MXIII SINGLE PROGRAMMING GUIDE

MAINTENANCE

46

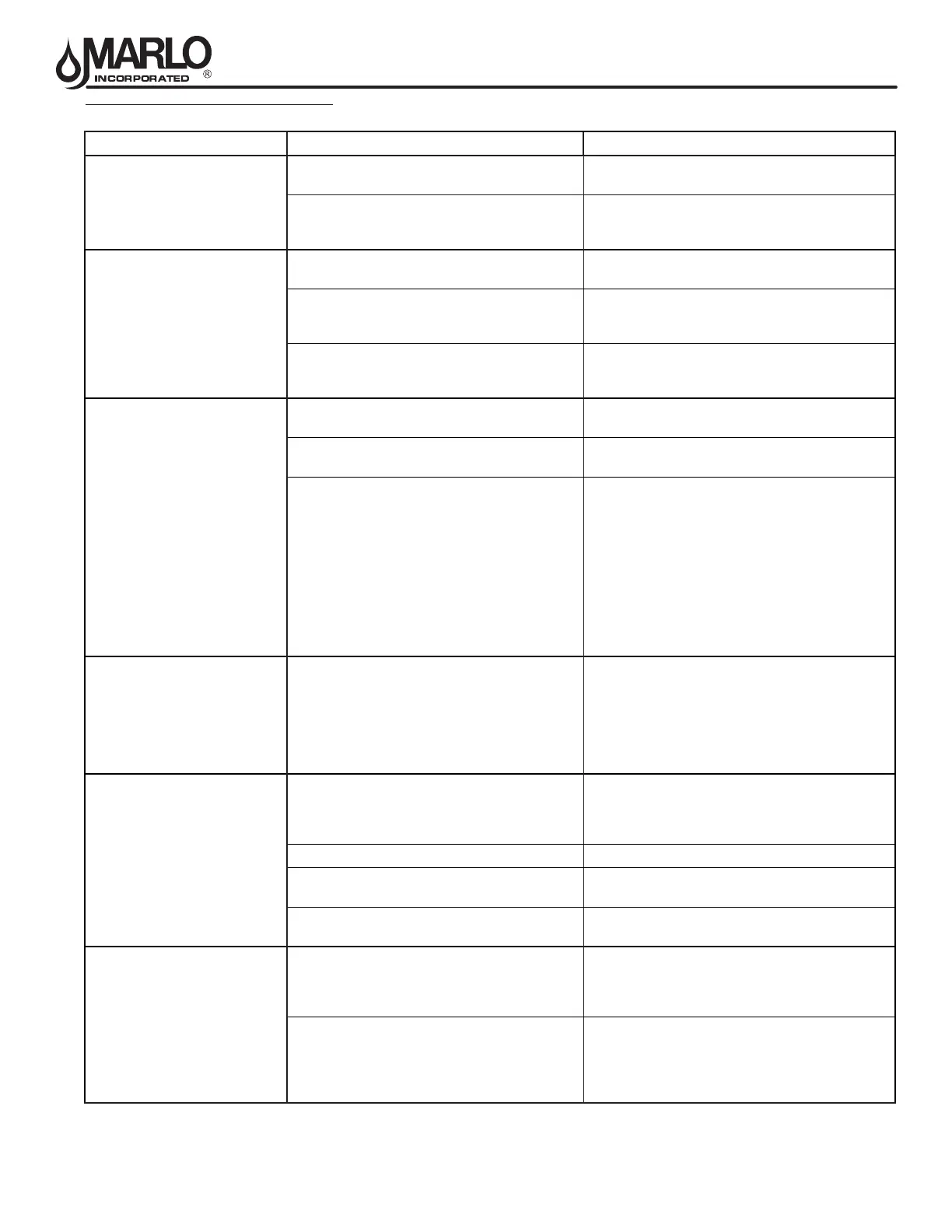

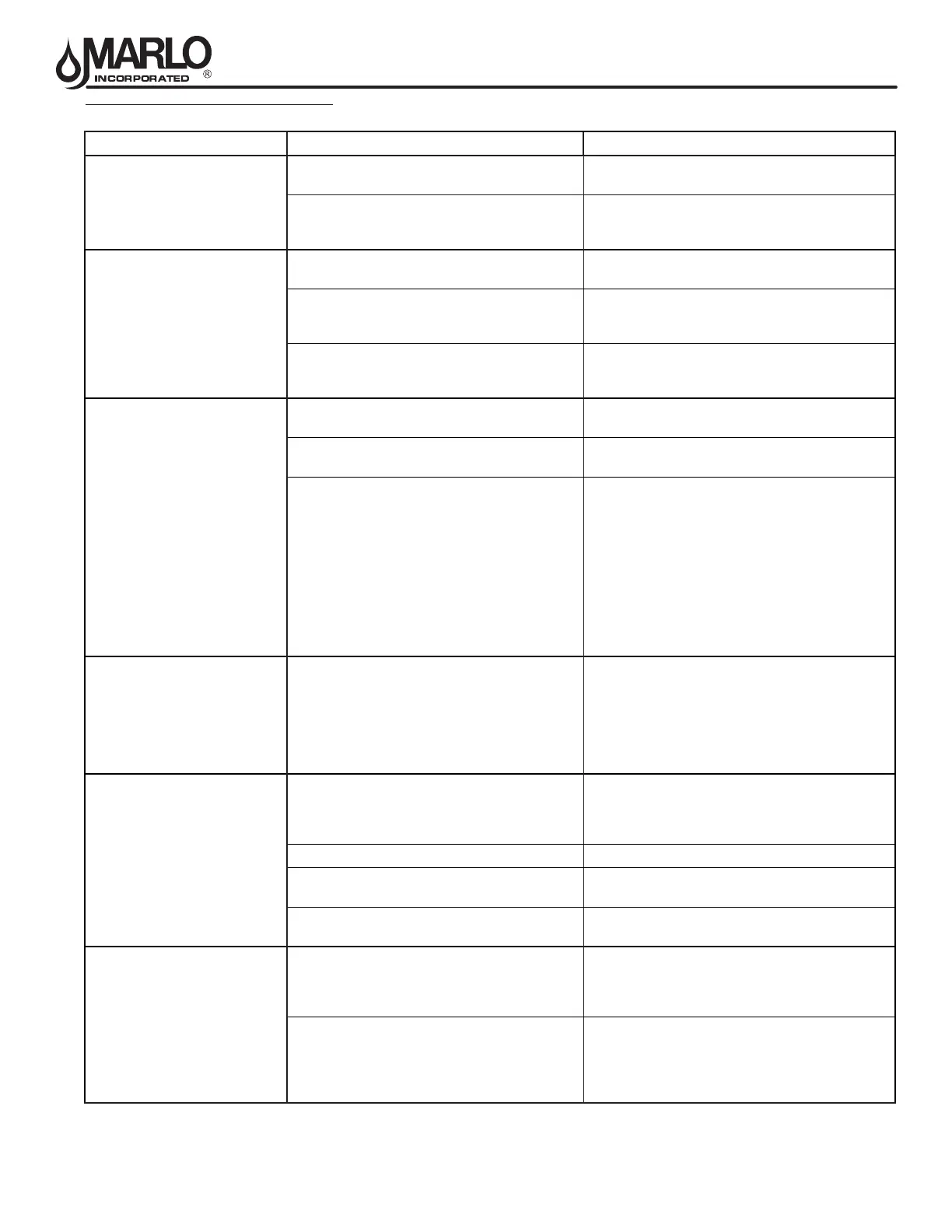

PROBLEM/SYMPTOM PROCEDURE POSSIBLE CAUSE

1. Slight leak to drain. A. Disconnect tubing at backwash

control

A. Flow indicates leaky seal in stager

valve.

B. If stager is not leaking, use soap test

kit and check hardness of water at

drain.

B. If water tests soft, Valve #6 is

leaking: If water tests hard, Valve #3.

See Problem 5

2. High ow to drain

during service.

A. Check position dial. A. If not in position #4, rotate stager

clockwise to this position.

B. If position dial is in #4, check for

water leakage from Valve #3 or Valve

#6 vent holes.

B. Leakage indicates:

1. Ruptured diaphragm

2. Loose diaphragm nut

C. If vent hole is not leaking, use soap

test kit and check hardness of water

at drain.

C. If water tests soft, Valve #6 is open:

If water tests hard, Valve #3.

See Problem 5

3. Failure to draw brine. A. Check that manual brine valve is

open wide.

A. Valve must be open at all times, except

when servicing.

B. Check water pressure. B. Water pressure must be a least 30 psi

during regeneration.

C. Turn position dial clockwise to

position #2. Break union in suction

line to injector and feel for suction.

C. If there is suction, automatic brine

valve may be clogged.

No suction indicates:

1. Drain pipe to small or discharging at

level too high above oor.

2. Plugged pilot strainer.

3. Plugged injection nozzle.

4. Valves #1, #4, or #2 not closing fully.

See Problem #5

5. Plugged backwash controller.

6. Dirty mineral bed.

4. Slight leak from vent

hole.

A. Turn position dial clockwise to a

position, which relieves pressure on

valve.

A. If leaking stops, there is possibly a

loose diaphragm nut, a small Tear

in diaphragm, or the washer under

diaphragm is missing. If leaking

does not stop, shaft guide O-ring is

damaged, shaft guide is not seated

against gasket, or shaft is damaged.

5. Diaphragm valve

does not close or

seat completly.

A. Check that vent hole is not plugged. A. If vent hole is plugged, air in space

between diaphragm and shaft guide

will compress and prevent valve from

closing.

B. Check for water leak at vent hole. B. See Problem #4

C. Loosen tubing nut at diaphragm cap. C. If there is no ow, pilot strainer may be

plugged.

D. Turn o water pressure and

disassemble diaphragm valve.

D. Seat washer may be dirty, worn or

loose. Seat may be eroded.

6. Diaphragm valve

does not open.

A. Check that vent hole is not plugged. A. If vent hole is plugged, a partial

vacuum will be created in the space

between the diaphragm and shaft

guide, preventing valve from opening.

B. Loosen tubing nut at diaphragm cap. B. Check for ow

1. If there is ow, stager valve is

leaking.

2. If there is no ow, tubing tting may

be plugged.

TROUBLESHOOTING SOFTENER

Loading...

Loading...