Do you have a question about the Lenze 9300 vector Series and is the answer not in the manual?

Explains how to navigate and understand the System Manual, detailing the information provided.

Provides essential safety and application guidelines for Lenze controllers, including operational risks and compliance.

Covers safety aspects for Lenze motors, including handling, installation, electrical connection, and operation.

Details potential dangers and hazards associated with the controller during operation and parameter setting.

Details the rated electrical data for 400 V mains voltage operation under normal conditions for various 9300 vector types.

Provides guidelines for selecting cable cross-sections and protection measures on AC and motor sides, including DC supply.

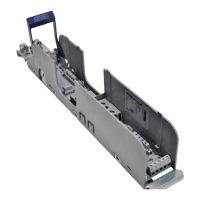

Covers installation methods for basic devices, including mounting with fixing rails, thermally separated mounting, and cold plate technique.

Details installation procedures for basic devices, including important notes, mounting with fixing brackets, and thermally separated mounting.

Provides installation guidance for basic devices, covering important notes, mounting with fixing brackets, and thermally separated mounting.

Explains installation methods for basic devices in the 75-90 kW range, including important notes and mounting with fixing brackets.

Covers crucial general notes for wiring, including protection of persons, device protection, cable length, motor protection, and supply conditions.

Details fundamental principles for wiring to ensure Electromagnetic Compatibility, covering shielding, mains/DC connections, motor/control cables, and installation practices.

Provides a critical checklist of pre-commissioning checks for wiring, system functions, motor configuration, and parameter settings.

Details step-by-step examples for parameter setting using the XT EMZ9371BC keypad for both V/f characteristic and vector control modes.

Covers the process of adjusting the motor parameters, including entry of motor data, motor selection, temperature monitoring, and current limits.

Provides detailed instructions on using the XT EMZ9371BC keypad for parameter setting, including general data, installation, display elements, and saving/transferring parameters.

Describes various function blocks used for configuration, including Diameter Calculator, Master Frequency inputs/outputs, and Motor Control.

Guides on identifying and analyzing errors using controller LEDs, keypad status information, and the history buffer for fault analysis.

Provides a systematic approach to eliminating common errors, including maloperation, clamp operation, overvoltage, and specific error messages.

Highlights the 'safe standstill' function's purpose, its compliance with safety standards, and requires additional safety instructions and functional tests.

Loading...

Loading...