Commissioning

Using the keypad XT EMZ9371BC − Vector control

7

EDK82EV113 DE/EN/FR 8.1

139

L

Vector control optimisation

In general, the vector control is ready for operation after the motor parameters have been

identified. Vector control must only be optimised for the following drive performance: −32−

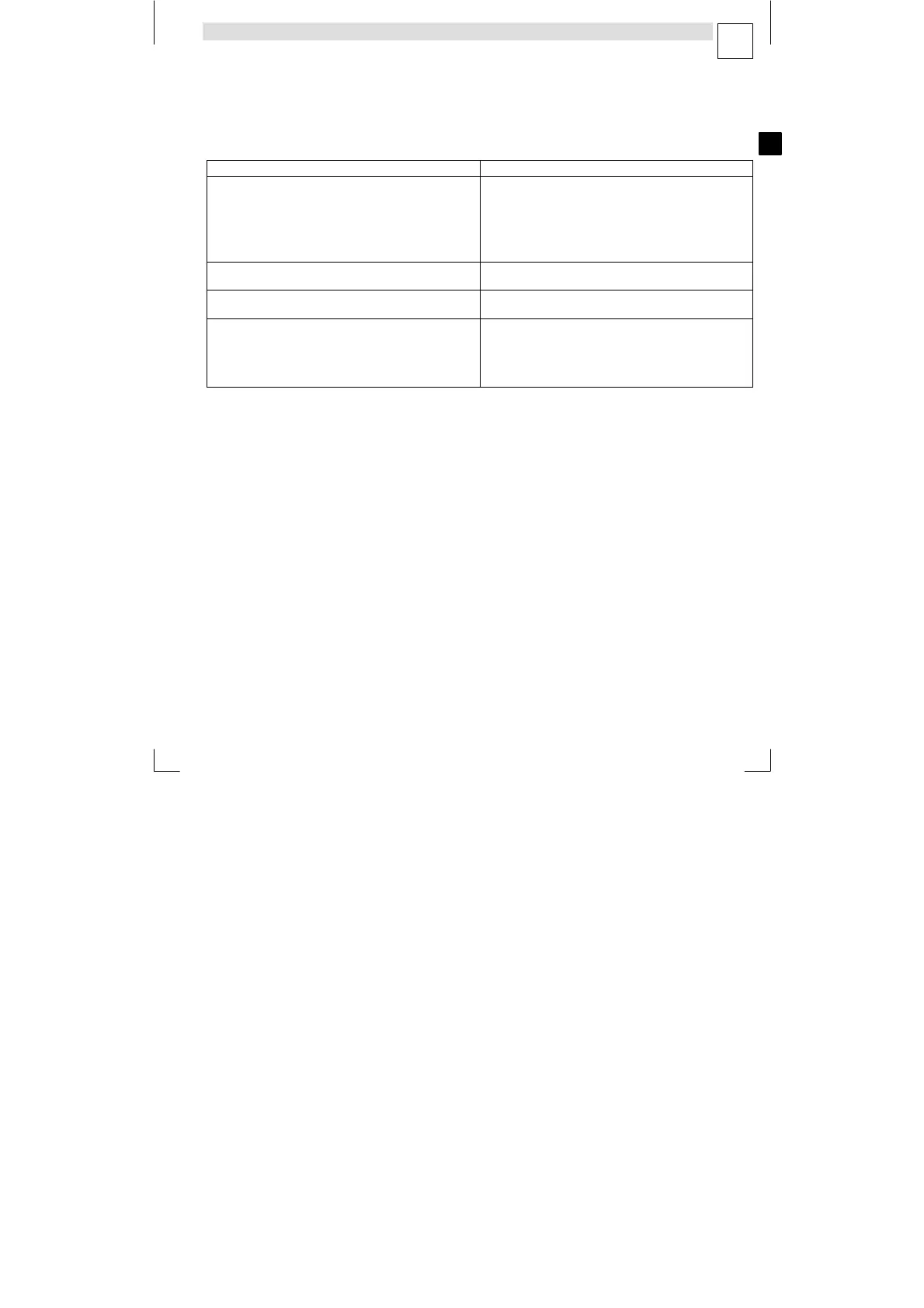

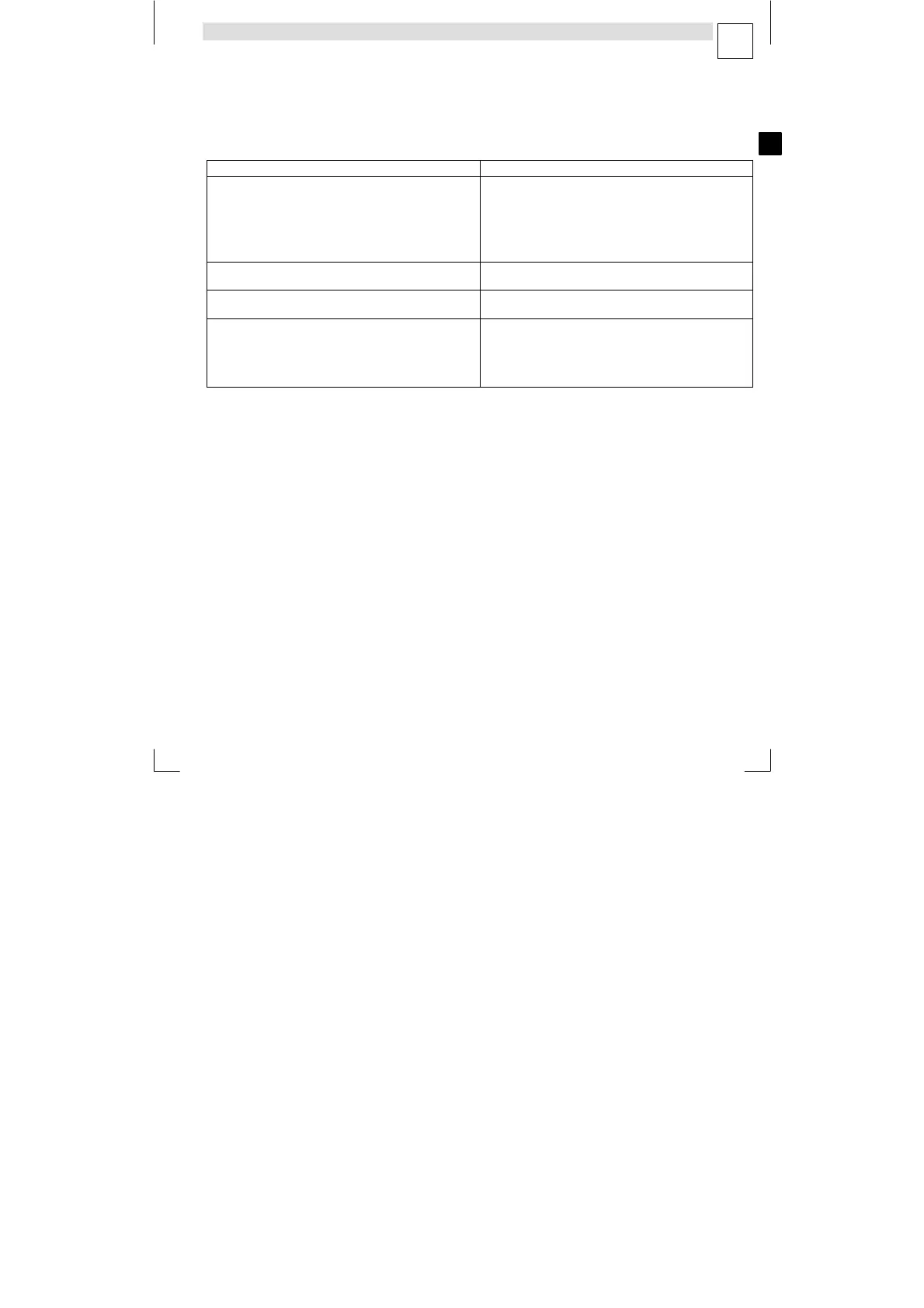

Drive performance Remedy

Rough motor run and motor current (C0054) > 60 % rated motor

current in idle running (stationary operation)

1. Reduction of motor inductance (C0092) by 10 %

2. Check of motor current under C0054

3. If the motor current (C0054) > 50 % rated motor current:

– C0092 must be reduced until the motor current amounts to

50 % of the rated motor current

– Reduce C0092 by max. 20 %!

Torque too low for frequencies f < 5 Hz (starting torque) Increase of motor resistance (C0084) or increase of motor

inductance (C0092)

Poor constant speed at high loads (setpoint and motor speed are

not proportional).

Increase of slip compensation (C0021)

Overcompensation results in drive instability!

Error messages OC1, OC3, OC4 or OC5 during acceleration times

(C0012) < 1 s (drive controller is no longer able to follow the

dynamic processes)

Change readjustment time of the I

max

controller (C0078):

l Reduction of C0078 = I

max

controller becomes quicker (more

dynamic)

l Increase of C0078 = I

max

controller becomes slower

("smoother")

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...