KTR Kupplungstechnik

GmbH

D-48407 Rheine

ROTEX

®

GS

Operating/mounting instructions

KTR-N

Sheet:

Edition:

45510 EN

22of36

15

Please note protection

mark ISO 16016.

Drawn: 15.10.12 Pz Replaced for: KTR-N valid from 08.02.12

Verified: 29.10.12 Pz Replaced by:

Assembly of Clamping Hubs

2.6, 2.8,2.9, 7.5, 7.6, 7.8 and

The power transmission of ROTEX

®

GS clamping hubs (types 2.0, 2.5, 2.8, 7.5 and 7.8) is done frictionally

engaged. With types 2.1, 2.6, 2.9, 7.6 and 7.9 a feather key additionally provides for positive locking power

transmission.

The following process should be noted for the assembly:

• Clean and degrease the hub bore and the shaft.

• Slightly detach the clamping screw.

• Slip the hub onto the shaft. Please observe the dimension l

1

/l

2

.

• Tighten the clamping screws at the tightening torques mentioned in table 3.

For types 2.8, 7.5, 7.8 or 2.9, 7.6, 7.9 (with keyway) the screws have to be

tightened alternately at the tightening torques mentioned in table 3.

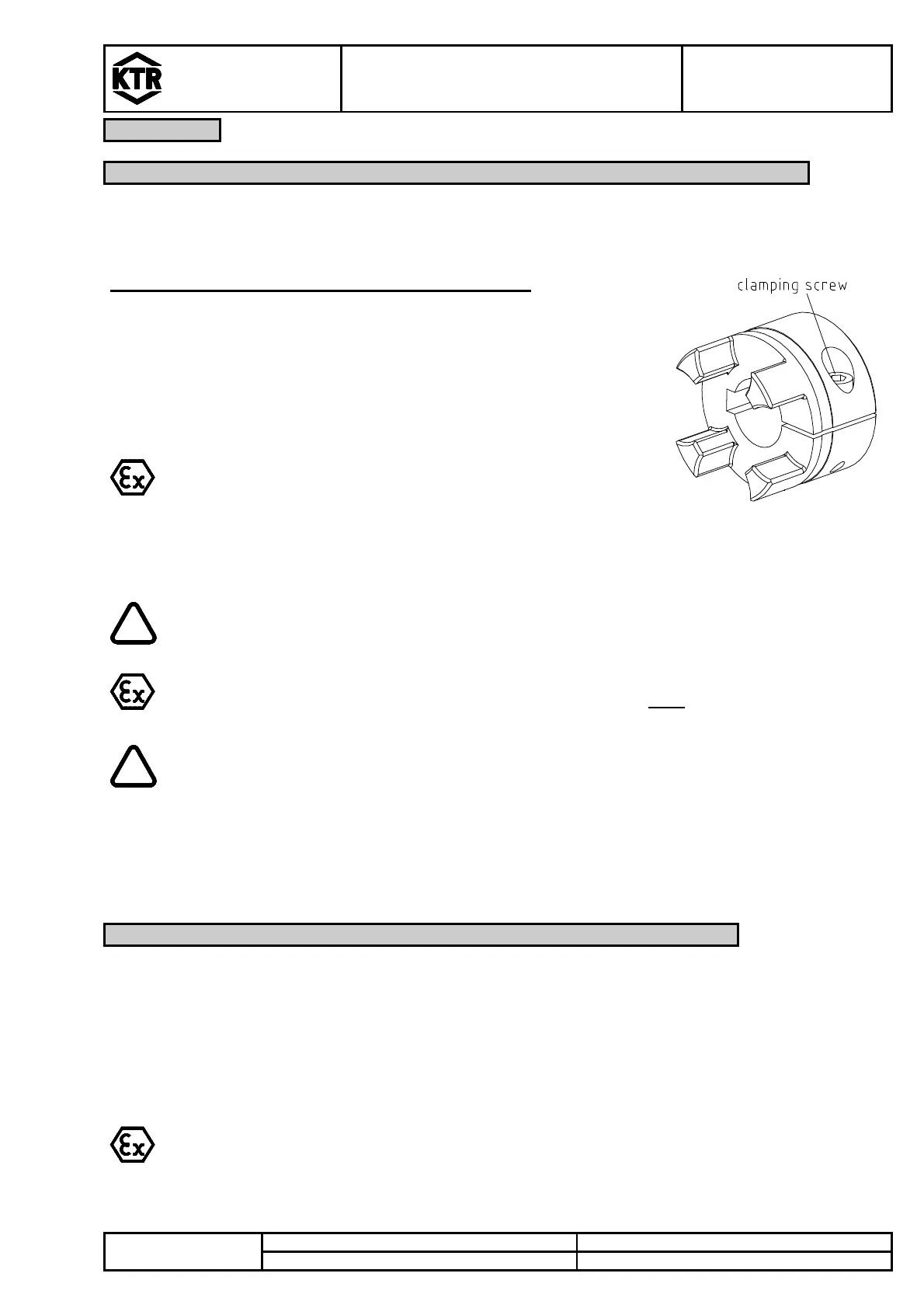

Illustration 21: Assembly clamping hub

Please note: types 2.8, 2.9, 7.5, 7.6, 7,8

or 7.9 have 2 clamping screws

For the applications in hazardous areas the setscrews to

fasten the hubs as well as all screw connections have to be

secured against self-slackening additionally, e. g. by glueing

with Loctite (medium-tight).

The frictionally engaged transmittable torques of the clamping hubs depend on the bore

diameter.

Hub types 2.0, 2.5, 2.8, 7.5 and 7.8 (without feather key) may only be used in category 3 and

are not permissible for applications according to DIN EN ISO 13849, part 2.

If the clamping screws are not tightened at the correct tightening torque, there is the danger

of

a) a fracture of the hub and plastic deformation with a too high tightening torque T

A

b) type 6.0: a fracture of the hubs/cams and plastic deformation with a too high tightening

torque T

A

c) an early slippling, untightening of the screws with a too small tightening torque T

Assembly of Clamping Ring Hubs

The power transmission of ROTEX

®

GS clamping ring hubs is frictionally engaged. The necessary surface

pressure is transmitted via the clamping ring with internal taper to the taper hub and consequently to the shaft.

The torques mentioned in tables 5 to 7 take into account a combination of fit H7/k6 from Ø55 G7/m6. With a

higher backlash of fit the torques mentioned in tables 5 to 7 are reduced.

The stiffness and dimensions of the shafts (here specifically hollow shafts) have to be selected in a way that

sufficient safety against plastic deformation is ensured. This may roughly be reviewed as per the following

criterion.

For the use in hazardous areas the setscrews/capscrews and setscrews to fasten the hubs

additionally have to be secured against slackening, e. g. by conglutinating with Loctite

(average joint strength).

Loading...

Loading...