EDS94TA10040xxxx EN 1.1 - 10/2008 L 27

9400 Technology applications | Synchronism with mark synchronisation

Parameter setting & configuration

Machine parameters

O Tip!

Setting the cycle (C03938) only is required if the selection "Modulo" is set as

traversing range (C02528).

For operation with a virtual master the following setting of the gearbox ratio is

recommended to achieve a good resolution of the guiding angle/master value:

• Numerator (C03930) = 100

• Denominator (C03931) = 1

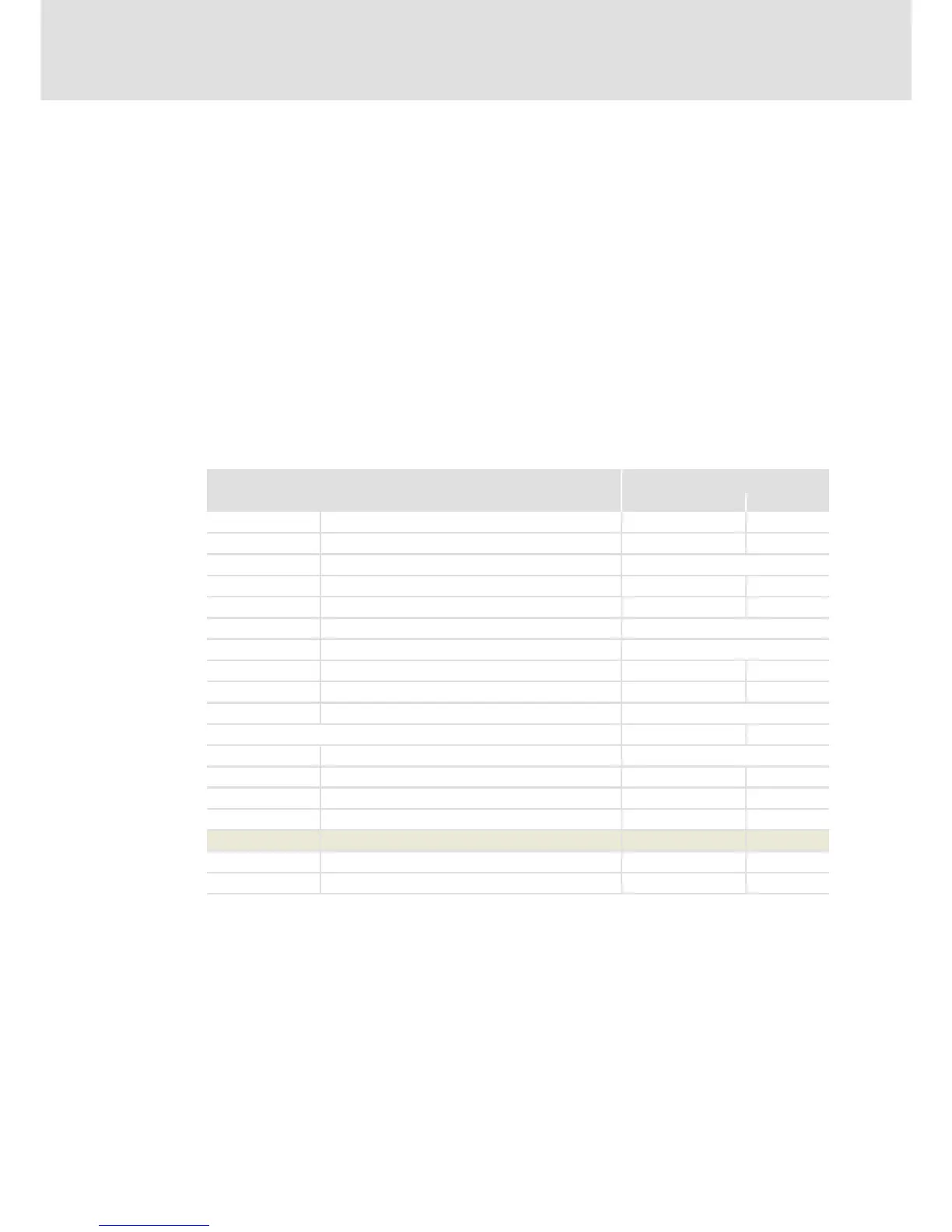

4.3.2 Slave axis (machine axis)

Among other things, the following machine parameters describe the motor end of the

mechanics used.

r Parameter setting: Tab Application parameters dialog level Overview Synchronism

Machine parameters

Parameter Lenze setting

Value Unit

C00173 Mains voltage 400/415 V

C00174 Undervoltage (LU) threshold 285 V

C00600 Resp. to DC bus overvoltage Trouble

C02520 Gearbox factor numerator: Motor 1

C02521 Gearbox factor denom: Motor 1

C02527 Motor mounting direction Motor rotating CW

C02570 Position control structure Position control

C02522 Gearbox factor num.: Pos. enc. 1

C02523 Gearbox factor denom.: Pos. enc. 1

C02529 Mounting direction of position encoder Encoder rotating CW

Description of the mechanics (load, tool)

C02528 Traversing range Modulo

C02524 Feed constant 360.0000 unit

C02525 Unit °

C02526 User-defined unit °

C02533 Time unit s

C00273/1 Motor moment of inertia Motor-dependent kg cm

2

C00273/2 Load moment of inertia 0.00 kg cm

2

Loading...

Loading...