6A-34 POWER TRIM 90-13645--2 495

4. Install pin. Drive pin in until flush.

Install Power Trim assembly on engine, refer to

“Installation” instructions in “Power Trim Assem-

bly Removal and Installation,” preceding.

51356

a

a - Pin (Drive Against Knurled End)

Pump Replacement

IMPORTANT: The pump is not rebuildable. If pump

is defective, replace as an assembly.

NOTE:

Power Trim assembly does not have to be re-

moved from engine to replace pump.

1. Disconnect trim pump motor wires, and remove

starboard transom bracket from engine; refer to

“Removal” instructions in “Power Trim Assembly

Removal and Installation,” preceding.

Unseat motor and pump assembly from housing

as follows:

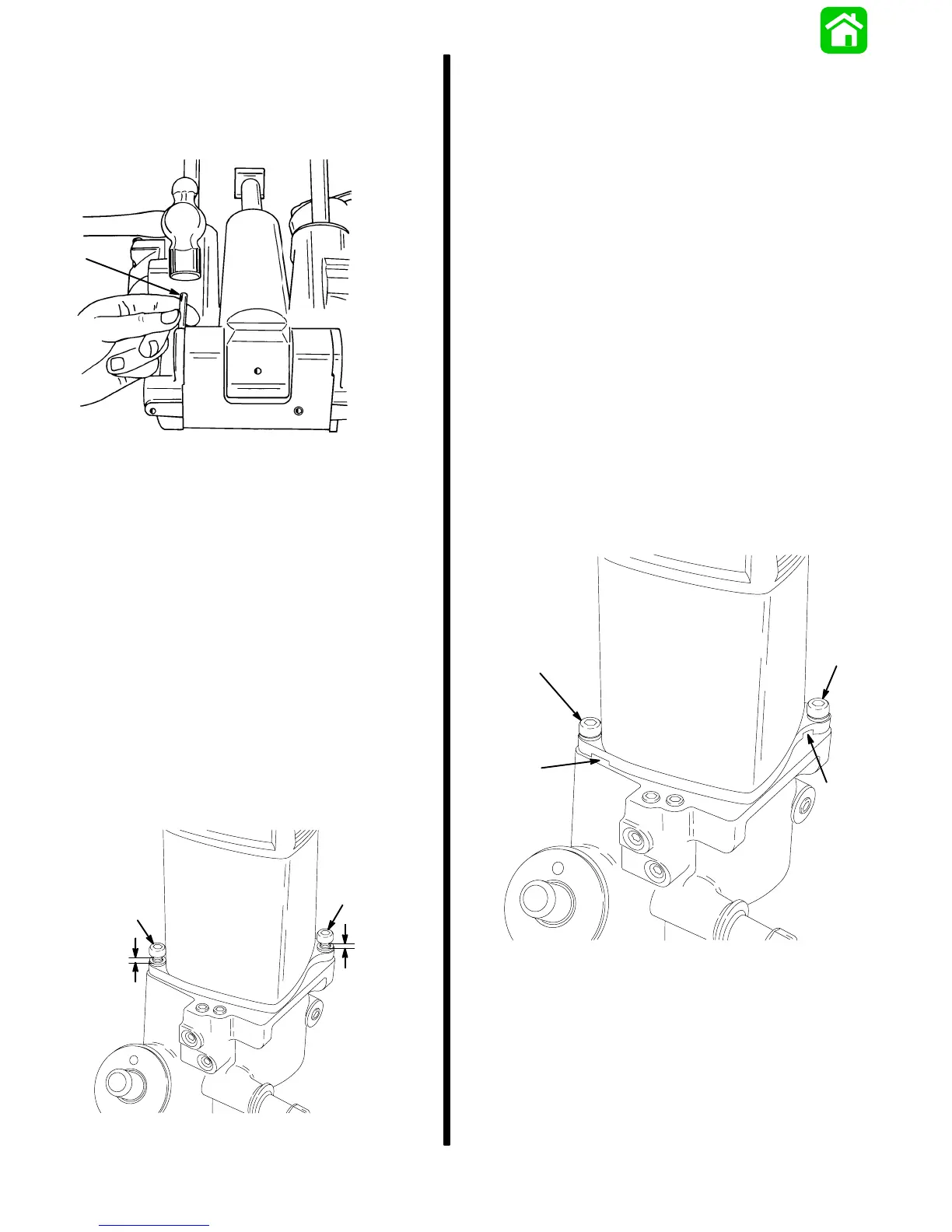

OPERATIVE TRIM MOTOR

Loosen 2 bolts until 1/4 (6mm) of each bolt is ex-

posed. Do not remove bolts.

18458

a

a

1/4″

1/4″

a - Bolts

Tighten manual release valve to full right (clockwise).

Operate trim motor in “Up” direction by connecting

trim motor wires to a 12-volt battery [BLUE wire to

POSITIVE (+) terminal and BLACK wire to

NEGATIVE (–) terminal].

Slowly remove fill screw to bleed pressure from

reservoir.

From a full closed (clockwise) position, slowly turn

manual release valve counterclockwise four turns to

bleed remaining pressure from system.

Remove 2 bolts and lockwashers.

Lift motor and pump assembly from housing.

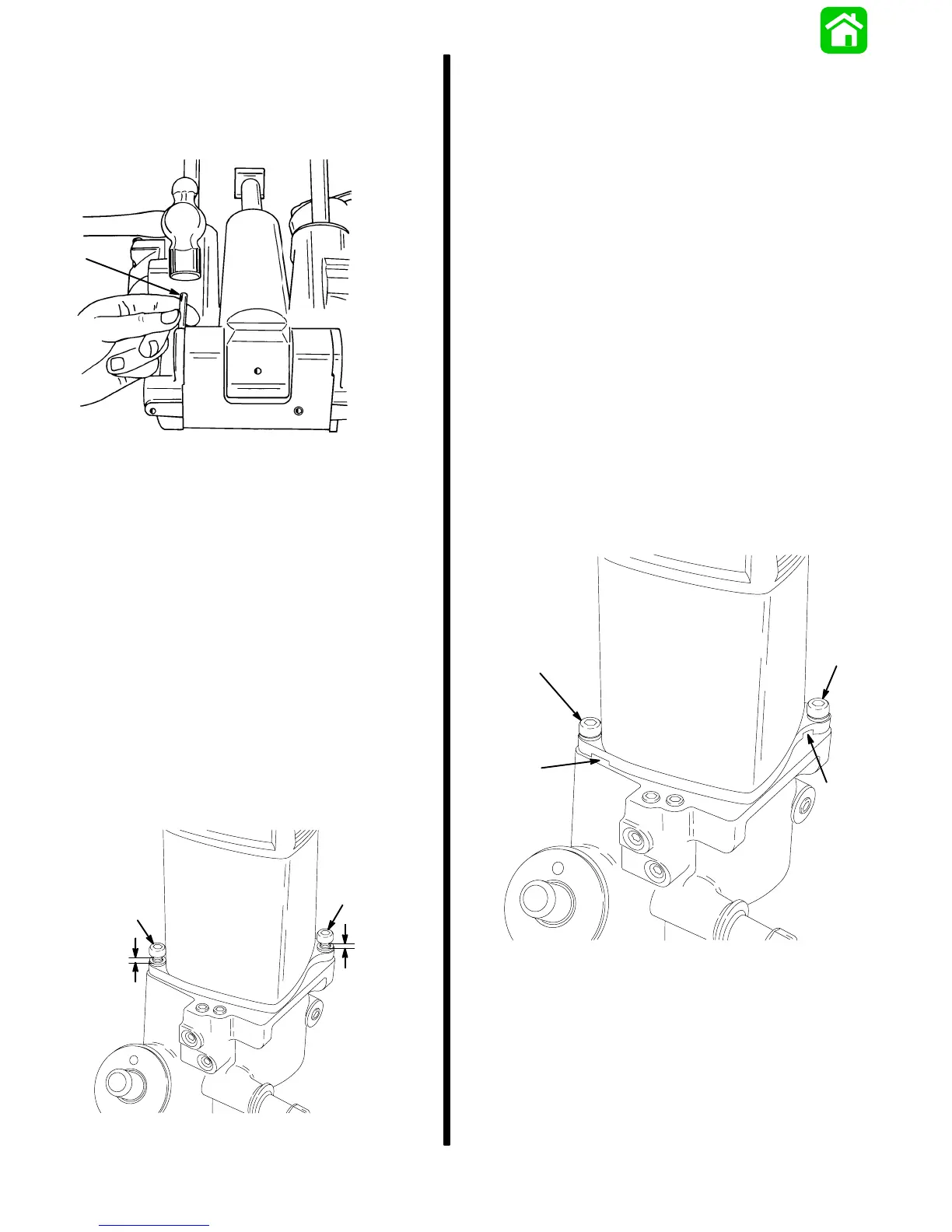

INOPERATIVE TRIM MOTOR

Slowly remove fill screw to bleed pressure from

reservoir.

From a full closed (clockwise) position, slowly turn

manual release valve counterclockwise four turns to

bleed remaining pressure from system.

Remove 2 bolts and lockwashers.

Using 2 screwdrivers, pry up on motor at slots.

18461

b

c

b

c

b - Bolts

c - Slots

Loading...

Loading...