KTR Kupplungstechnik

GmbH

D-48407 Rheine

ROTEX

®

GS

Operating/mounting instructions

KTR-N

Sheet:

Edition:

45510 EN

7of36

15

Please note protection

mark ISO 16016.

Drawn: 15.10.12 Pz Replaced for: KTR-N valid from 08.02.12

Verified: 29.10.12 Pz Replaced by:

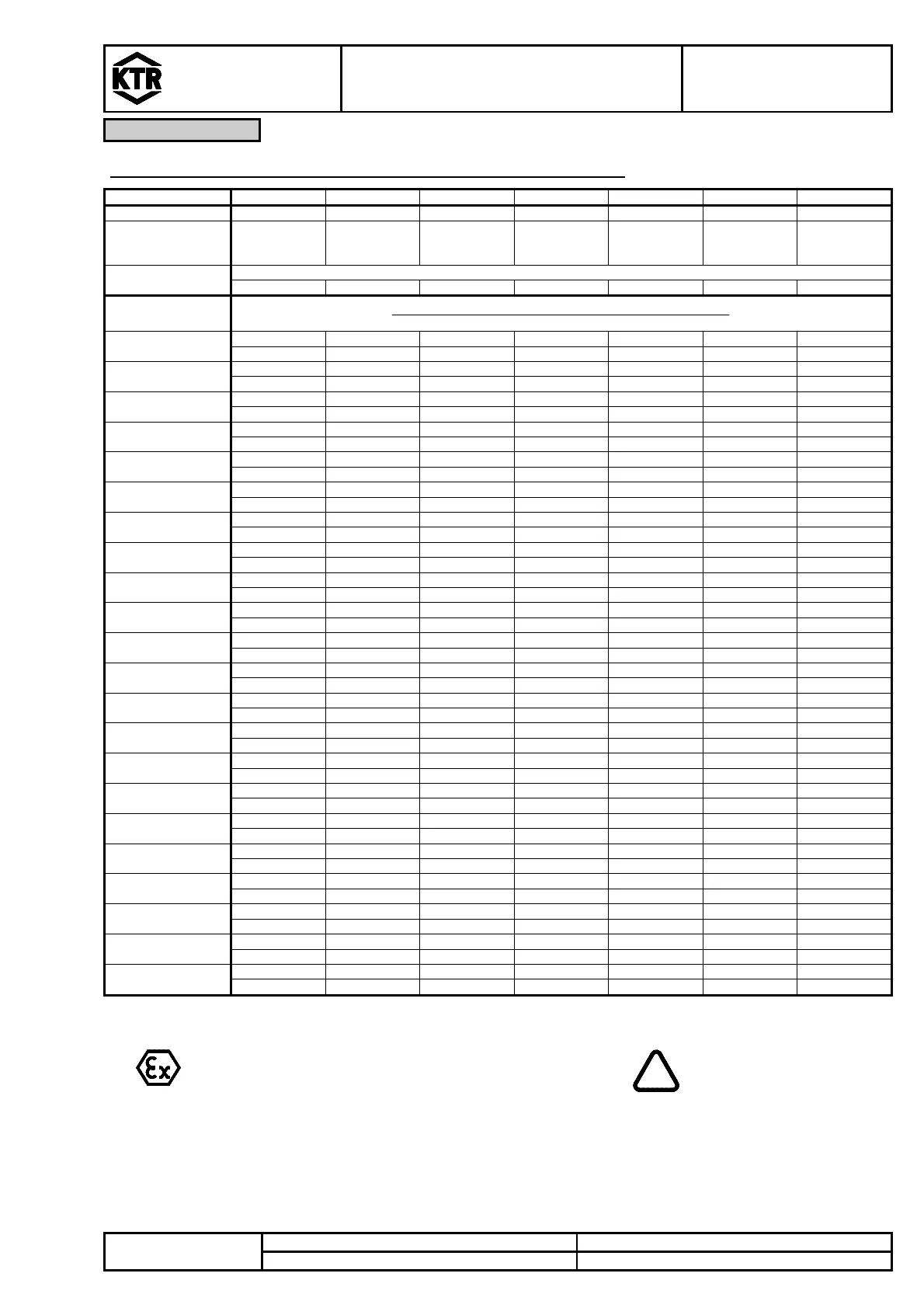

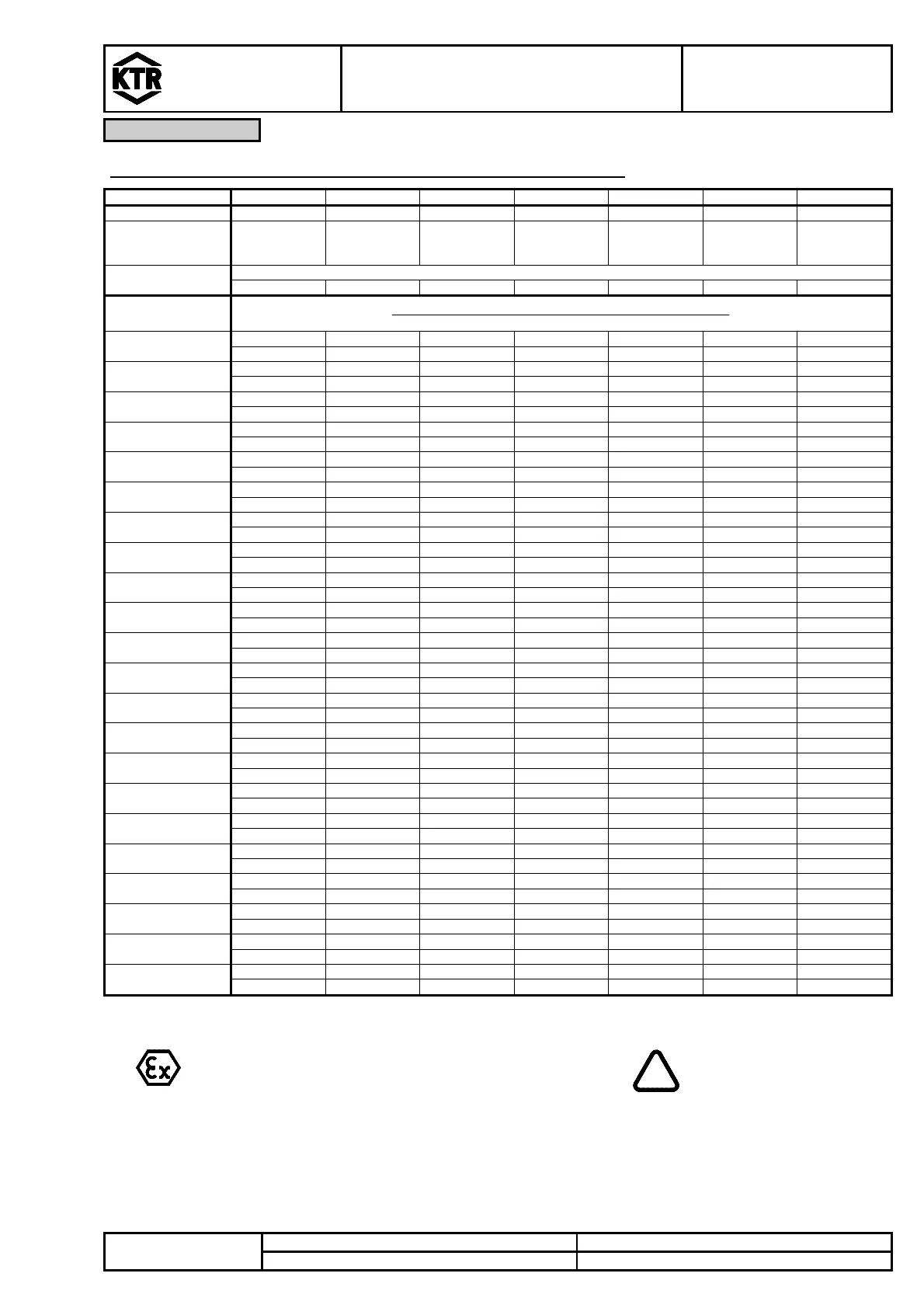

Table 5: Torques and surface pressure of clamping ring hubs 6.0 light

Size 14 19 24 28 38 42 48

Clamping screw M

M3 M4 M5 M5 M6 M8 M10

Number z

(for each clamping

ring hub)

4 6 4 8 8 4 4

Tightening torque

T

A

[Nm]

Hub/Clamping ring material – Aluminium (Al-H)

1,34 3 6 6 10 25 49

Bore Ø d

1

Transmittable torque of clamping ring hub [Nm]

Surface pressure [N/mm

2

]

Ø6

5,4

49,4

Ø10

7,5 17

39,3 65,9

Ø11

11,3 20

49,7 67,3

Ø14

24,5 41 47

57,6 87,9 80,6

Ø15

49 57

92,5 85,3

Ø16

36 67 99

55,3 89,4 102

Ø19

56 98 145

64 96,6 109

Ø20

64 110 133 203

67 99 88 102,9

Ø22

135 165 252

102,8 92,4 107

Ø24

127 201 304

76,3 95,7 110

Ø25

139 219 331

77,9 97 110,2

Ø28

175 248 394 444

81,5 86,9 104,9 113,6

Ø30

285 452 508 572

88,6 106,3 114,8 108

Ø32

253 453 535 638

66,5 91 103,5 107,2

Ø35

307 543 638 762

69,3 93,2 105,4 108,9

Ø38

329 550 692 842

63,6 78,4 95 100

Ø40

609 763 929

79,5 95,8 101,1

Ø42

669 754 943

80,3 83,4 91

Ø45

634 858 1074

63,6 84,6 91,9

Ø48

964 1208

85,2 92,3

Ø50

976 1136

79 77,3

Ø55

1336

77,4

The transmittable torques of the clamping connection consider the max. clearance with bore H7/k6 shaft fit.

The torque is reduced in case of bigger fit clearance.

1)

For the applications in hazardous areas the setscrews to fasten the

hubs as well as all screw connections have to be secured against

self-slackening additionally, e. g. by glueing with Loctite (medium-

tight).

An calculation is necessary if

hollow shafts are used!

Loading...

Loading...