7 Troubleshooting

56 MAGNETEK HPV1000 AC Elevator Drive Technical Manual

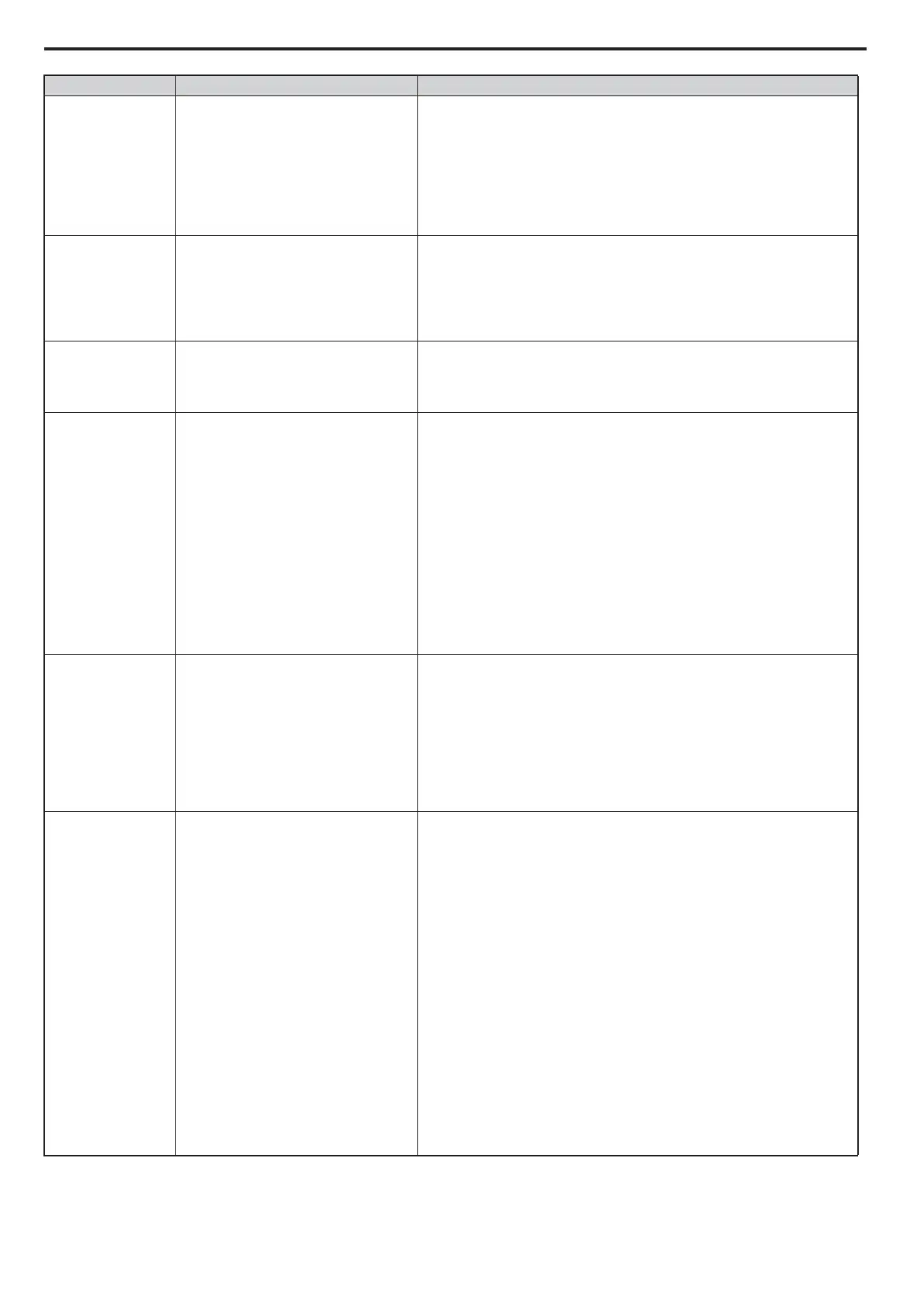

oFC52

CNC Enc Time Flt

Signal encoder timed out waiting to

receive data.

Encoder cable wiring is wrong.

• Correct the wiring.

Encoder cable does not seem to be connected.

• Verify that the encoder card is securely connected.

• Verify that there is no break in the encoder cable.

• Verify that the encoder cable isn’t too long.

Parameters for Encoder Select (C1) are set to the wrong values.

• Set Encoder Select (C1) to the proper setting.

oFC53

CNC Enc Dat Flt

Serial encoder CRC checksum error.

Encoder cable wiring is wrong.

• Correct the wiring.

Encoder cable does not seem to be connected.

• Verify that the encoder card is securely connected.

• Verify that there is no break in the encoder cable.

• Verify that the encoder cable isn’t too long.

oFC54

CNC Encoder Flt

Alarm reading EnDat absolute position

data from encoder (OR flag from EnDat

error for overvoltage, undervoltage, etc.)

Power supply to encoder is wired incorrectly.

• Correct the wiring.

The power supply circuit of the PG option card is damaged.

• Replace the PG option card.

oH

User Overtemp

Overtemp Alarm

The temperature of the heatsink exceeded

the OH Pre-Alarm Lvl (A4).

Parameters are set incorrectly.

• Verify that OH Pre-Alarm Lvl (A4) is not set too low.

Surrounding temperature is too high.

• Check the temperature surrounding the drive. Verify temperature is within

drive specifications.

• Improve the air circulation within the enclosed panel.

• Install a fan or air conditioner to cool the surrounding area.

• Remove anything near the drive that might be producing excessive heat.

Load is too heavy.

• Measure the output current.

• Decrease the load.

• Lower the Carrier Frequency (A4).

Internal cooling fan is stopped.

• Replace the cooling fan, and contact Magnetek to reset maintenance timer.

oH1

Overtemp Flt

The temperature of the heatsink exceeded

the drive overheat level.

Surrounding temperature is too high.

• Check the temperature surrounding the drive.

• Improve the air circulation within the enclosure panel.

• Install a fan or air conditioner to cool the surrounding area.

• Remove anything near the drive that might be producing excessive heat.

Load is too heavy.

• Measure the output current.

• Lower the Carrier Frequency (A4).

• Reduce the load.

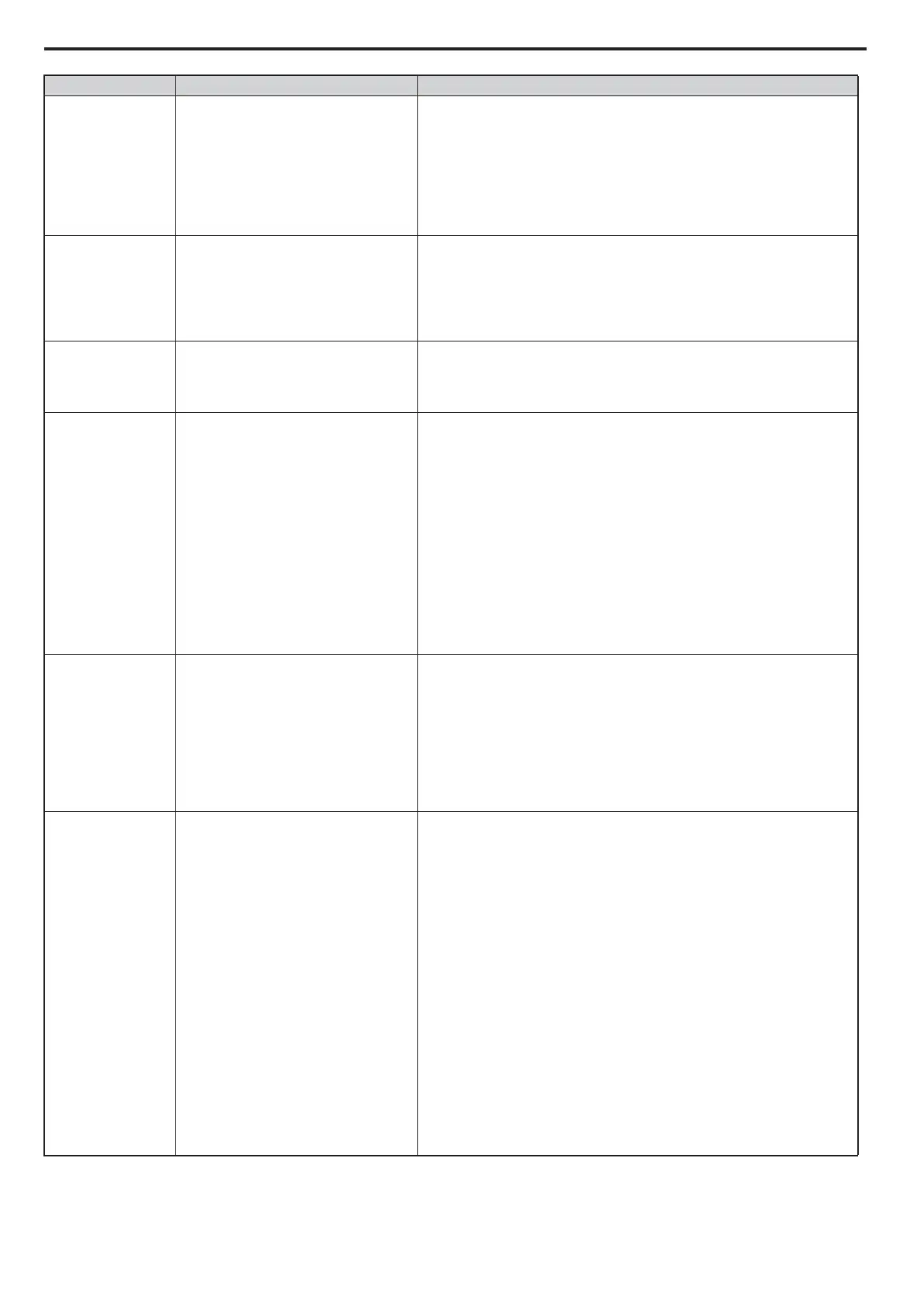

oH3

Motor Overheat Alarm (PTC thermistor

input):

• The motor overheat signal to analog

input terminal A1 or A2 has exceeded

the alarm detection level.

Parameter settings are incorrect.

• Verify that the C5 sub-menu analog input of “Motor PTC” is set correctly.

• Verify that the analog input gain setting and bias offset in the A5 sub-menu

are set correctly: Analog A1 Gain, Analog A1 Bias, Analog A1 Offset,

Analog A2 Gain, Analog A2 Bias and Analog A2 Offset, all of which can

be found in the A5 menu.

Motor thermostat wiring is fault (PTC thermistor input).

• Repair the PTC thermistor input wiring.

Motor has overheated.

• Check the size of the load, the accel/decel times, and the cycle times.

• Decrease the load.

• Lower the acceleration and deceleration in the A2 sub-menu.

• Adjust the preset V/f pattern in the A5 sub-menu.

• Be careful not to lower Motor Mid Volts (A5) and Motor Min Volts (A5)

too much, as this reduces load tolerance at low speeds.

• Check the motor rated current.

• Enter the motor rated current as indicated on the motor nameplate in Rated

Motor Curr (A5).

Ensure the motor cooling system is operating normally.

• Repair or replace the motor cooling system.

Fault Code/Name Description Causes and Solutions

Loading...

Loading...