21

ENGLISH

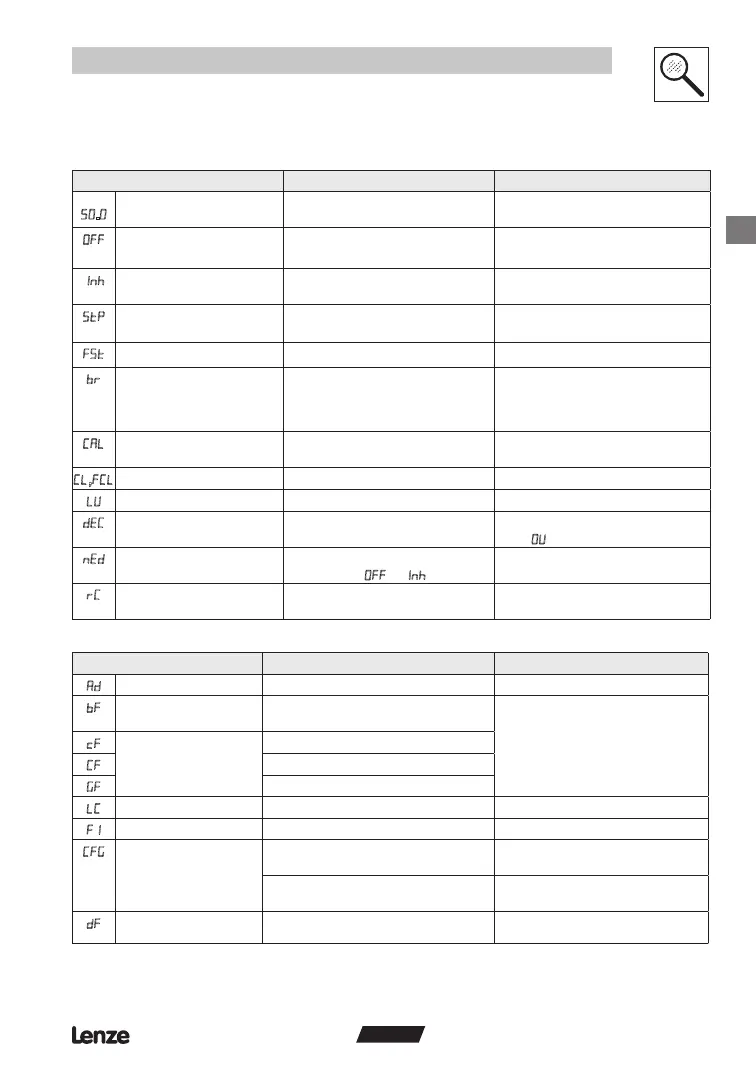

Troubleshooting and fault elimination

(1) The drive can only be restarted if the error message has been reset; see c70

Status Cause Remedy

e.g.

Present output frequency Trouble free operation

O

Stop

(outputs U, V, W inhibited)

LOW signal at terminal 28 Set terminal 28 to HIGH

1

Inhibit

(outputs U, V, W inhibited)

Controller is set up for remote

keypad or serial control (see C01)

Start the controller via the remote

keypad or serial link

Output frequency = 0 Hz

(outputs U, V, W inhibited)

Quick stop activated through digital

input or serial link

Deactivate Quick stop

Flying restart attempt c42 = 2, 3

DC-injection brake active DC-injection brake activated

• via digital input

• automatically

Deactivate DC-injection brake

• digital input = LOW

• automatically after holding time c06

has expired

L

Motor calibration is in process c48 = 1 and terminal 28 = HIGH Only perform the motor calibration

when C14 = 4...7

Current limit reached Controllable overload Automatically (see C22)

Undervoltage on DC bus Mains voltage too low Check mains voltage

Overvoltage on DC bus during

deceleration (warning)

Excessively short deceleration time

(C13, c03)

Automatically if overvoltage

< 1 s, U, if overvoltage > 1 s

No access to code Can only be changed when the

controller is in or

Set terminal 28 to LOW or inhibit by

serial link

Remote keypad is active Attempt to use buttons on front of

controller

Buttons on front of controller are

disabled when remote keypad is

active

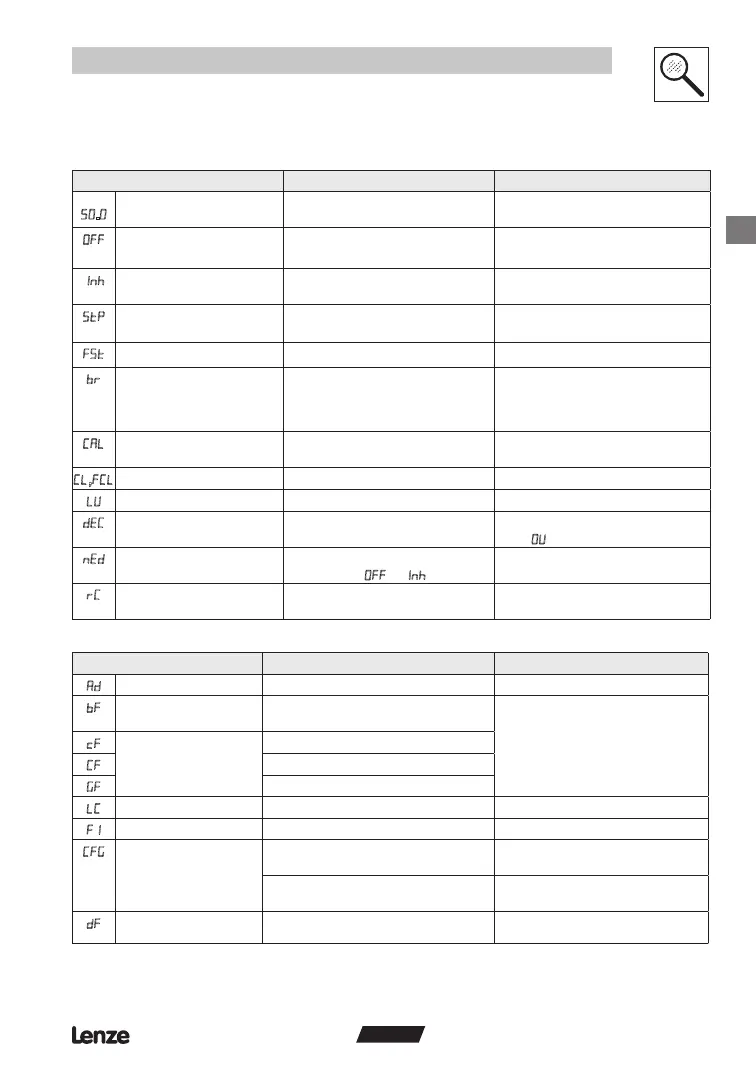

Error Cause Remedy

(1)

A/D converter error Please contact Lenze

Identication fault C93 value stored on EPM does not match

controller model

• Use EPM providing valid data

• Load Lenze setting

Data on EPM not valid

Data not valid for controller

Data error

OEM data not valid

L

Automatic start inhibited c42 = 0, 2 LOW-HIGH signal change at terminal 28

EPM error EPM missing or defective Power down and replace EPM

Digital inputs not

uniquely assigned

E1...E4 assigned with the same digital

signals

Each digital signal can only be used

once

Either just “UP” or “DOWN” used Assign the missing digital signal to a

second terminal

Dynamic braking fault Dynamic braking resistors are overheating Increase deceleration time

5 Troubleshooting and fault elimination

Loading...

Loading...