KTR Kupplungstechnik

GmbH

D-48407 Rheine

ROTEX

®

GS

Operating/mounting instructions

KTR-N

Sheet:

Edition:

45510 EN

23of36

15

Please note protection

mark ISO 16016.

Drawn: 15.10.12 Pz Replaced for: KTR-N valid from 08.02.12

Verified: 29.10.12 Pz Replaced by:

Assembly of Clamping Ring Hubs

For clamping connections with hollow shafts the

required internal diameter of the hollow shaft d

iW

is

calculated based on the following formula:

[ ]

mm

R

p2R

dd

2,0p

W2,0p

iW

⋅−

⋅≤

Shearing stress on the internal shaft diameter for

hollow shaft:

2

2

W

W

tiW

mm/N

C1

p2

−

⋅

−≈σ

Shearing stress for solid shaft:

2

WtW

mm/Np−=σ

R

= proof stress of shaft material [Nmm

] d

= internal diameter of hollow shaft [mm]

p

= surface pressure hub/shaft [N/mm

] d = shaft diameter [mm]

C

= d

/ d

The required strength does not exist if the hollow shaft bore is bigger than the max. internal bore calculated or if

the shearing stress exceeds the yield strength of the material. For a detailed calculation please contact the KTR

engineering department.

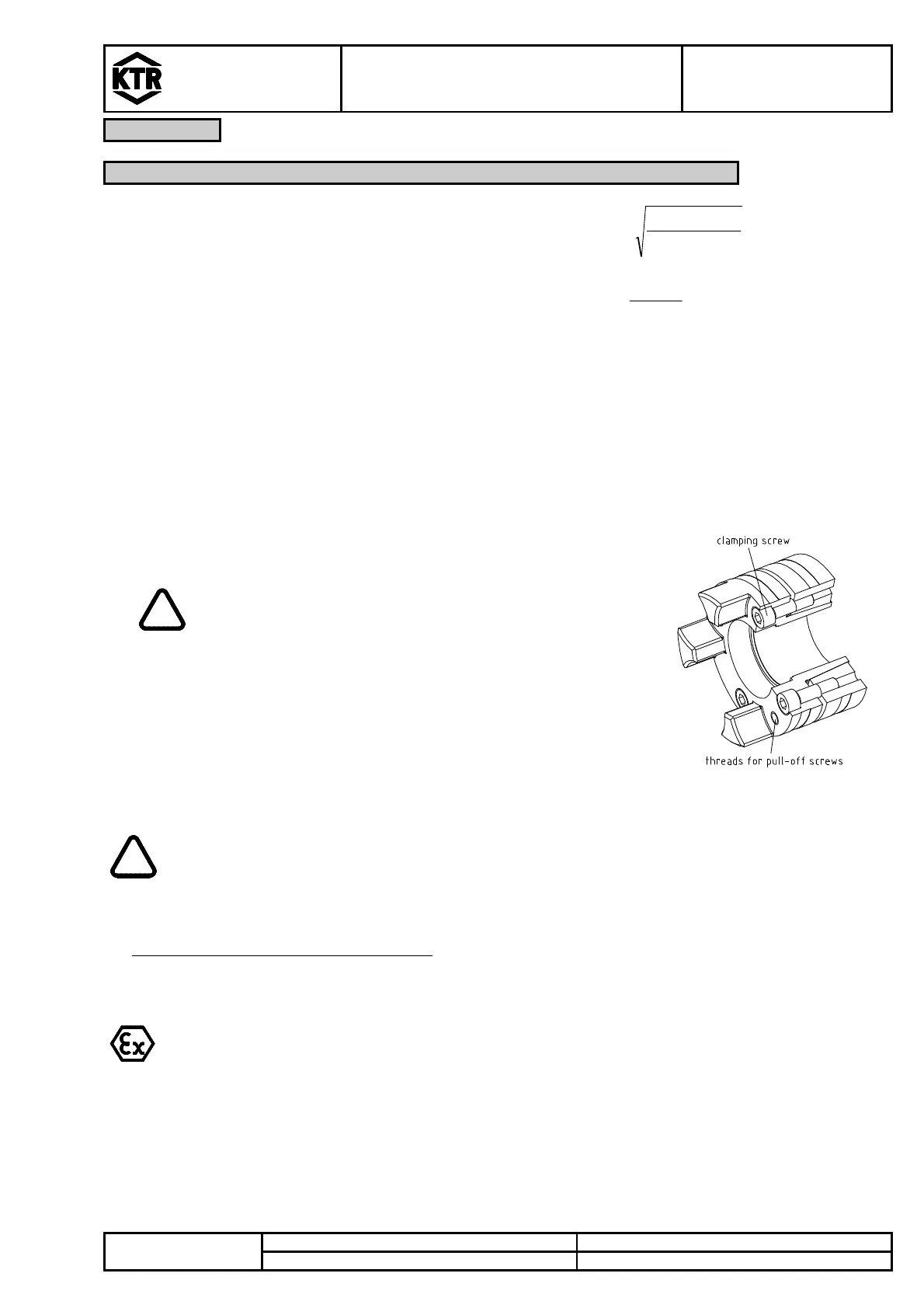

• Clean the hub bore and shaft and review for dimensional accuracy,

afterwards lubricate with a thin-bodied oil (e. g. Castrol 4 in 1 or

KlüberQuietsch-Ex).

Illustration 22: Assembly of

clamping ring hub with clamping ring

Oils and greases containing molybdenum disulfide or

other high-pressure additives as well as internal

lubricants must not be used.

• Slightly detach the clamping screw and pull the clamping ring from the hub

only marginally to make sure that the clamping ring is loosened.

• Slip the clamping ring hub onto the shaft. The dimension L

3

should be

adhered to at least.

• Tighten the clamping screws evenly stepwise and crosswise to the

tightening torque mentioned in table 6 or 7. This process has to be

repeated until the tightening torque is reached for all clamping screws.

If the clamping screws are not tightened at the correct tightening torque, there is the danger

of

a) a fracture of the hub and plastic deformation with a too high tightening torque T

A

b) an early slipping, untightening of the screws with a too small tightening torque T

• Assembly of the clamping ring hub 6.0 light:

Tighten the clamping screws evenly stepwise and crosswise at 1/3 or 2/3 tightening torque T

A

, respectively

(see table 5) until the ring gets in contact. Afterwards tighten the screws at the tightening torque mentioned in

table 5 one after another.

For the applications in hazardous areas the setscrews to fasten the hubs as well as all

screw connections have to be secured against self-slackening additionally, e. g. by glueing

with Loctite (medium-tight).

Selection of clamping hubs

With the use in explosion-proof areas the clamping hubs have to be selected in a way that

the difference between the peak torque of the machine including all operation parameters

and the frictionally engaged torque of the clamping hub is at least a service factor of s = 2.

Loading...

Loading...