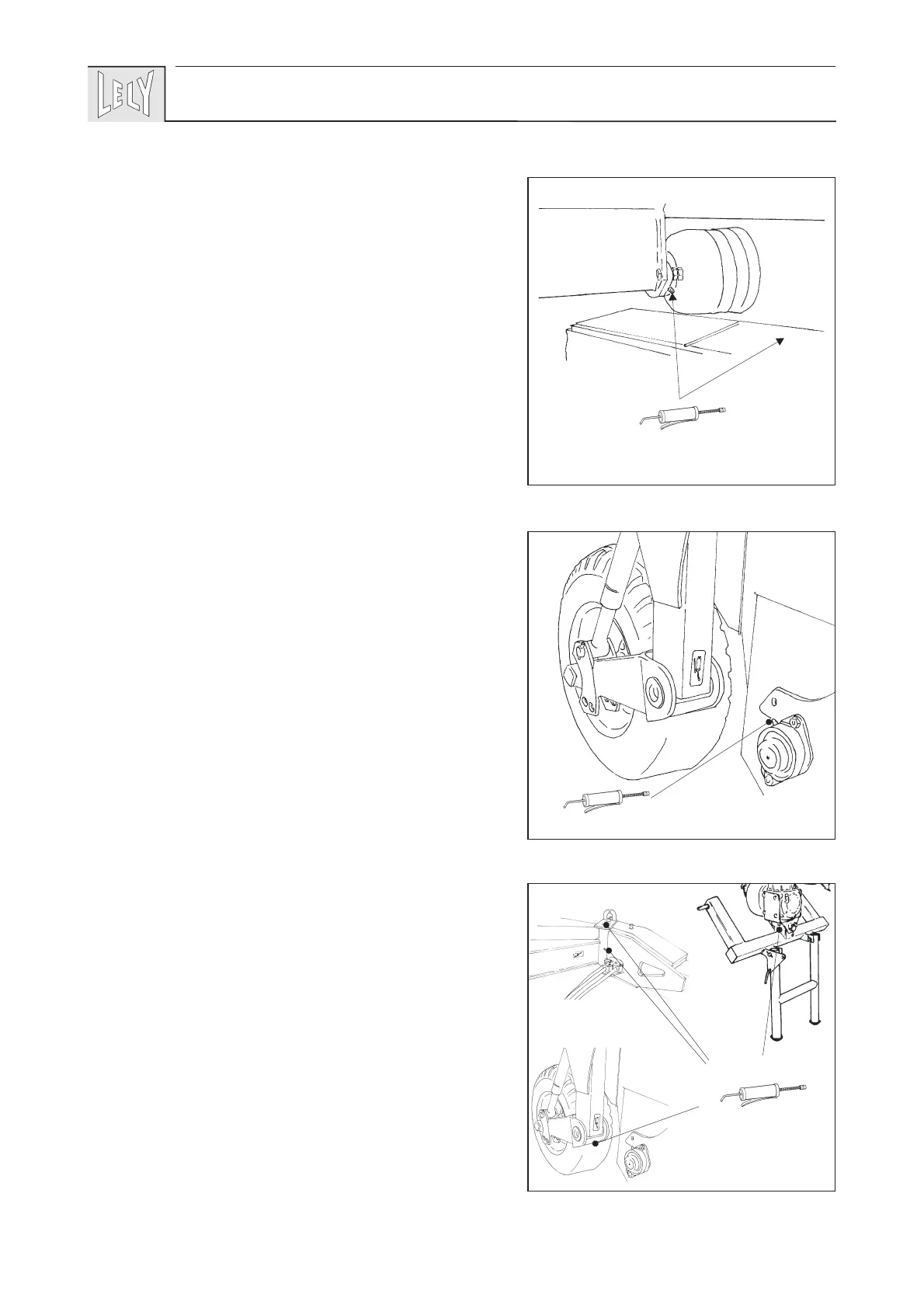

- Grease the bearing blocks of the intermediate shaft in the

drawbar every 8 working hours (fig. 19).

- Grease the bearing blocks of the conditioner rotor every 8

working hours (fig. 20).

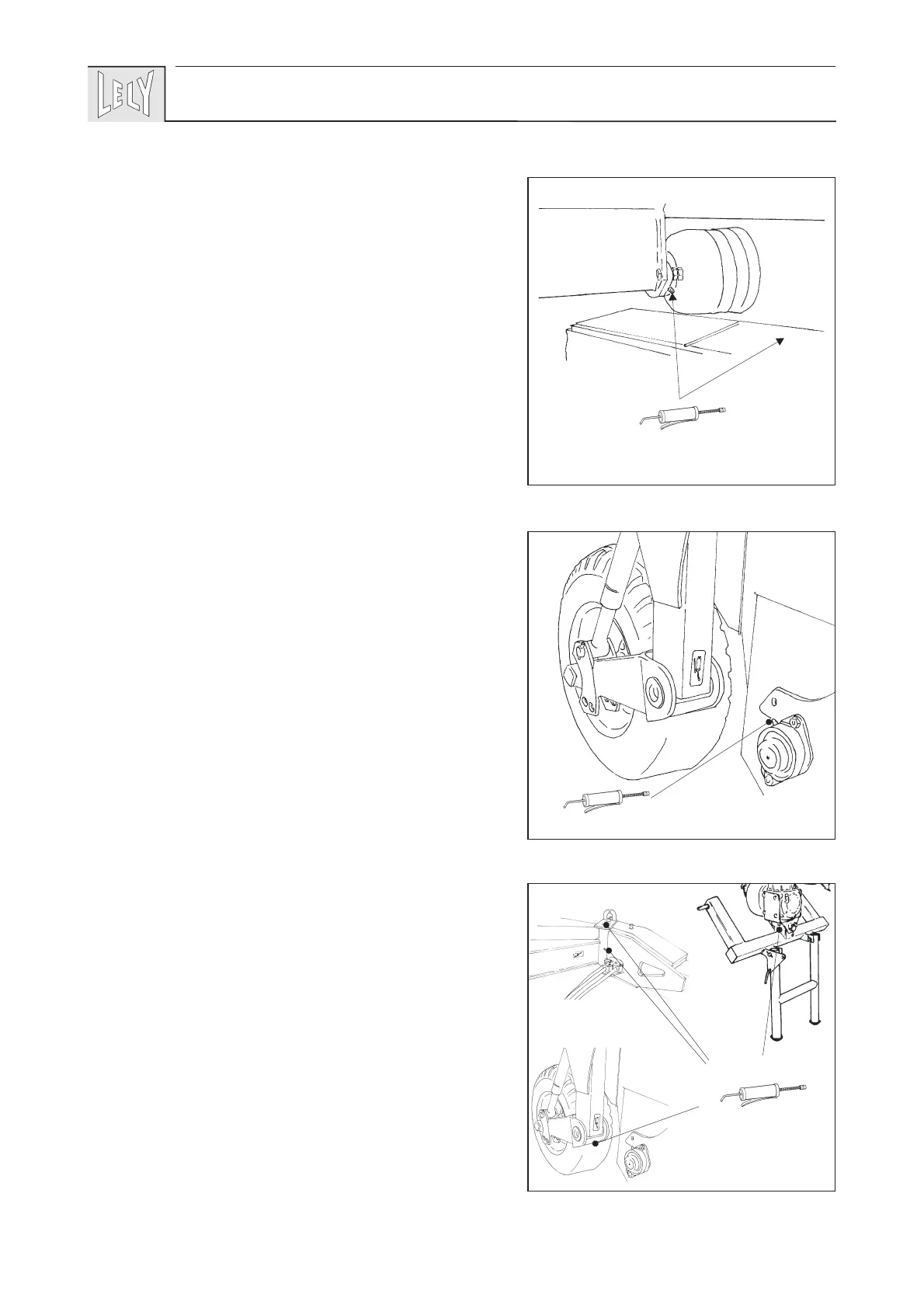

- Grease or lubricate all remaining pivot points every 40

working hours.

- Grease the pivot point (A, fig. 21) of the headstock every

40 working hours.

- Grease the pivot point (B) of the drawbar every 40 working

hours.

- Grease the pivot point (C) of the wheel supports every 40

working hours.

7.3

Intermittent maintenance

Intermittent maintenance has to be carried out:

• at the start of the haymaking season

• before prolonged storage of the machine

• when the machine is used extensively during the

season.

- Grease all points of the machine listed in chapter 7.2

“Lubrication”.

- Grease the spring-loaded locking pins of the yoke lock of

the PTO shaft.

- Check if the PTO shaft telescopes smoothly. A damaged

PTO shaft may cause excessive wear and tear to the

machine and tractor.

- Check the machine for damage and flaws.

- Check the gearboxes for oil leakage. For more detailed

information concerning gearbox servicing, please refer to

chapter 7.5 “Change of oil in gearbox”.

- Check the condition of wear plates, mower discs and

knives. For more detailed information concerning mower

knives, please refer to chapter 7.3 “Replacement of

knives”.

34

19

8 h

20

8 h

21

AB

C

40 h

Loading...

Loading...