50: Sample parameterisation of analog input 1

Parameter Description Settings Factory setting

3-2-2-1

Setpoint unit % %

3-2-2-3

Pressure unit % %

3-5-1-2

Minimum setpoint 0 0

3-5-1-3

Maximum setpoint 100 100

3-5-4-1

Setpoint source 1 Analog IN 1 Analog IN 1

3-5-4-2

Setpoint source 2 None Configurable Setpoint

3-5-4-3

Setpoint source 3 None Remote Setpoint

3-8-2-1

AnIn 1 setting Voltage Current

3-8-2-2

Analog IN 1 Low voltage 0 0

3-8-2-3

Analog IN 1 High voltage 10 10

3-8-2-6

Unit of Analog IN 1 % %

3-8-2-7

Low value for Analog IN 1 0 0

3-8-2-8

High value for Analog IN 1 100 100

3-9-1-1

PI mode Disabled Disabled

3-9-1-6

PI Auto Deactivated Activated

Maintain the following sequence for deactivating the process controller:

1.

Change parameter

3-9-1-6

.

2. Change parameter

3-9-1-1

.

⇨ The value displayed for parameter

1-3-1-3

Setpoint is 78 %.

7.1.1.3.2 Open-loop control mode via control panel

Graphical control panel

The speed setpoint can be specified using the control panel. For this purpose, the

Setpoint Source 2 parameter

(3-5-4-2)

must be set to Configurable Setpoint (factory

setting).

The setpoint is specified using the Configurable Setpoint parameter

(3-5-2-1)

. The

setpoint unit is set using the Setpoint Unit

(3-2-2-1)

and Max Setpoint

(3-5-1-3)

parameters (⇨ Section 7.1.1.2 Page 49) .

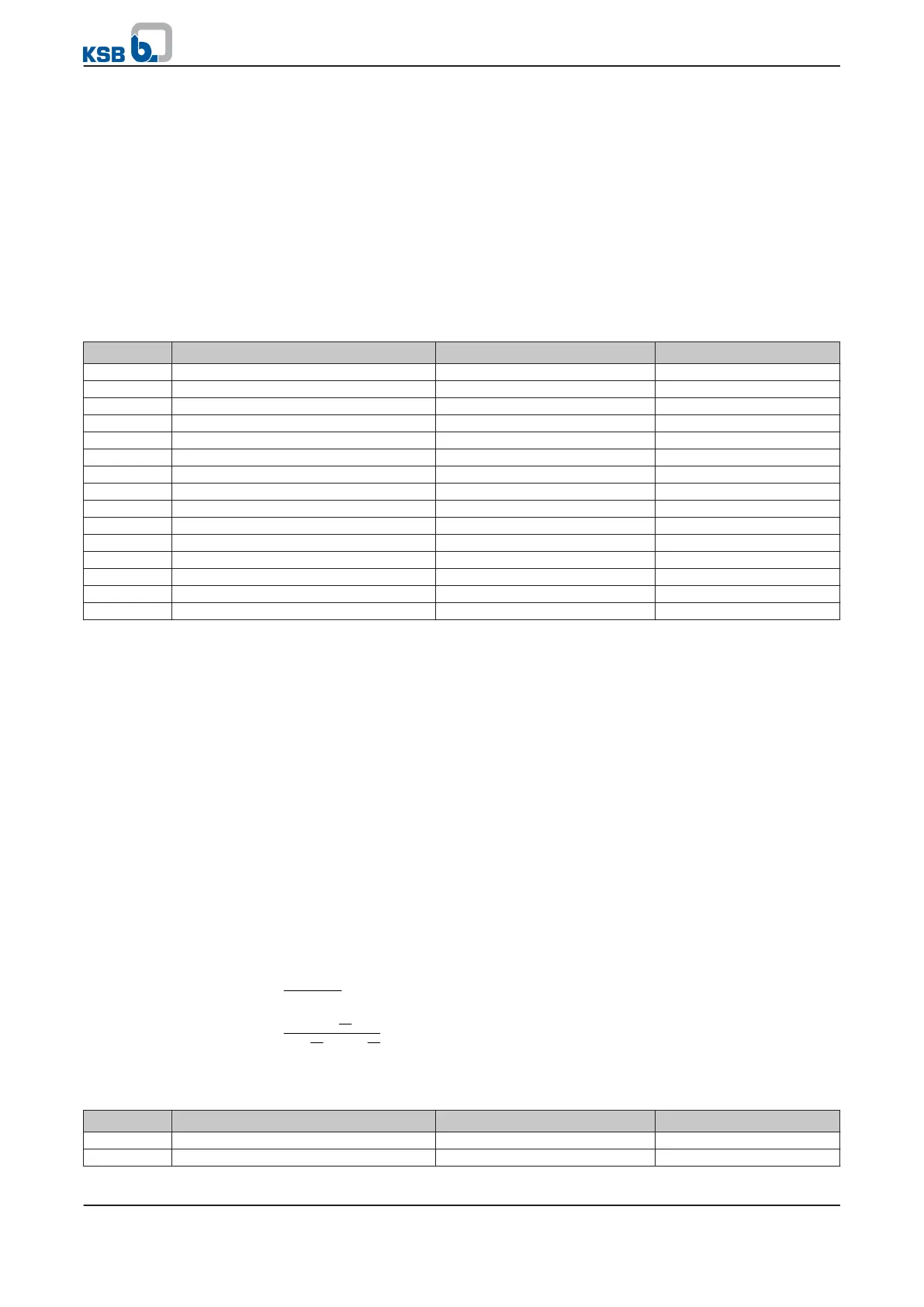

A 2-pole motor is to run with a speed of 2500 rpm. This corresponds to a frequency

of 41.67 Hz. A setpoint of 83.33 % must be set at the control panel for this purpose.

(for

3-11-4-1

maximum output frequency = 50 Hz)

n

n

-

n

(

-

)

= [%]

2500

1

3000

1

- 1500

1

(

100% - 50%

)

= 83,33%

Target

Target

Target

Target

Max.

Max.

Min.

Min.

Min.

Min.

Min.

Fig. 26: Sample calculation

Table 51: Sample parameterisation of open-loop control mode via control panel

Parameter Description Settings Factory setting

3-2-2-1

Setpoint unit % %

3-2-2-3

Pressure unit % %

Example

Example

7 Commissioning/shutdown

52 of 162

PumpDrive

Loading...

Loading...