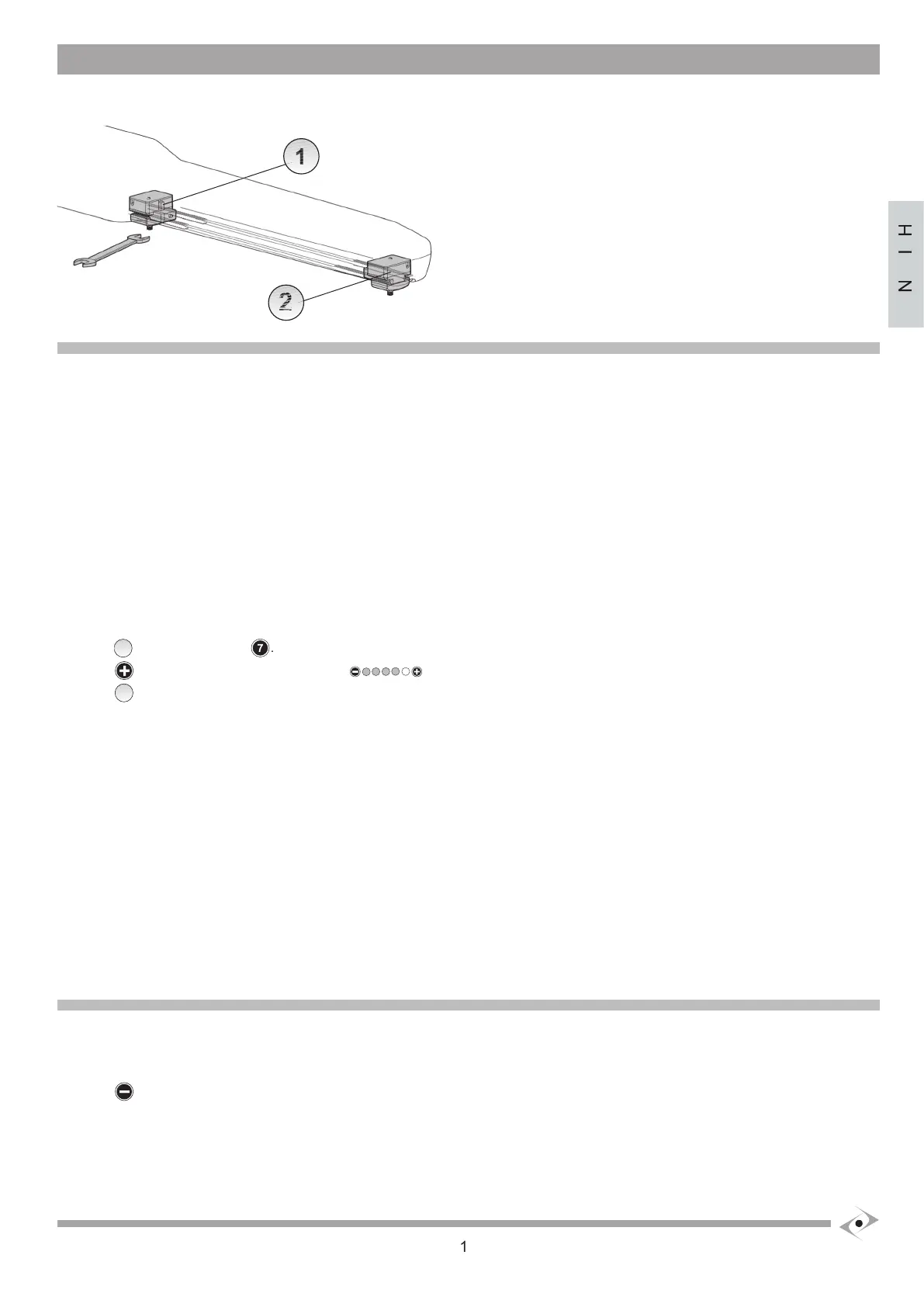

Operators with electric stop switches: direction, travel and speed identifi cation

The direction and travel identifi cation phases are performed at reduced speed.

LEAF 2 CLOSURE STOP SWITCH IDENTIFICATION:

, holding it down until leaf

slowly reaches and pushes for a few seconds against the closure stop plate. Release the step

, when the micro is reached, the red LED

, holding it down until leaf

slowly reaches and pushes for a few seconds against the closure stop plate. Release the step

, when the micro is reached, the red LED

If the gate does not move or struggles to move, it is necessary to raise the force value when the gate is immobile:

to increase the basic force values: the

IDENTIFICATION OF STAGGERING AND OPENING STOP PLATE.

will open. When it reaches the point at which one also wishes to open leaf

will open. The two leafs continue to open slowly.

b) When they have both reached the opening stop plate micros both red LEDs light.

IDENTIFICATION OF CLOSURE STAGGERING AND STOP PLATE

ive and release the step command

will close. When it reaches the point at which one also wishes to close leaf

give and release the step command

will close. The leaves now both move at a normal speed when closing.

b) On reaching the closure stop plate micros, the green LEDS fl ash and the red LEDs remain lit.

The automation is now programmed

. The automation is now in semi-automatic mode by default.

If you are dissatisfi ed with the result obtained,

and repeat procedure from start.

RESETTING THE CONTROL UNIT

Switch off the system’s power supply.

and switch on the system’s power supply until all four LEDs light.

djust the position of the

OPTIMO: ADJUSTING THE OPENING AND CLOSURE MECHANICAL STOP PLATES

Loading...

Loading...