7 Troubleshooting

62 MAGNETEK HPV1000 AC Elevator Drive Technical Manual

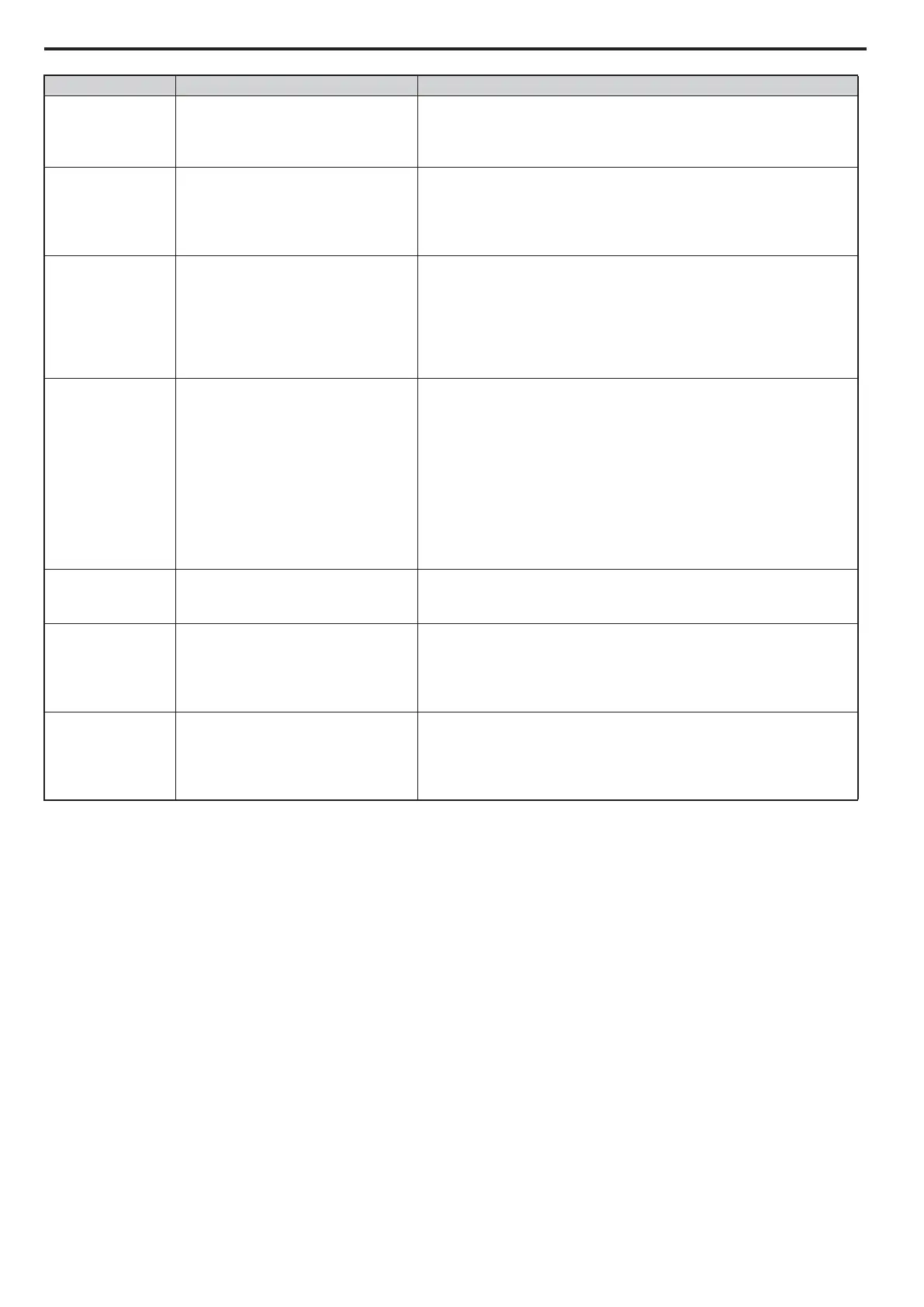

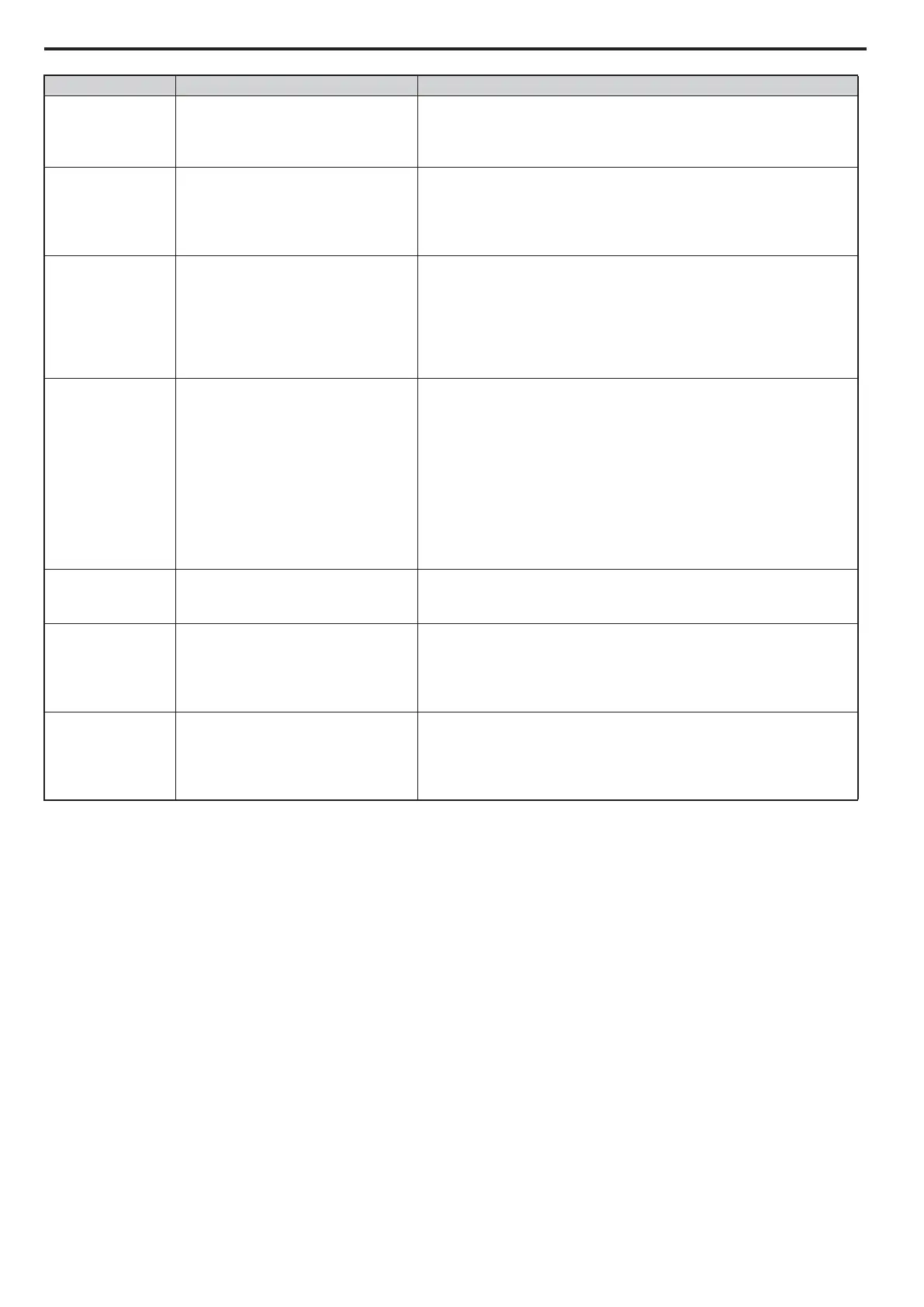

SE3

Current Fault

The output current was lower than 25% of

the motor no-load current during

operation.

The motor contactor is open.

• Check the contactor for any problems.

• Check for any sequencing problems between contact picking and the drive

being told to run.

SE4

Brake Fdbk Flt

The C2 sub-menu input terminal set for

“Brake Monitor NO” or “Brake Monitor

NC” did not respond within the Brake Flt

Time (A1) after an output terminal set for

“Brake Control” closed.

The feedback contact on the brake is defective or the wiring is incorrect.

• Check the brake feedback contact and the wiring.

The brake control circuit does not work properly.

• Ensure the motor brake operates properly with a brake control command

from the drive.

SvE

Pos Lock Fault

Position deviation during Position Lock.

Torque Limit is set too low.

• Set the torque limit to an appropriate value using Mtr Torque Limit (A1)

and Regen Torq Limit (A1).

Excessive load torque.

• Reduce the amount of load torque.

Noise interference along encoder wiring.

• Check the encoder signal for noise reference.

STo

PM Stall Flt

Motor pull out or step out has occurred.

Motor has exceeded its pull out torque.

The wrong motor code has been set (only used for motor by drive

manufacturer).

• Enter the correct motor code for the PM being used into the A5 sub-menu.

• For special-purpose motors, enter the correct data to all parameters in the

A5 sub-menu according to the Test Report provided for the motor.

Load is too heavy.

• Reduce the load.

• Increase the motor or drive capacity.

Accel/decel ramp is too short.

• Lower the acceleration and deceleration in the A2 sub-menu.

• Lower the jerk setting in the A2 sub-menu.

TrPC

IGBT Alarm 2

IGBTs have reached 90% of their

expected performance life.

IGBTs have reached 90% of their expected performance life.

• Replace the drive.

UL3

Undertorque 1

Undertorq 1 Alm

The current has fallen below the

minimum value set for torque detection.

Should you need to adjust these factory

determined values, contact Magnetek for

more details.

Parameter settings are not appropriate for the load.

• Check the settings of parameters.

There is a fault on the machine side.

• Check the load for any problems.

UL4

Undertorque 2

Undertorq 2 Alm

The current has fallen below the

minimum value set for torque detection.

Should you need to adjust these factory

determined values, contact Magnetek for

more details.

Parameter settings are not appropriate for the load.

• Check the settings of parameters.

There is a fault on the machine side.

• Check the load for any problems.

Fault Code/Name Description Causes and Solutions

Loading...

Loading...