MXIII SINGLE PROGRAMMING GUIDE

MAINTENANCE

47

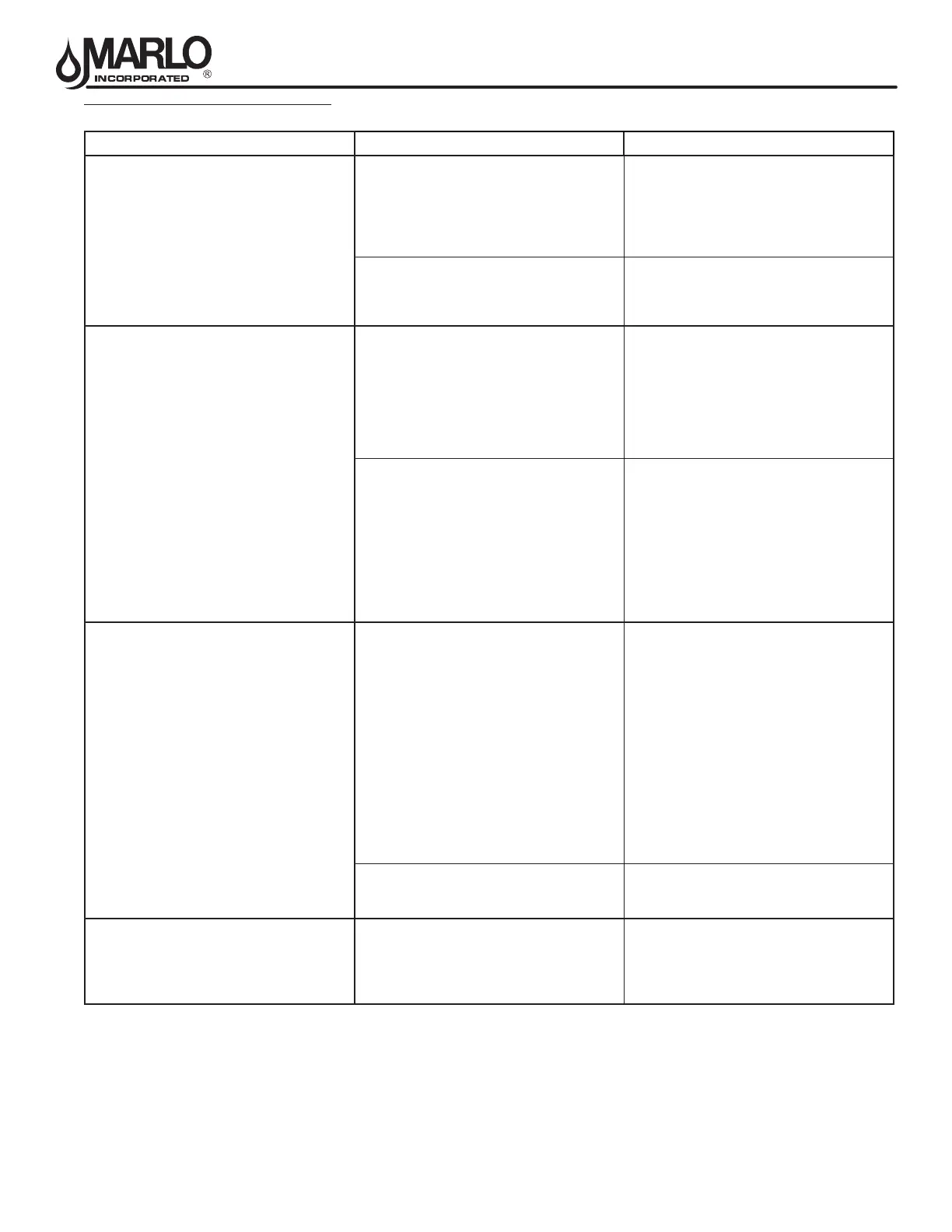

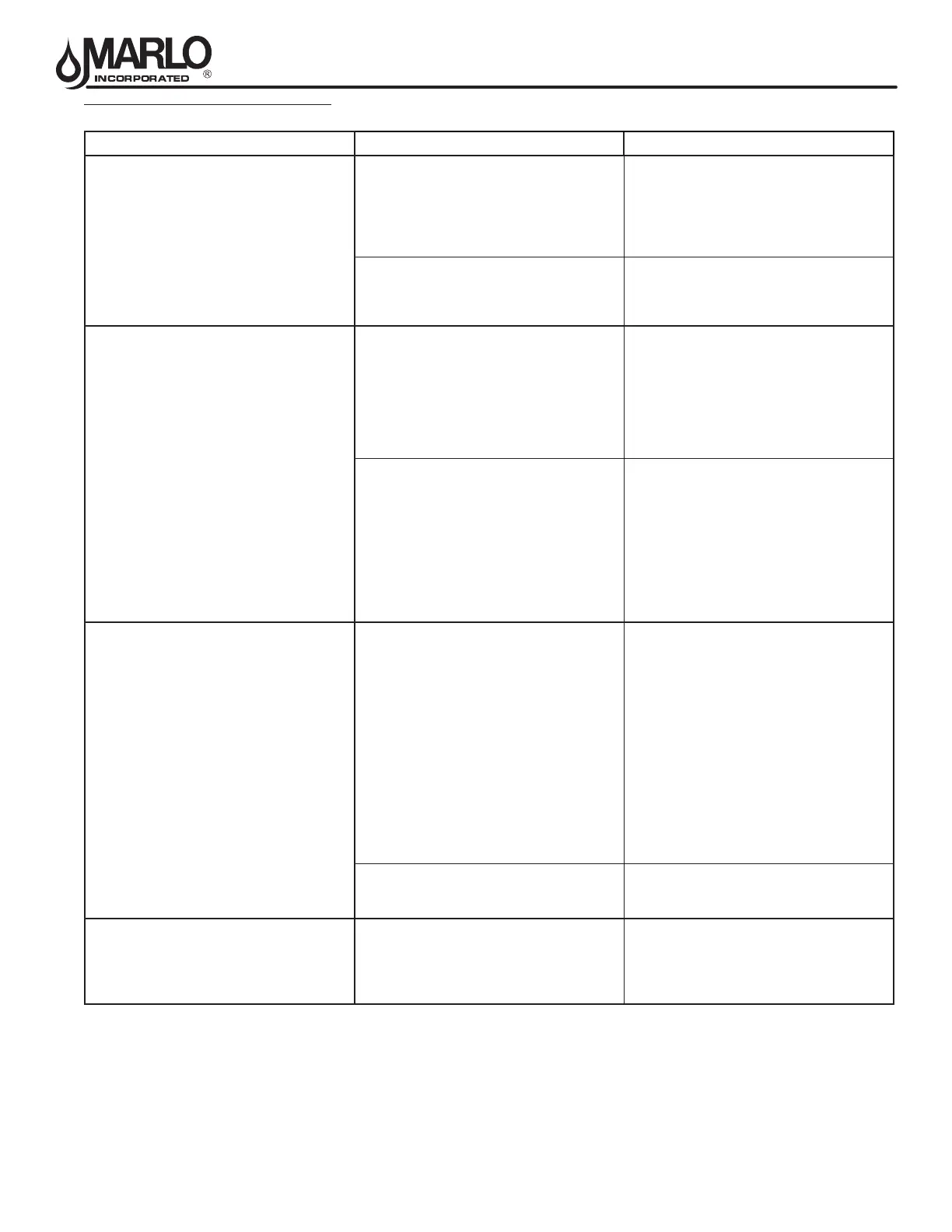

PROBLEM/SYMPTOM PROCEDURE POSSIBLE CAUSE

7. Hard water leakage into

service lines.

A. Close inlet and outlet valves and

inspect by-pass valve.

A. Examine valve

1. Seat washer may be loose or

worn.

2. Seat may be rough.

3. Shaft orice plugged.

4. Diaphragm ruptured.

B. Check that Valve #4 is seating. B. See Problem 5.

8. Restricted or no drain ow

during backwash.

A. Either Valve#1 or Valve#2 is

not opening fully. To determine

which one: Turn position dial to

position #1 and then to position

#3. Compare ow at drain.

A. Flow should be the same for both

positions.

1. If no dierence is noted, valve

#4 is not opening properly.

2. If backwash ow is higher,

valve #1 is not opening

properly.

See problem #7.

B. Turn position dial to position #1

and then position #3. Compare

ow at drain.

B. Flow should be the same. If ow

for position also is low.

1. Inlet water pressure may be

low.

2. Backwash ow control may be

plugged.

3. If position #3 ow rate is

higher, either valve #4 or valve

#3 is not opening.

See problem #7.

9. Loss of softening resin

(evidence of resin in drain

lines).

A. Open vent in top of softener tank

and check for air in tank.

A. If air is present

1. Vent completely and recheck

prior to next regeneration.

2. If recheck discloses a

recurring build-up of air, check

brine system(s) for possible

leaks in suction line or brine

valve not seating properly.

3. If brine system is functioning

properly source of air may

be in the water supply to

unit. Use of an automatic air

relief valve is indicated in this

situation (consult factory for

recommendation).

B. Check automatic backwash

control valve for rate of ow in

excess of listed ow (gpm)

B. Check for excessive inlet water

supply pressures– reduce to

rated pressure.

10. Loss of softening resin

(evidence of resin and/or

gravel in service lines.

A. Check for damage to softener

under-drain system.

A. Investigation of damage to

under-drain generally requires

unloading of softener tank.

Consult factory for recommended

procedures before proceeding.

TROUBLESHOOTING SOFTENER

Loading...

Loading...