6 Installation Startup and Autotune Guides

38 MAGNETEK HPV1000 AC Elevator Drive Technical Manual

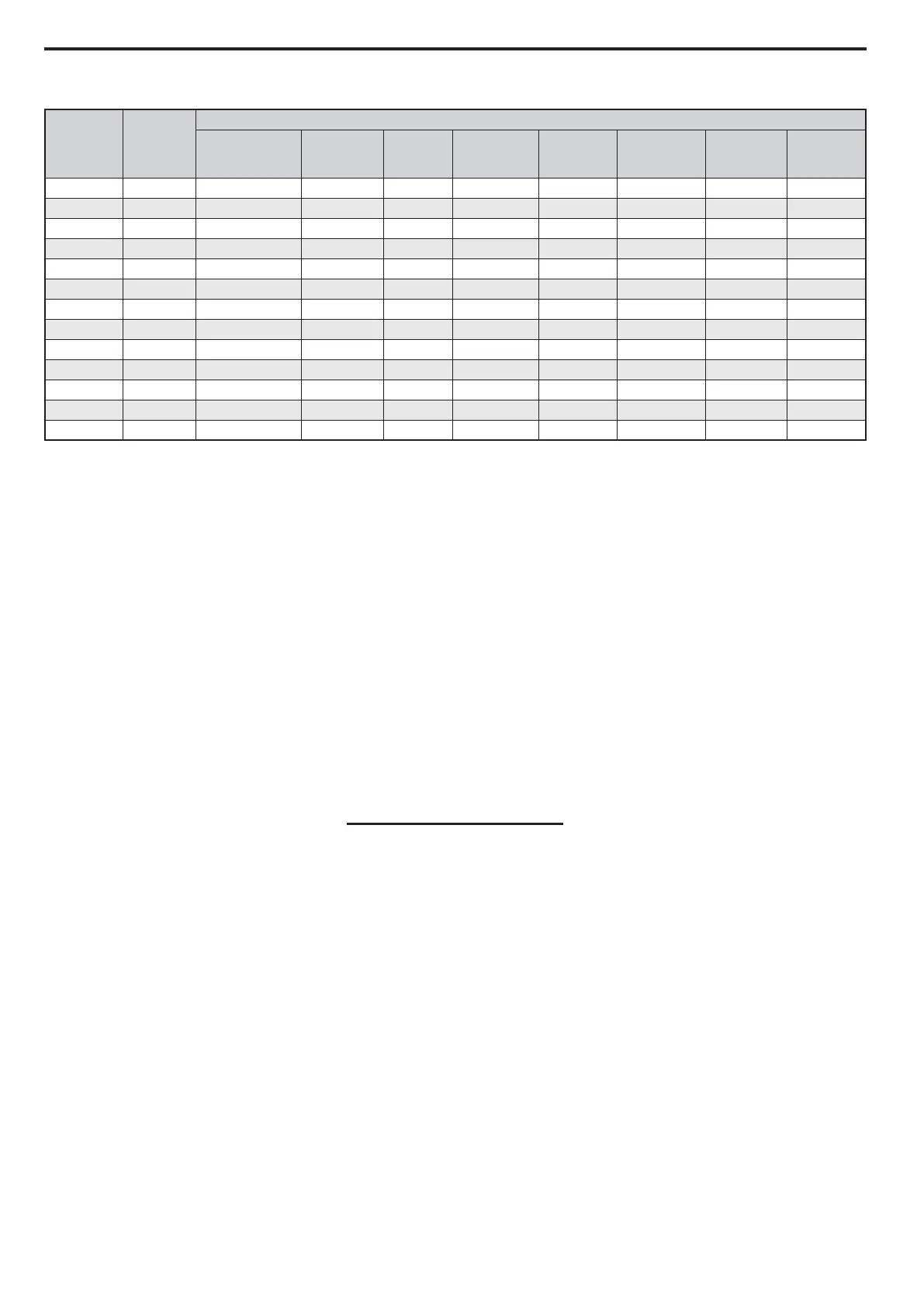

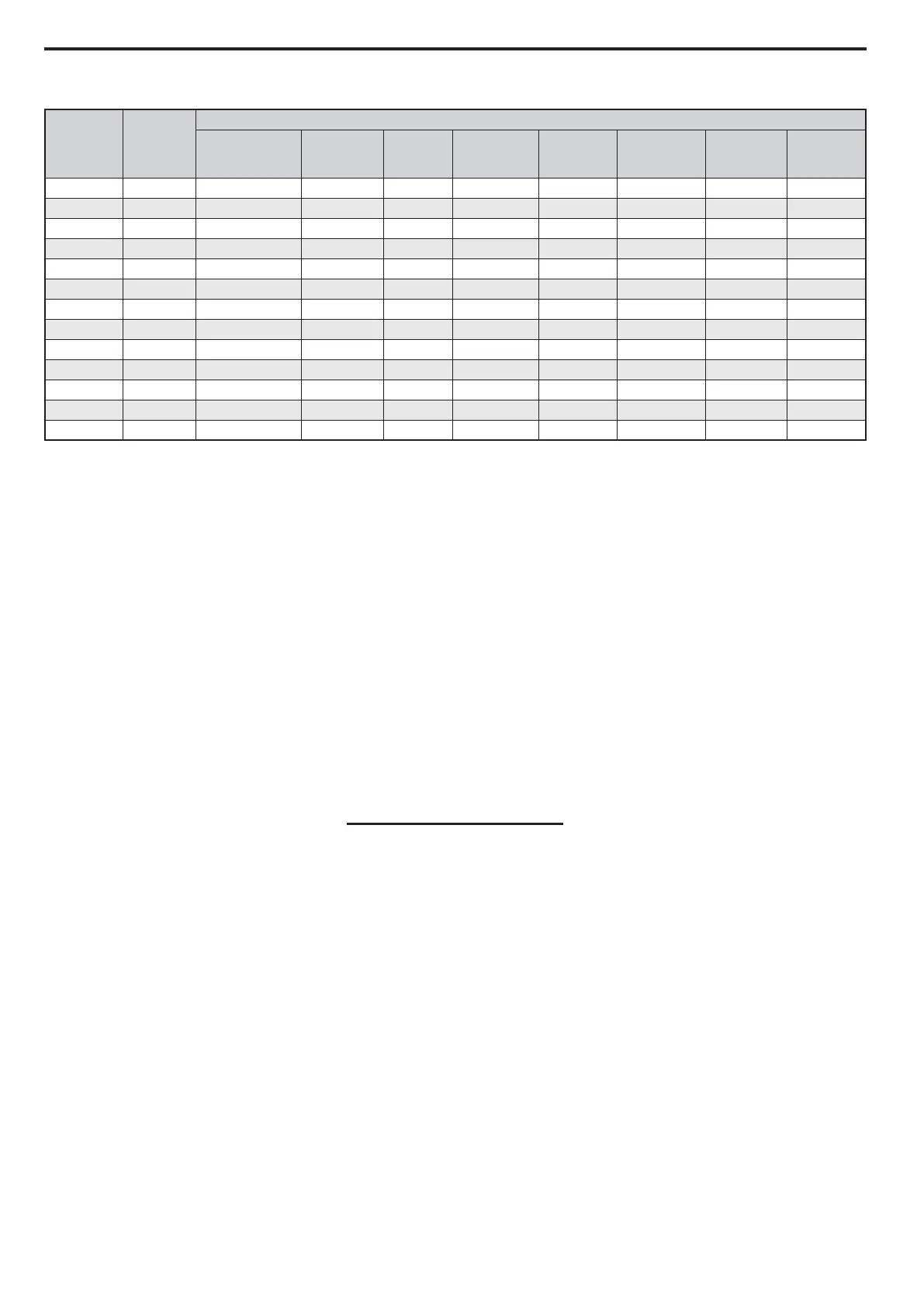

Table 19

Power Up and Parameterization

Enter / verify the hoistway parameters:

• CONTRACT CAR SPD (A1) parameter should be the elevator contract speed in m/s.

• CONTRACT MTR SPD (A1) parameter should be set to an RPM that will make the elevator travel at desired car speed

(measured with hand tachometer).

Note: The above two parameters are utilized by the drive for many purposes regarding speed control of the lift, therefore it is important

these are set correctly.

Enter the Line Voltage in the A4 menu:

• INPUT VOLTAGE (A4) parameter should be set to the measured incoming phase to phase voltage.

When all connections and terminations are made, and the controller switched to ‘Test/Inspection Controls’ you can then

power up the installation. You will next need to verify the parameters entered in the drive match that of the motor data

plate, please do not assume that these are already entered correctly.

You may wish to note your motor data in the adjacent box for reference:

Note: Some motors do not quote the number of motor poles however this can be simply calculated using this formula:

Note: Ensure that the motor connections are phased correctly, that is U, V, W (A, B, C) terminals on the control panel terminal rail are

connected to the hoist motor terminals U, V, W.

The motor data obtained from the motor data plate should now be entered in the A5 menu of the drive. When this is

complete and the control system is prepared to run with any required wiring/links, etc. the encoder alignment can take

place.

In some instances the data on the motor data plate may not be 100% accurate (if the machine is not ‘made to order’ they

may quote the motors maximum values as opposed to what is required for your installation) - if this is the case the

‘calculated’ motor data that matches your installation will have to be obtained from the motor manufacturer and entered

in the drive. This ‘Calculated’ data may have been used to select the drive and the information on the data plate may be

beyond the rating of the drive. It is also important to verify and adjust the CONTRACT MOTOR SPEED parameter in

the A1 Menu of the drive at this stage.

Encoder

Signal

PG-F3

Terminal

Cable Colours

Heidenhain Ziehl CEG

IME

Package

Extension

Wittur

Wittur 2

(Extension)

Sassi

ECN1313

Site

Encoder

A/ A- Yellow & Black Red & Blue Brown Purple Yellow Pink Purple

A A+ Green & Black Grey & Pink White Green Green Grey Red

B/ B- Red & Black Red Yellow Pink Pink Yellow White

B B+ Blue & Black Blue Green Blue Grey Green Brown

Data/ /DT Pink Brown Pink Brown White Brown Blue

Data DT Grey White Grey Grey Brown White Ye ll ow

Clock/ /CK Yellow Black Red White Black Purple Pink

Clock CK Purple Purple Blue Black Purple Black Green

0V Com IG Green & White Pink Purple Yellow Blue Blue Red & Blue

+5V IP Green & Brown Grey Black Red Red Red Grey & Pink

0V Sense IG White Yellow N/A N/A N/A N/A Black

+5V Sense IP Blue Green N/A N/A N/A N/A Grey

Shield FE Shield Shield Shield Shield Shield Shield Shield

120 x Rated Motor Frequency

Rated Motor Speed

Loading...

Loading...