AXLES/DRIVE SHAFTS/WHEELS AND TIRES 5540F/YB5515 SERVICE MANUAL

8-16 Published 10-21-2010, Control# 198-04

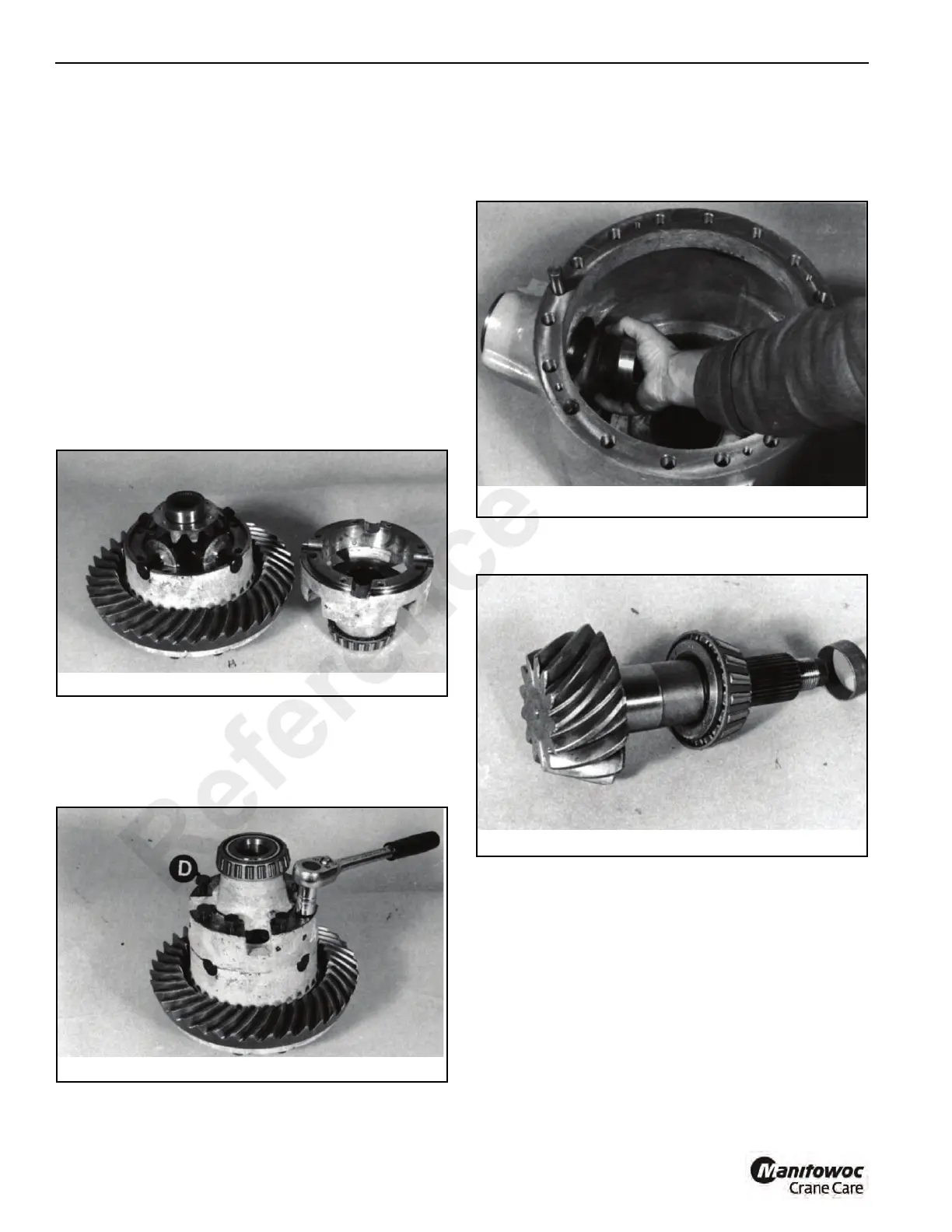

Assembly Procedures

NOTE: The crownwheel and pinion are matched and

should be replaced as a set, if either one is

damaged or excessively worn.

The two differential case halves are also matched,

as are the differential side gears and planet gears.

Do not use unmatched case halves or gears.

NOTE: Make sure all bearings are lightly oiled before

installing and setting. Make sure to rotate bearings

while setting.

1. If required, install the crownwheel to the differential case

half. Tighten the crownwheel retaining bolts to a torque

of 122 lb-ft (166 Nm).

Assemble the differential gears and their spherical

washers into the bottom half housing Figure 8-31. Install

the differential bearing cones.

2. Position the top half housing onto the differential,

aligning the match mark letters. Apply Loctite 242 to the

threads of bolts D Figure 8-32. Install the bolts and

tighten to a torque of 42 lb-ft (56 Nm). Check the gears

for free rotation.

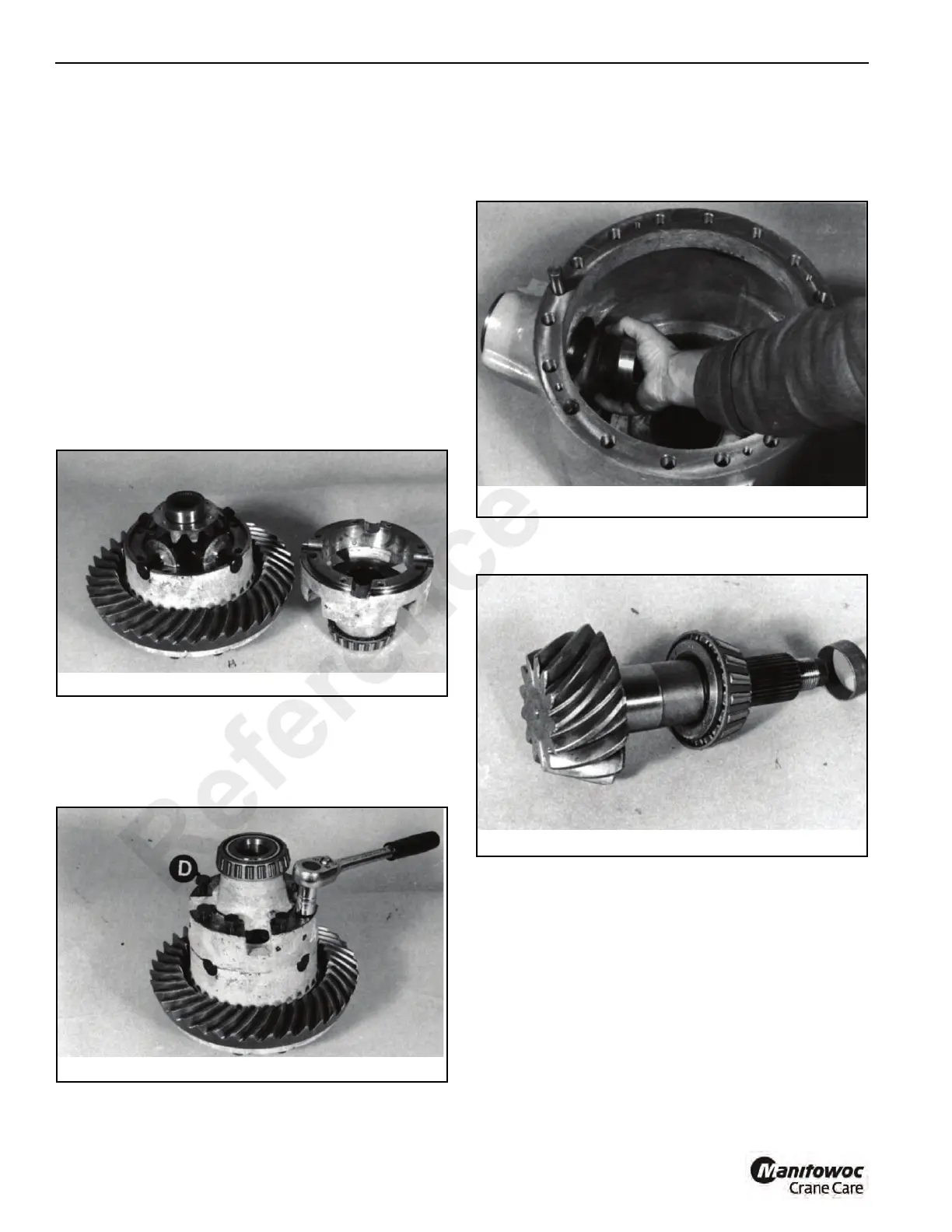

3. Install the pinion bearing cup Figure 8-33, together with

the required thickness of shims to give correct pinion

depth (see Pinion Depth on page 8-14). To ensure that

cup is installed square, use a suitable puller assembly.

Do not use a hammer. Install the outer bearing cup.

4. Install the pinion inner bearing cone Figure 8-34 and a

new collapsible spacer.

Reference Only

Loading...

Loading...