Wiring the standard device

Basics for wiring according to EMC

Installation in the control cabinet

5

5.2

5.2.5

5.2-4

EDSVF9333V EN 3.0-06/2005

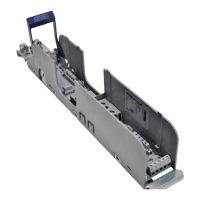

5.2.5 Installation in the control cabinet

ƒ Only use mounting plates with conductive surfaces (zinc-coated or

V2A-steel).

ƒ Lacquered mounting plates are not suitable even if the lacquer is

removed from the contact surfaces.

ƒ Ensure a large-surface connection of several mounting plates (e.g.

using earthing strip).

ƒ Connect controller, filters, and chokes to the earthed mounting plate

with a wire of large a cross-section as possible:

ƒ The motor cable is perfectly installed if

– it is routed separately of mains cables and control cables,

– it crosses mains cables and control cables only at a right angle,

ƒ Cables must be routed close to the mounting plate (reference

potential) as freely suspended cables act like aerials.

ƒ Cables must be routed in a straight line to the terminals (avoid “tangle

of cables”).

ƒ Use separate cable ducts for power cables and control cables. Do not

mix up different cable types in one cable duct.

ƒ Minimise coupling capacitances and inductances due to unnecessary

cable lengths and reserve loops.

ƒ Short-circuit unused cores to the reference potential.

ƒ Route the positive and negative cables for DC 24 V together over the

total l ength to prevent loops.

ƒ Connect all components (drive controller, choke, filter) to a central

earthing point (PE rail).

ƒ Create an earth system in star connection.

ƒ Comply with the corresponding minimum cable cross-sections.

Mounting plate requirements

Mounting of the components

Optimum cable routing

Connection system of

earthing

Loading...

Loading...