Page 31 of 192

3. Information on specific actuators

The LA20 Inline is a small and compact inline actuator with up to 2500 N in push.

The actuator is equipped with a socket for exchangeable cables and is to be used with

an angled Microfit 30 Deg plug.

Some of the benefits that LA20 Inline offers you:

• Compact and slim design

• Strong lifting load

• Exchangeable cable

• Feedback options for positioning

LA20 is a small inline actuator with a robust design, high efficiency, relatively high load

at 2500 N, feedback signals for positioning and electrical end-stop. It withstands harsh

environments within the medical industry.

The LA20 Inline can be used in various applications where space is limited or where

size is important.

1. LA20 INLINE (MEDLINE

®

CARELINE

®

)

Warnings

• Do not sideload the actuator

• Only use the actuator within specified working limits

• When mounting the LA20 in the application ensure that the bolts can withstand the wear and they are secured safely

• Motor type G and B must only be used with their respective control box types. For further specification se Chapter 3 – Compatibility.

• Motor type B: 24V motor which must be used with COBO, CBJC, CBJ1, CBJ2, CBJH or generally in applications which are mainly battery driven

• Motor type G: 24V. Running mainly on LINAK CB platforms as CO61, CO71, CO41, CA30/40, CB6 OBMe SMPS, CB16 OBF SMPS, CB20

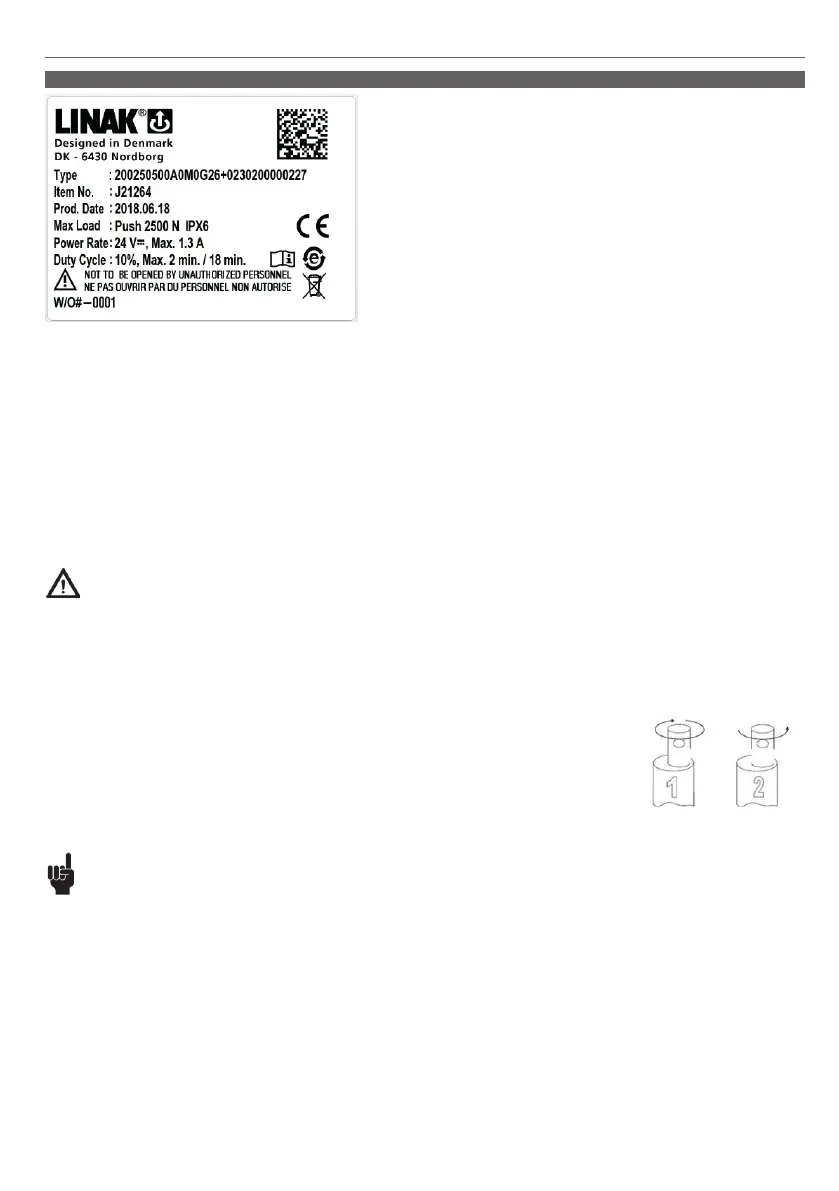

• Instruction concerning the turning of the piston rod eye: When mounting and taking into use, it is not permitted

to make excessive turns of the piston rod eye. In cases where the eye is not positioned correctly, it is permitted

to first screw the eye down to its bottom position, at a maximum torque of 2 Nm (1), and thereafter a

maximum half turn outwards again (2).

Recommendations

• Do not place load on the actuator housing and do prevent impact or blows or any other form of stress to the housing

• Connection bolts must be dimensioned so that they have the necessary strength and tolerance in order to obtain the minimum safety factor according

to the requirements of the authorities

• Ensure that the cable lock is mounted correctly

• Ensure that the cable cannot be squeezed, pulled or subjected to any other stress

• Only use the actuator within the specifications

• Connection bolts and brackets are to be inspected in connection with service and must be replaced if there are signs of wear

• The product must always have the motor short circuited to obtain self-locking according to label value/rated value

• Ensure that the duty cycles and the usage temperatures for LA20 actuators are respected

• The LA20 is not suitable for use in outdoor applications where it can be exposed to sun and rain. If outdoor use cannot be avoided, it is very important

that the LA20 is mounted in a position where it is well shielded. It is up to the customer to provide the shielding. Furthermore, it will be good practice

to ensure that the actuator is fully retracted in the “normal” position. The reason is that there will be a vacuum inside the actuator if it is extended

which over time can lead to water entering the actuator.

• Do not expose the actuator to pull during transport of the application

Usage

• Duty cycle: Max. 10%, 2 minutes continuous use followed by 18 minutes not in use

• Usage temperature: +5 ºC to +45 ºC normal operating temp. -27 ºC to +50 ºC (according to test conditions ISO 7176-9)

• Storage temperature: -40º C to +70º C (according to ISO 7176-9)

• Relative humidity: 20% to 80% at +30° C

• Approvals: IEC60601-1, IEC60601-1-6, ANSI/AAMI ES60601-1, CAN/CSA-C22.2 No. 60601-1

In compliance with ISO 7176-8

• Approvals pending: IEC60601-1, IEC60601-2

• Atmospheric pressure: 800 to 1060 hPa

• Cycles: The LA20 Life cycle test (10.000 cycles) has been performed with a stabilised power supply (10% duty cycle)

on a 120 mm stroke actuator at max. load for the following number of cycles (at ambient temperature)

Loading...

Loading...