40

D00619EN - v0 SWING OPERATOR - INSTALLATION MANUAL

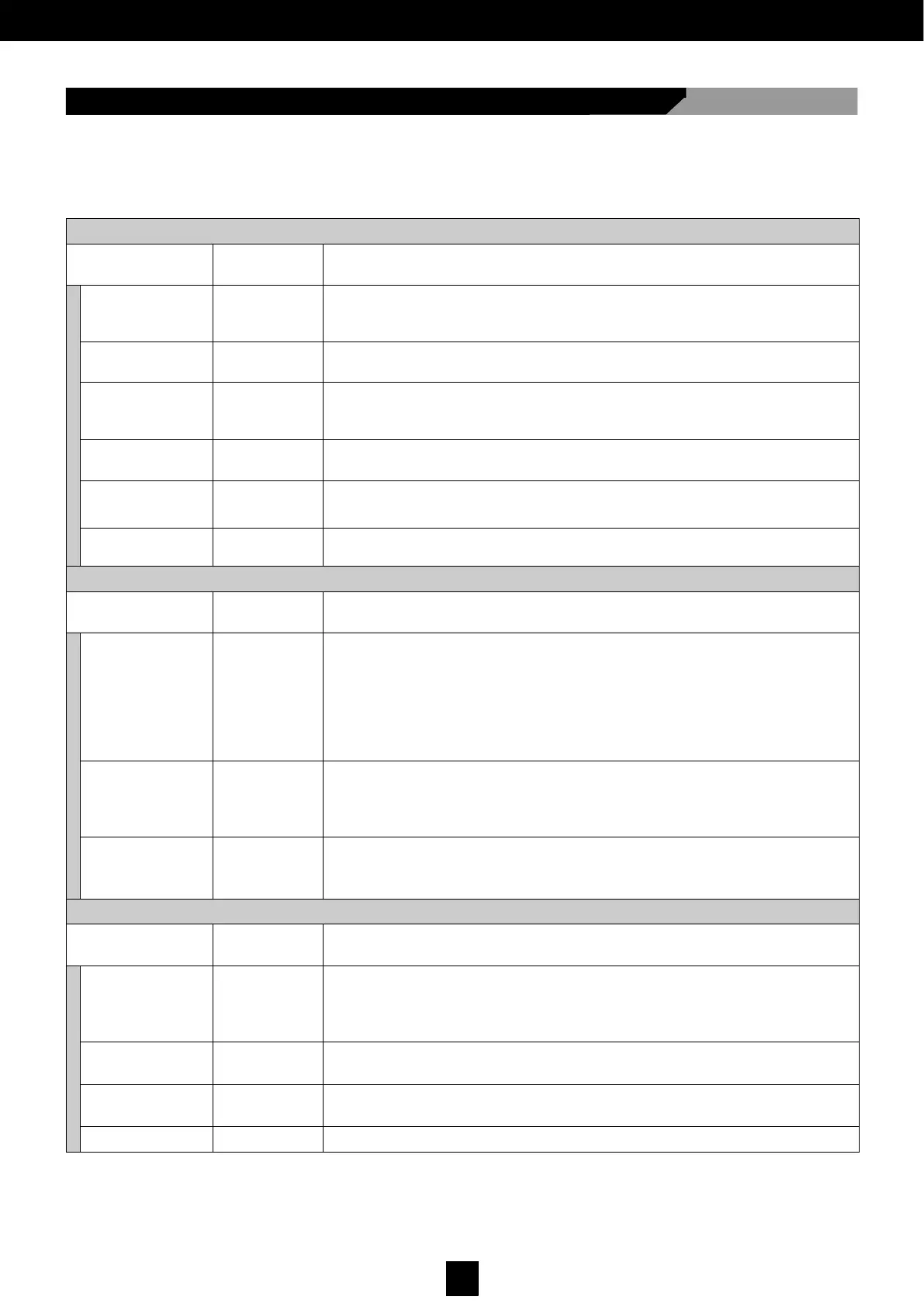

7.4 Risk Assessment

MECHANICAL HAZARDS

Risk Dangerous

Area

Risk Prevention Measures

Structural

Machine area Assess the suitability of the structure where the machine is going to be installed:

a levelled floor with sufficient load capacity, no obstacles in the transit area,

firm ground free of irregularities, etc.

Stability

Machine area Attach the different machine parts in a stable way, using appropriate materials and strictly

adhering to the indications in this manual

Shearing, Cut or

Severing

Closing area

• Do not use float glass to manufacture/repair the leaves of the machine.

• Check that there are no burred or sharp edges on any of the different door parts.

Dragging and

entrapment

Inside the

operator

Do not manipulate the interior of the operator while it is in operation.

Impact and

crushing

Closing area

• Adjust the closing force of the machine to a value appropriate for its operation.

• Verify the correct operation of the safety photocell barriers.

Crushing

Machine area Exercise great caution when placing the leaf in its final location.

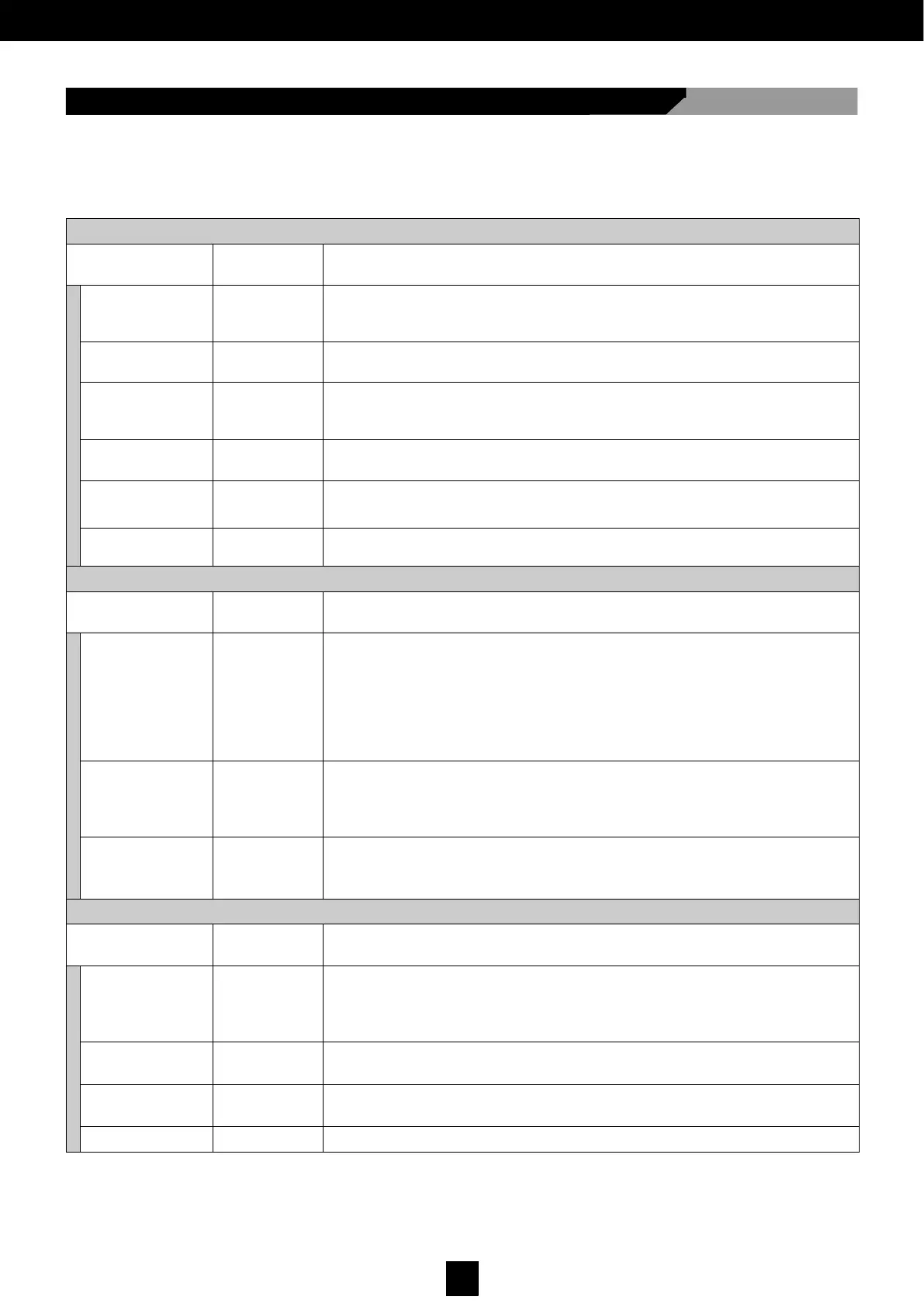

ELECTRICAL HAZARDS

Hazard Dangerous

Area

Risk Prevention Measures

Direct or indirect

contact

Inside the

operator

• Use components and electrical materials with CE marking.

• Connect the electrical connections, the mains connection, the earth connection and verify

all connections following the indications in the wiring and connections manual.

• Ensure the continuity of the conductors by using cables with sharp edges.

• Perform all maintenance and adjustment tasks by strictly adhering to the specifications in

this manual.

Electrical energy

dispersal

Operator

• Follow the technical instructions applicable under the low-voltage electrotechnical

regulations.

• Connect the electrical connections, the mains connection, the earth connection and verify

all connections following the indications in the wiring and connections manual.

Electromagnetic

compatibility

hazards

Operator

• Use components and electrical materials with CE marking.

• Connect the electrical connections, the mains connection, the earth connection and verify

all connections following the indications in the assembly manual.

HAZARDS RELATED TO CONTROL AND SAFETY DEVICES

Hazard Dangerous

Area

Risk Prevention Measures

Opening controls

Door area

• If manual controls are installed, place them correctly, protected from possible unauthorised

or malicious use.

• Check and install the photocells following the instructions in the assembly, connection and

wiring manuals.

Lack of power

Door area

• Check that the door operates safely again after the power supply has been interrupted.

Confinement

Door area

• Check that the panic break-out system works properly and ensure that the door opens after

power supply failure.

Below, there is an outline of the different hazardous situations that may arise with our machines after leaving the factory, either

during the installation process, commissioning, maintenance, adjustment or disassembly. There is also reference to the risk

minimisation measures that must be taken during the aforementioned phases of the machine’s life:

Loading...

Loading...