Pump Installation 6160 Pump Installation

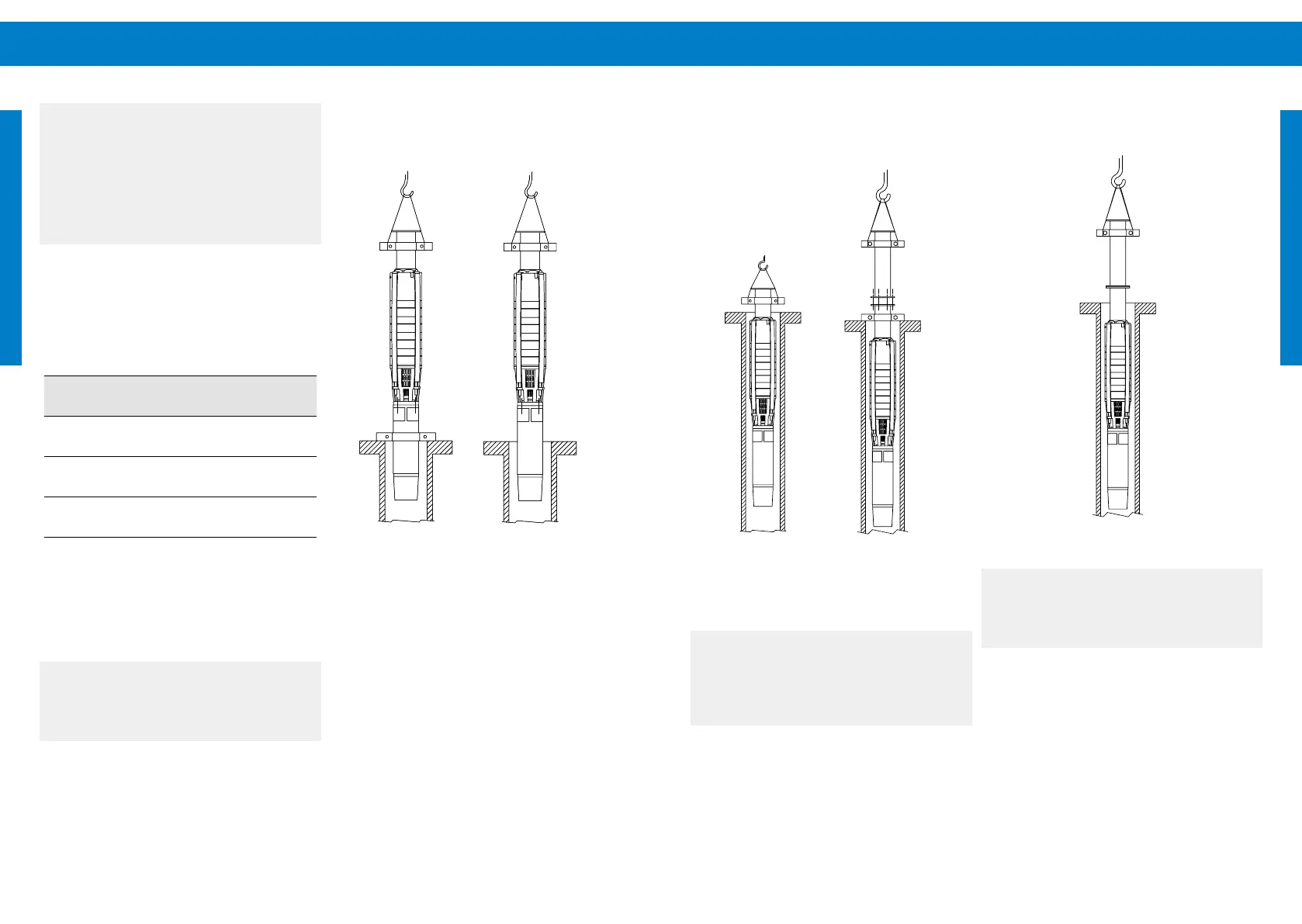

EN ENFigure 29: Connecting the next piece of pipe

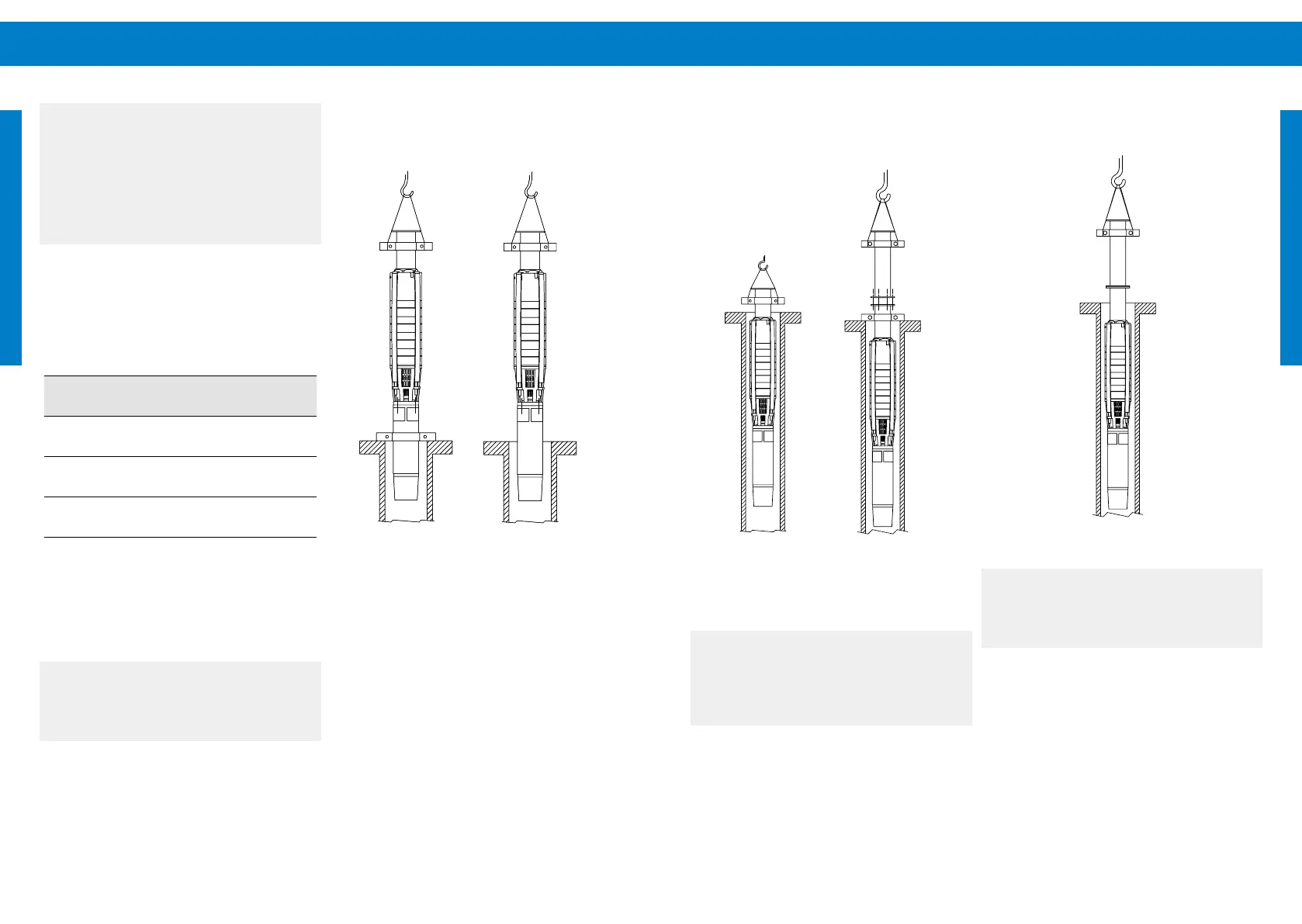

After connecting the two pipes, lift the whole pump

system again to dismantle the lower clamp above

the pump end. This procedure has to be followed for

every piece of pipe until the pump has reached the

desired installation depth.

l

WARNING – If the pump is not lifted

before the clamp is being dismantled the

pump will sag. This could cause serious

injuries to the installer and damage to

the pump system.

a

NOTE - Pay attention to "8.2.4

Preparing the installation" on page

55“and "8.2.5 Installation Depth" on

page 57.

8.2.8 Pipes with thread

If you use pipes with a thread instead of a ange the

installation is basically the same.

The threads have to be sealed with hemp- or teon

tape.

Make sure that the threads cannot work loose over

time.

Figure 30: Dismantling the lower clamp

a

CAUTION – Impact between the pump

end and motor can damage the pump

system.

CAUTION – The NEMA coupling of the

motor and the pump end must be CLEAN

when the pump end is mounted onto the

motor.

For correct connection pay attention to the following

table with tightening torques. The screws must be

tightened diagonally.

Table 12: Tightening torques for pump/motor

connection

Pump / Motor Torque [Nm]

Torque

[lb × ft]

M8 18 13

M12 70 52

M16 150 110

When pump end and motor are assembled, lift the

pump unit a little and remove the lower clamp on the

motor. Now lower the pump carefully downwards

into the bore hole until the upper pipe clamp is

resting properly on the support structure. Be careful

not to allow the pump to hit the side of the well or

this may cause damage.

l

WARNING – Always take suitable

security precautions (like a strong safety

rope) to safeguard the pump against

slipping into the well during installation!

Now the next piece of clamped pipe can be mounted

onto the ange/connector of the previous one. Only

use suitable bolts and sealing material. ("Figure 29:

Connecting the next piece of pipe" on page 61)

Figure 28: Dismantling the lower clamp

Loading...

Loading...