KTR Kupplungstechnik

GmbH

D-48407 Rheine

ROTEX

®

GS

Operating/mounting instructions

KTR-N

Sheet:

Edition:

45510 EN

6of36

15

Please note protection

mark ISO 16016.

Drawn: 15.10.12 Pz Replaced for: KTR-N valid from 08.02.12

Verified: 29.10.12 Pz Replaced by:

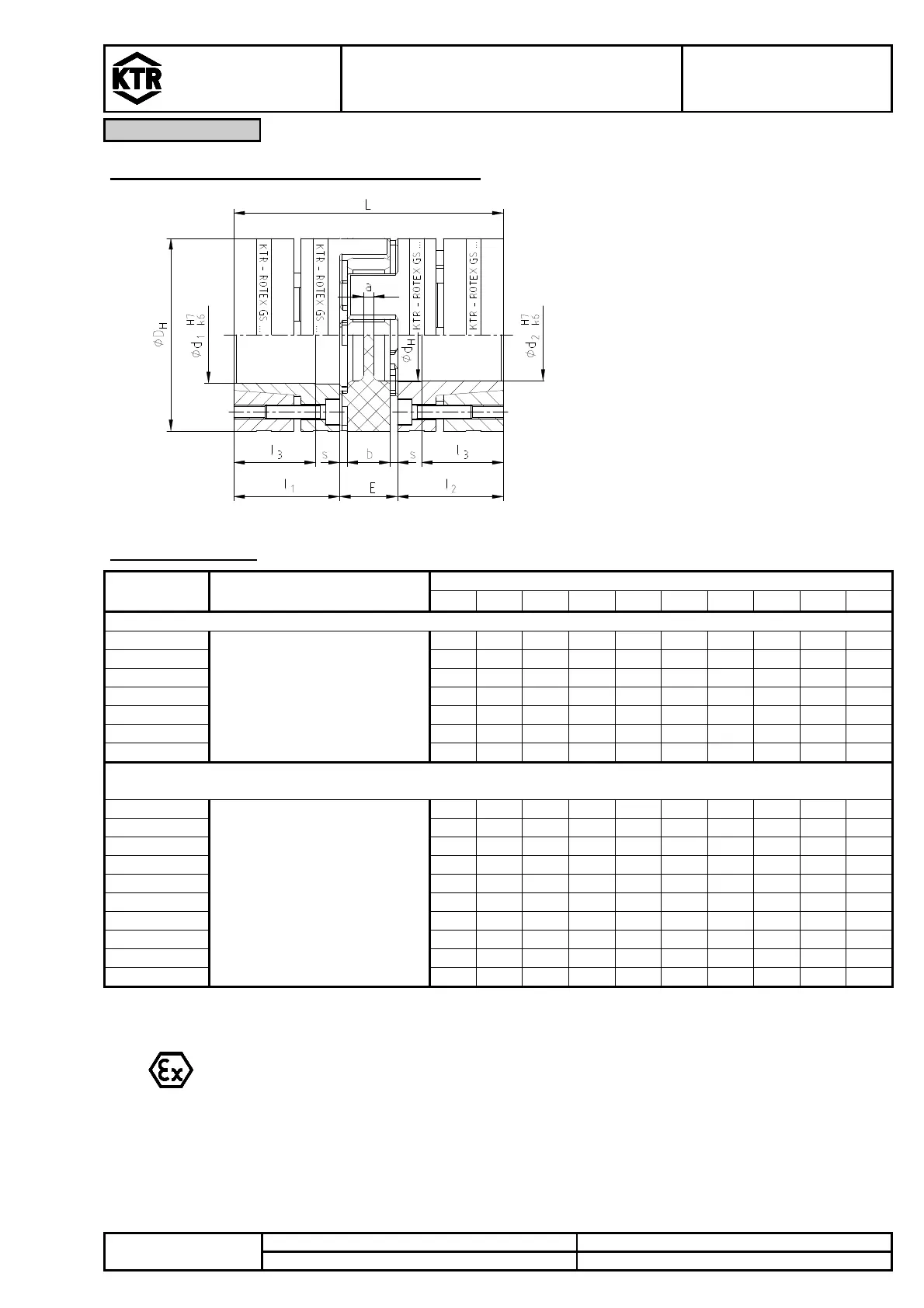

Clamping ring hubs 6.0, 6.0 steel and 6.0 light

Pull-off thread M

1

between clamping screws.

Illustration 5: ROTEX

®

GS clamping ring hubs

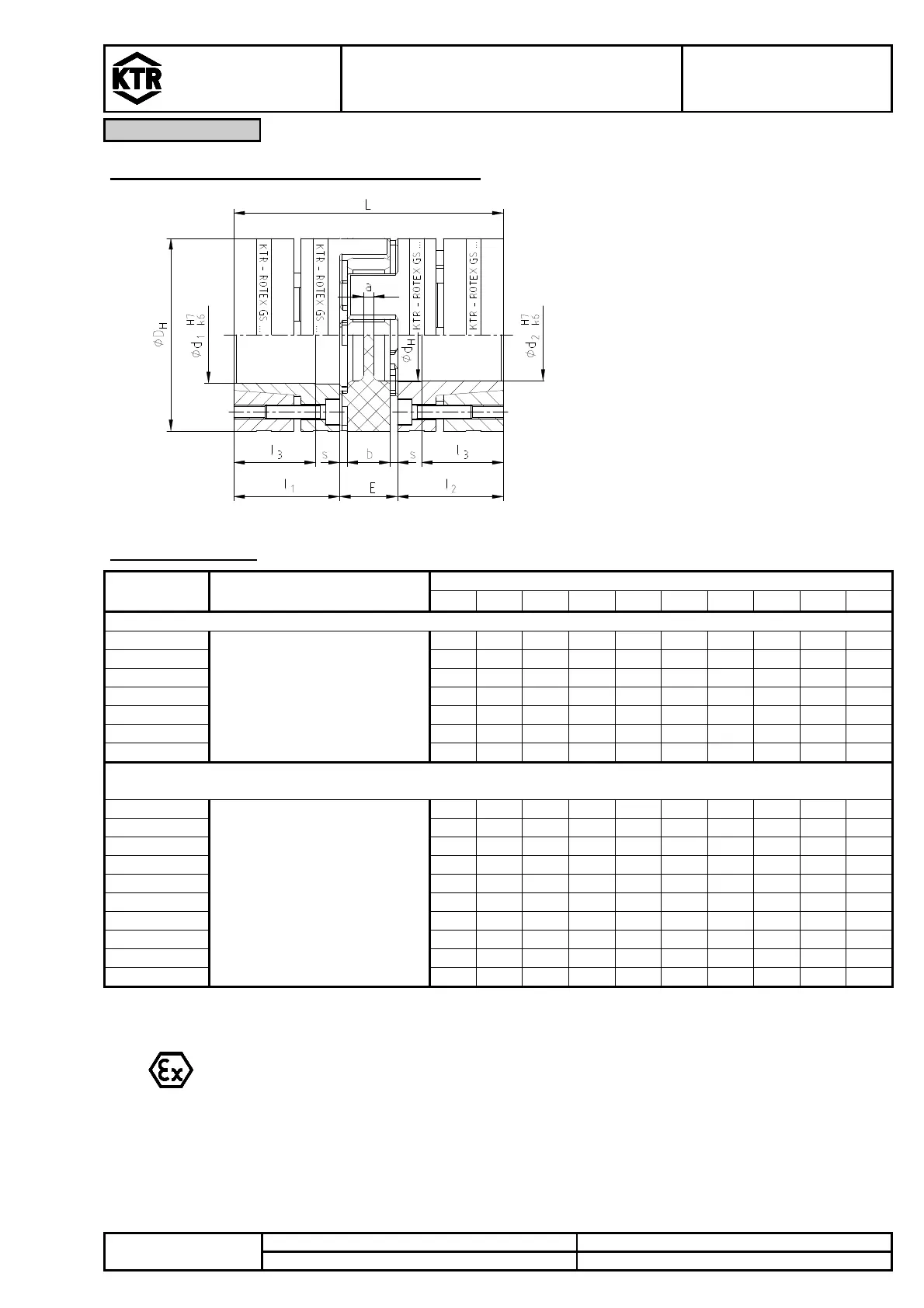

Table 4:Dimensions

Size

Spider (part 2)

Torques [Nm]

Dimensions [mm]

D

d

L l

; l

l

E b s a M

Hub/Clamping ring material - Aluminium (Al-H)

14

Figures see

table 2

30 10,5

50 18,5

13,5

13 10 1,5

2,0

M3

19 40 18 66 25 18 16 12 2,0

3,0

M4

24 55 27 78 30 22 18 14 2,0

3,0

M5

28 65 30 90 35 27 20 15 2,5

4,0

M5

38 80 38 114

45 35 24 18 3,0

4,0

M6

42 95 46 126

50 35 26 20 3,0

4,0

M8

48 105

51 140

56 41 28 21 3,5

4,0

M10

6.0 (size 14 – 38)

Hub and clamping ring material - Steel (St-H)

Hub material – Aluminium (Al-H)/clamping ring material – steel (St-H)

19

Figures see

table 2

40 18 66 25 18 16 12 2,0

3,0

M4

24 55 27 78 30 22 18 14 2,0

3,0

M5

28 65 30 90 35 27 20 15 2,5

4,0

M5

38 80 38 114

45 35 24 18 3,0

4,0

M6

42 95 46 126

50 35 26 20 3,0

4,0

M8

48 105

51 140

56 41 28 21 3,5

4,0

M10

55 120

60 160

65 45 30 22 4,0

4,5

M10

65 135

68 185

75 55 35 26 4,5

4,5

M12

75 160

80 210

85 63 40 30 5,0

5,0

M12

90 200

104

245

100

75 45 34 5,5

6,5

M16

1) For coupling selection please see ROTEX

®

GS catalogue.

Please note transmittable torques of clamping connections (see table 5 to7)

2) ØD

H

+ 2 mm with high speeds for expansion of spider

3)

For the applications in hazardous areas the setscrews to fasten the hubs as well as all

screw connections have to be secured against self-slackening additionally, e. g. by

glueing with Loctite (medium-tight).

Subject to the increased safety with the assembly (several screws are tightened) and the high

friction torque of the clamping ring hub, this type is permissible for applications according to

DIN EN ISO 13849, part 2.

Loading...

Loading...